6159930310_07_01/2016- 16 -

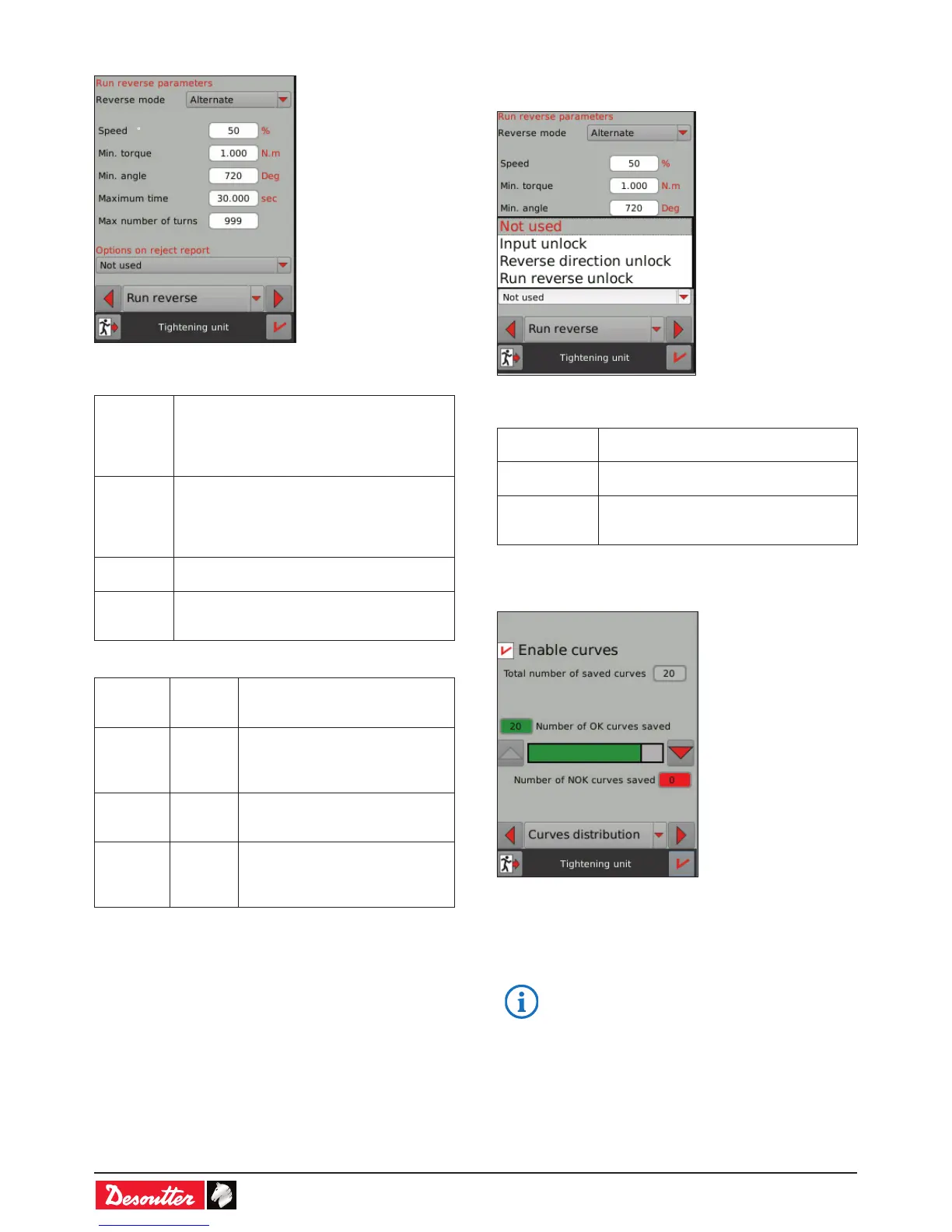

4.2 - Run reverse parameters

• Select the «Reverse mode» to reverse the tool direction

before starting.

Reverse

once

Pushing the reverse button, the reverse

direction is selected; the tool starts in reverse

direction when the operator presses the start

trigger. Once the tool has run, the tightening

direction is automatically re-activated.

Alternate Pushing the reverse button, the reverse

direction is selected. The tool starts in reverse

direction when the operator presses the start

trigger. Pushing again the reverse button, the

tightening direction is selected.

Reverse

disabled

The reverse direction is not possible.

Double hit • Quickly press the reverse button twice in

order to switch from the tightening direction

to the reverse direction (and vice versa).

• Fill in the following values:

Speed % or rpm

of max.

tool speed

This can be used for any run

reverse operation (except for a

Pset loosening step).

Min. torque

and Min.

Angle

Nm

Deg

These will allow to detect a real

loosening of the assembly. The

"Fastener loosened" output event is

activated.

Maximum

time

s Maximum loosening duration. The

tool stops automatically after this

time.

Max.

number of

turns

0-999 Maximum loosening turns from

trigger start. The tool will stop

automatically when this number is

reached.

4.3 - Options on «Reject report»

This option will prevent the operator from performing another

tightening operation after a NOK report.

• Select one of these options to unlock the tool and allow the

operator to do tightenings again.

Input unlock

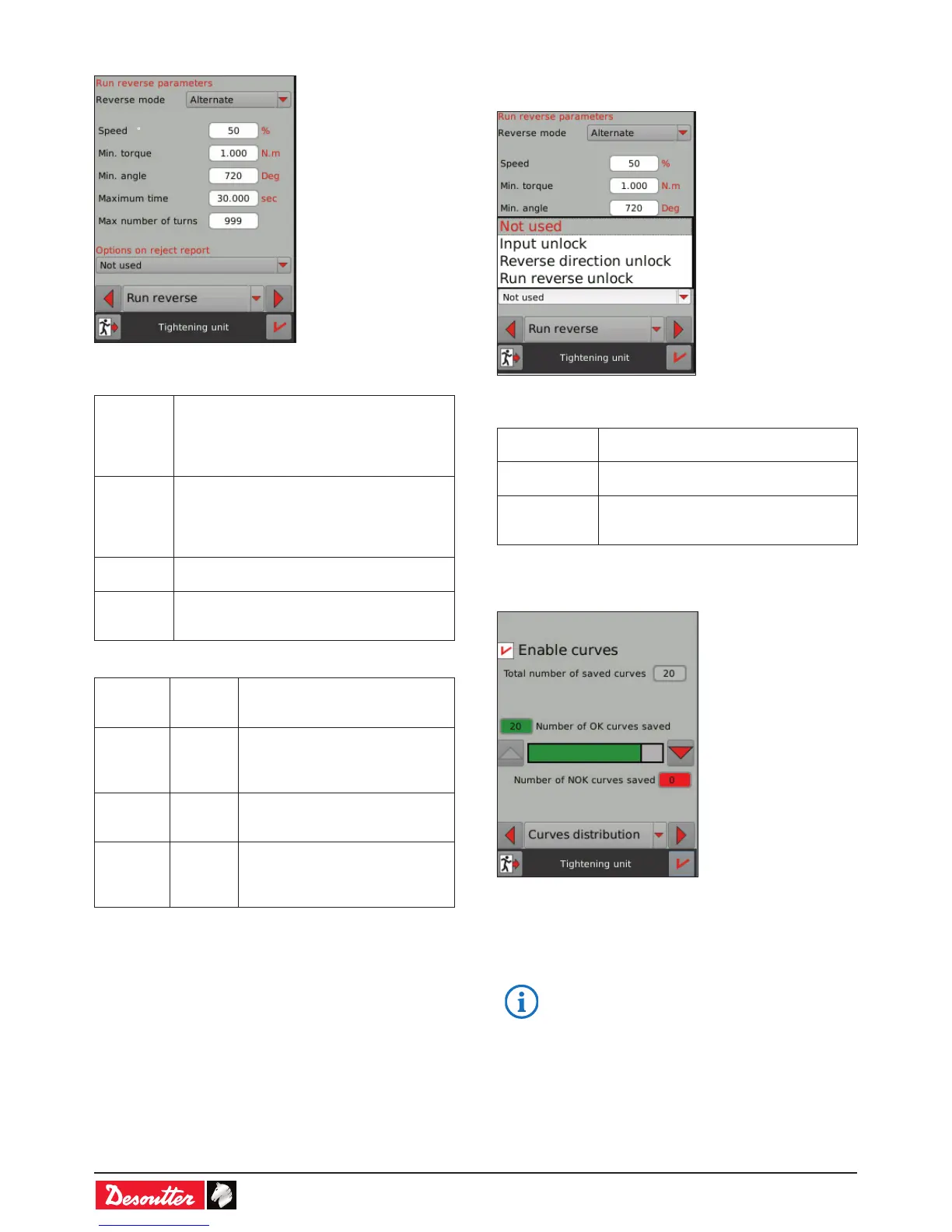

4.4 - Curves distribution

• Select your own curve distribution by sliding the cursor.

The maximum number of curves displayed depends on the

model of ePOD connected.

• Tick the box to enable or disable the curves generation.

• To select the number of points to store in

the curves (2,000 by default or 500 points),

launch "CVI CONFIG" software and go into the

conguration of the tightening unit.

Loading...

Loading...