3-36 2007 Buell Lightning: Engine

HOME

NOTES

● Depending on the type of crowsfoot being used to torque

the oil lines it may be necessary to remove the oil filter in

order to properly torque certain oil line fittings.

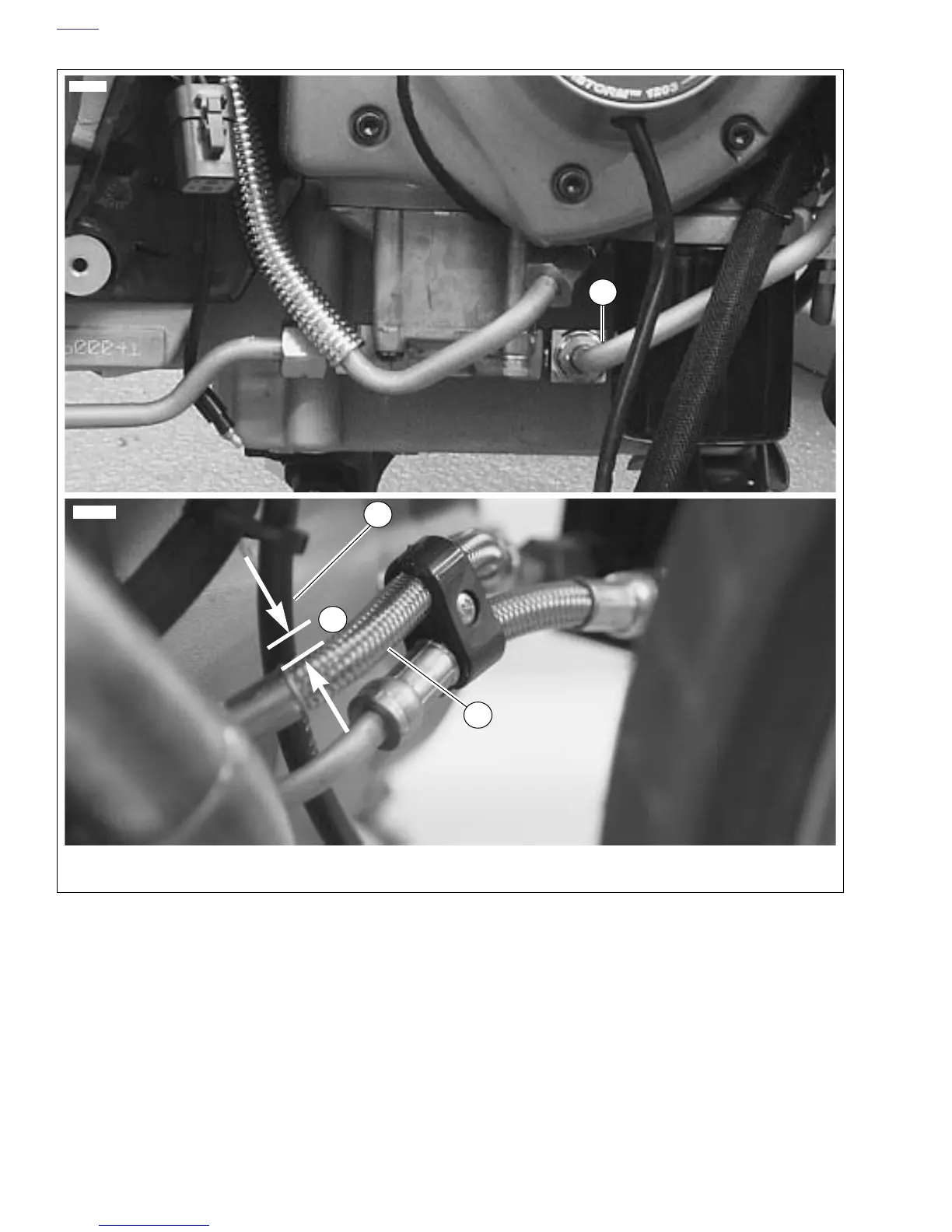

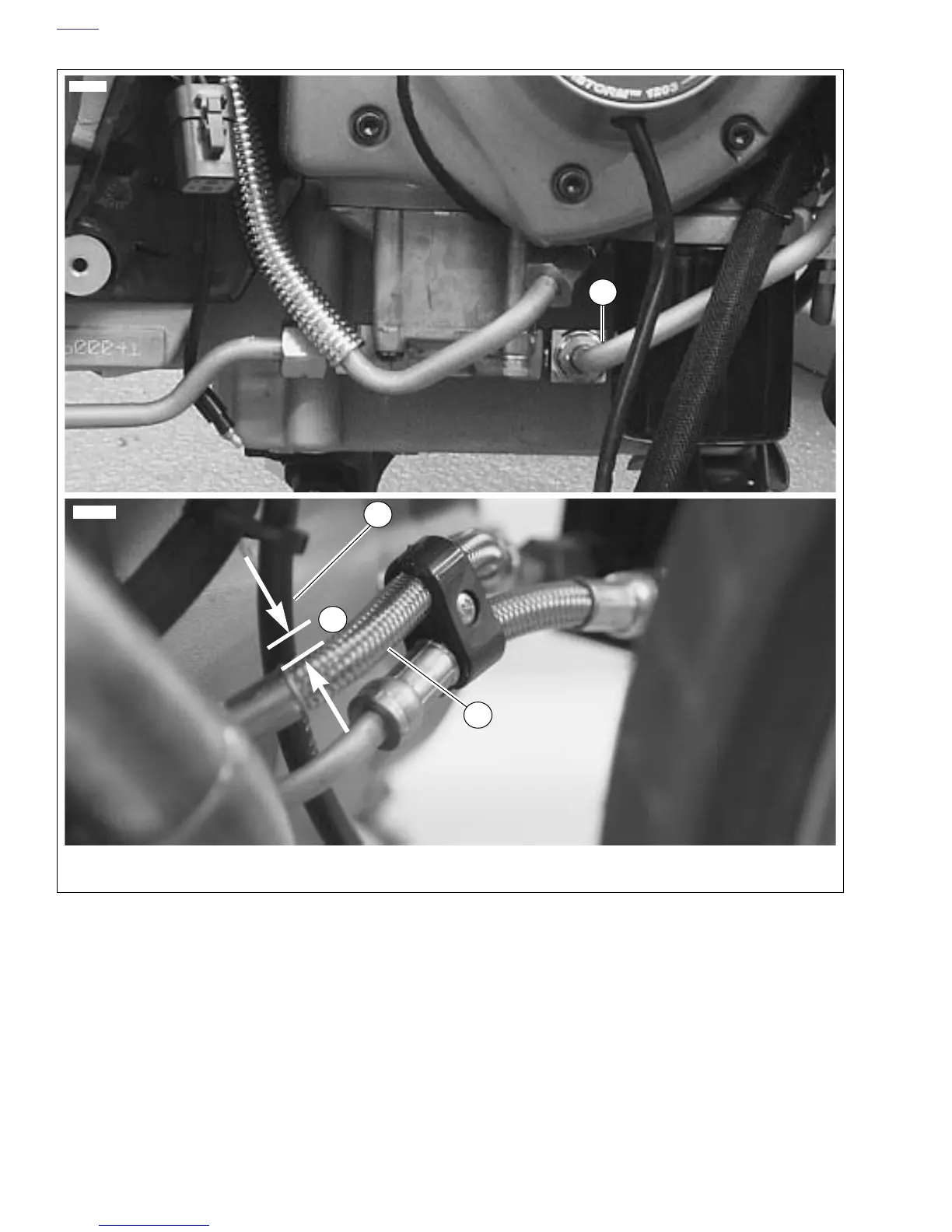

● See Figure 3-47. It is important to maintain an orientation

of approximately 2 o’clock with the rigid part of the feed

oil line running to the oil cooler. Also be aware of the 1/8-

1/4 (3.175-6.35 mm) clearance specified between the

feed oil line and the clutch cable at the front of the crank-

case.

● When tightening the oil cooler feed and return lines to oil

cooler, verify that the lines do not twist while tightening.

● If any oil line fittings are found to be loose, or not oriented

in the proper position, those fittings must be removed

and thoroughly cleaned. After cleaning, apply LOCTITE

565 Sealant to the fitting and re-install to the correct ori-

entation. When tightening oil lines, always support the oil

line fitting with a wrench to maintain proper orientation

and prevent damage to the oil line fitting.

Figure 3-47. Oil Cooler Feed Oil Line Orientation (Approximately 2 O’Clock) and Oil LIne Clearances

11971b

10501b

1.Clutch cable

2.1/8-1/4 in. (3.175-6.35 mm) clearance

3.Oil cooler feed oil line

4.Feed oil line to oil cooler orientation

1

2

3

4

Loading...

Loading...