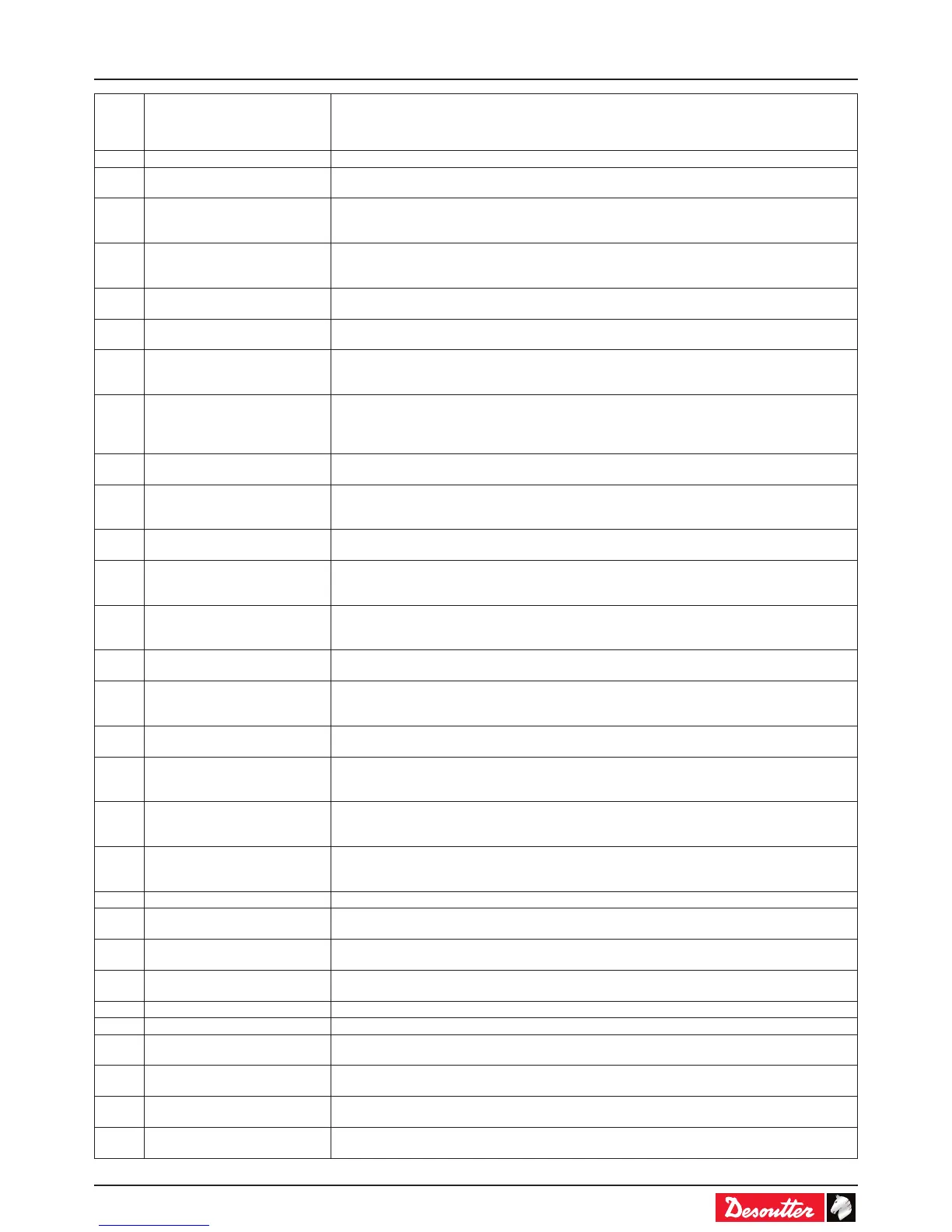

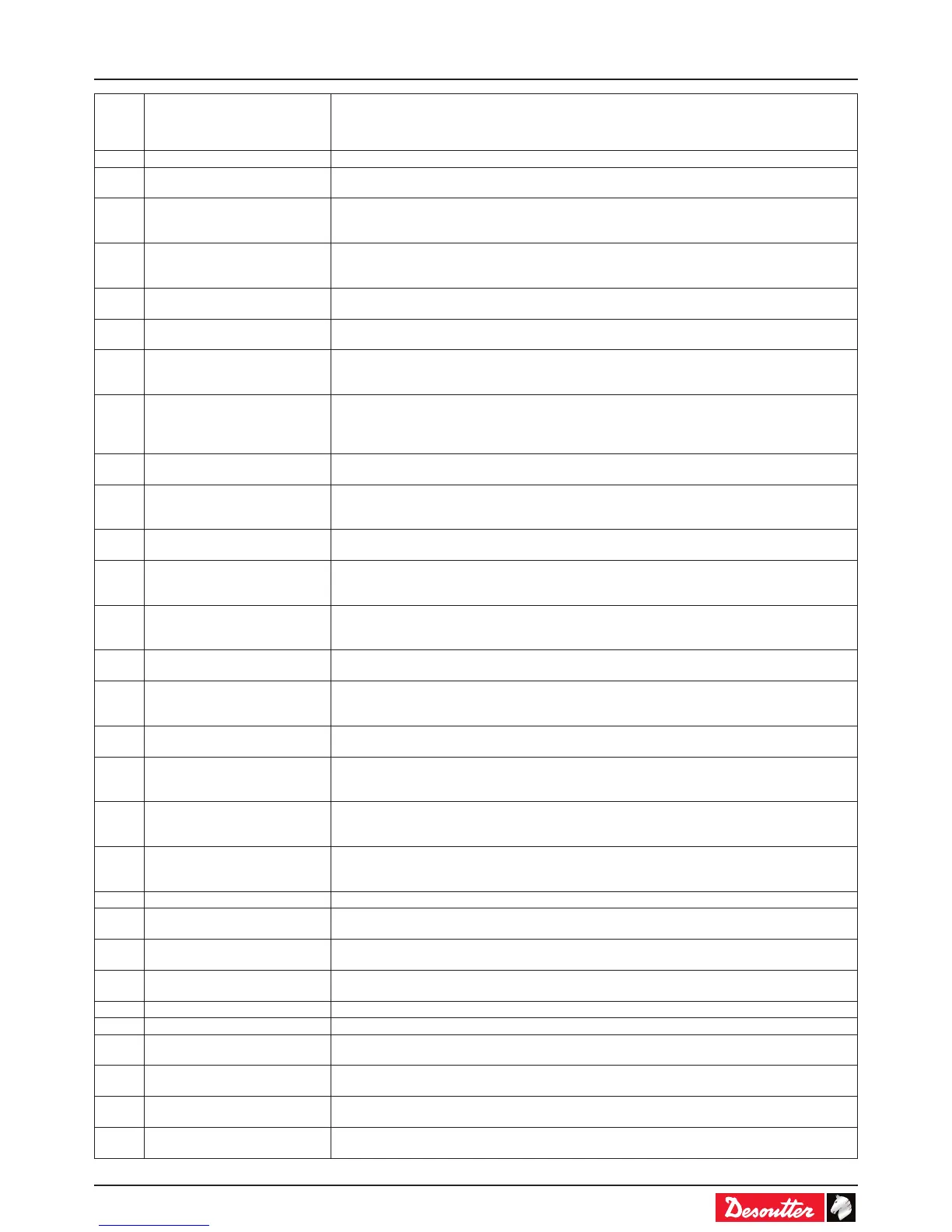

Appendix - User info codes_01/2016 - 63 -

Code

no.

Description Resolution procedure

2 Tool connected 1- The tool is connected and correctly recognized by the controller.

3 No tool connected 1- Tool has been disconnected.

2- If the tool is not physically disconnected, check the tool cable.

4 Span failure 1- Span value from torque sensor is outside bounds.

2 -Try once again to start the tool with no mechanical constraints. If the problem occurs again,

contact your Desoutter representative for support

5 Offset failure 1- Offset value from torque sensor is outside bounds.

2- Try once again to start the tool with no mechanical constraints. If the problem occurs again,

contact your Desoutter representative for support.

6 Tool motor rotor locked 1-Unable to start tool motor (rotor is locked), change your tool

2-Contact your Desoutter representative for support

7 Tool motor too hot 1- Tool is locked because its maximum motor temperature has been reached.

2- Tool will remain locked until the motor temperature comes back to its normal value.

8 Tool angle fault 1- Problem detected with the tool angle sensor

2- The tool needs maintenance.

3- Contact your Desoutter representative for support

9 Tool invalid parameters 1- Please check the tool compatiblity.

2- The tool memory cannot be read or is invalid.

3- The tool needs maintenance. If the problem occurs again, contact your Desoutter representative

for support.

10 Tool calibration alarm date expired 1- The tool calibration date has expired.

2- A tool calibration procedure needs to be done to ensure the measurement accuracy.

12 Tool EEPROM could not be read 1- The tool memory cannot be read or is invalid.

2- The tool needs maintenance. If the problem occurs again, contact your Desoutter representative

for support.

13 Tool motor bad ground connection 1- Phase-phase or phase to ground shortcircuit.

2- Disconnect the tool. Contact your Desoutter representative for support.

14 Tool torque power default 1- The torque sensor is not corrrectly supplied

2- The tool needs maintenance. If the problem occurs again, contact your Desoutter representative

for support.

15 Tool locked on reject 1- The tool is locked forward after a NOK.

2- Unlock the tool in function of the "lock on reject option" selection i.e. by reversing, loosening or

input.

16 Tool locked by Open Protocol 1- Tool has been locked by Open Protocol

2- Unlock the tool by sending an Enable tool message via Open Protocol

17 Loosening prohibited 1- Loosening is prohibited

2- The loosening is disabled in the Assembly action

3- The batch count type OK + NOK is used

18 Tool torque out of range 1- The target torque value is above the tool max. torque.

2- Check Pset settings against tool characteristics.

19 Tool communication error 1- Tool communication error.

2- Check tool and cable connections. If the problem occurs again, contact your Desoutter

representative for support.

20 Tool LED over current 1-Tool LED are not corrrectly supplied

2- Disconnect and reconnect the tool. If the problem occurs again, contact your Desoutter

representative for support.

21 Number of retries reached 1- The number of retries max has been reached.

2- The tool is locked.

3- The running Assembly Process has to be aborted.

22 Tool locked, lift correct socket 1- The tool is locked. Put all sockets back and lift the correct socket(s) combination.

23 Unsupported tool 1- The tool connected to the controller is not supported.

2- Contact your Desoutter representative for more information.

24 Tool loosening prohibited by VW

XML

1- Loosening is disabled by VWXML protocol

25 Tool tightening prohibited by VW

XML

1- Tightening is prohibited by VWXML protocol

26 Tool maintenance alarm 1 1- Tool maintenance tightening counter has been reached

27 Tool maintenance alarm number 2 1- Tool maintenance tightening counter has been reached

28 CVI3 and ExBC SW versions

incompatible

1 - Battery tool version and controller version are not compatible.

29 The battery is empty 1- The battery is discharged. The tool cannot tighten.

2- Recharge the battery.

30 The battery is low 1- The battery is low.

2- Recharge the battery.

31 Battery error 1- Abnormal battery voltage, the tool cannot tighten.

2- Recharge the battery. If the problem occurs again, replace the battery.

APPENDIX - USER INFO CODES

Loading...

Loading...