The centrifugal force of a heavy spot on the rotor that causes the

rotor to vibrate increases with the square of the rotational speed. The

vibration level of the rotor may be acceptable at one speed but not at

another. Therefore, it is important to always allow the rotor to settle

to its normal operating speed before taking balancing analysis

measurements.

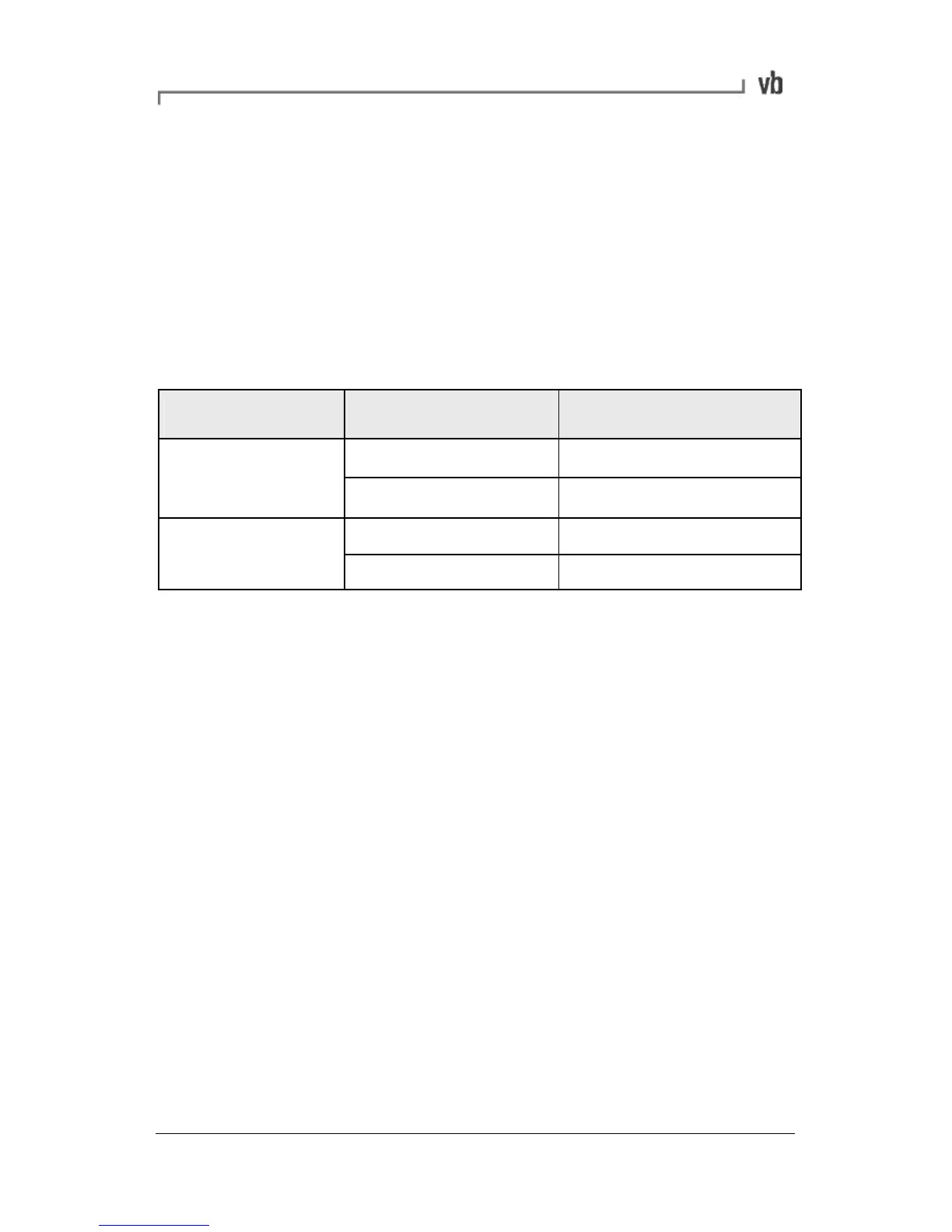

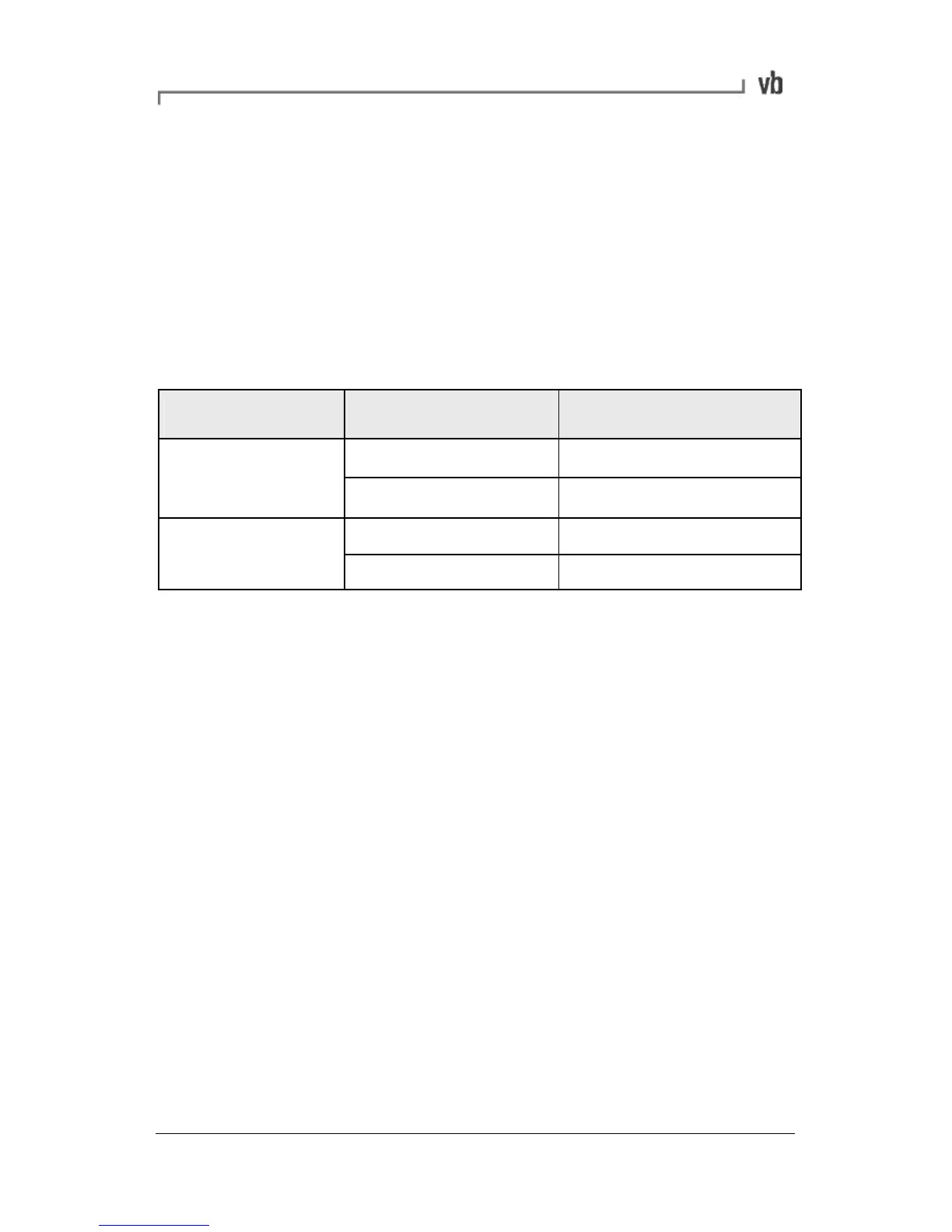

Whether a rotor should be balanced in one plane or two planes

depends on the dimensions and operating speed of the rotor. The

following guideline is commonly used:

Rotor Length to

Diameter Ratio

Operating Speed Balancing Technique

0.5 or less

1000 RPM or less Single plane balancing

More than 1000 RPM

Dual plane balancing

More than 0.5

150 RPM or less Single plane balancing

More than 150 RPM Dual plane balancing

Note: Before attempting to balance a rotor you must confirm that the

cause of vibration is uneven mass distribution in the rotor. Good

balancing results can be obtained only if vibration is caused by

uneven rotor mass distribution. Attempting to balance a rotor with

other problems will not, in general, reduce the vibration level.

The Balancing Process

A rigid rotor can be balanced in one or two planes. The following

steps are involved:

Setting Balancing Parameters - Select the units and balancing

method.

Initial Reading - Measure the initial imbalance.

Trial Reading - Attach a trial weight to the balancing plane and take

another measurement. For dual plane balancing, the same is also

done for the second plane.

Balancing - Attach correction weights to the balancing plane(s) as

recommended by the instrument.

Loading...

Loading...