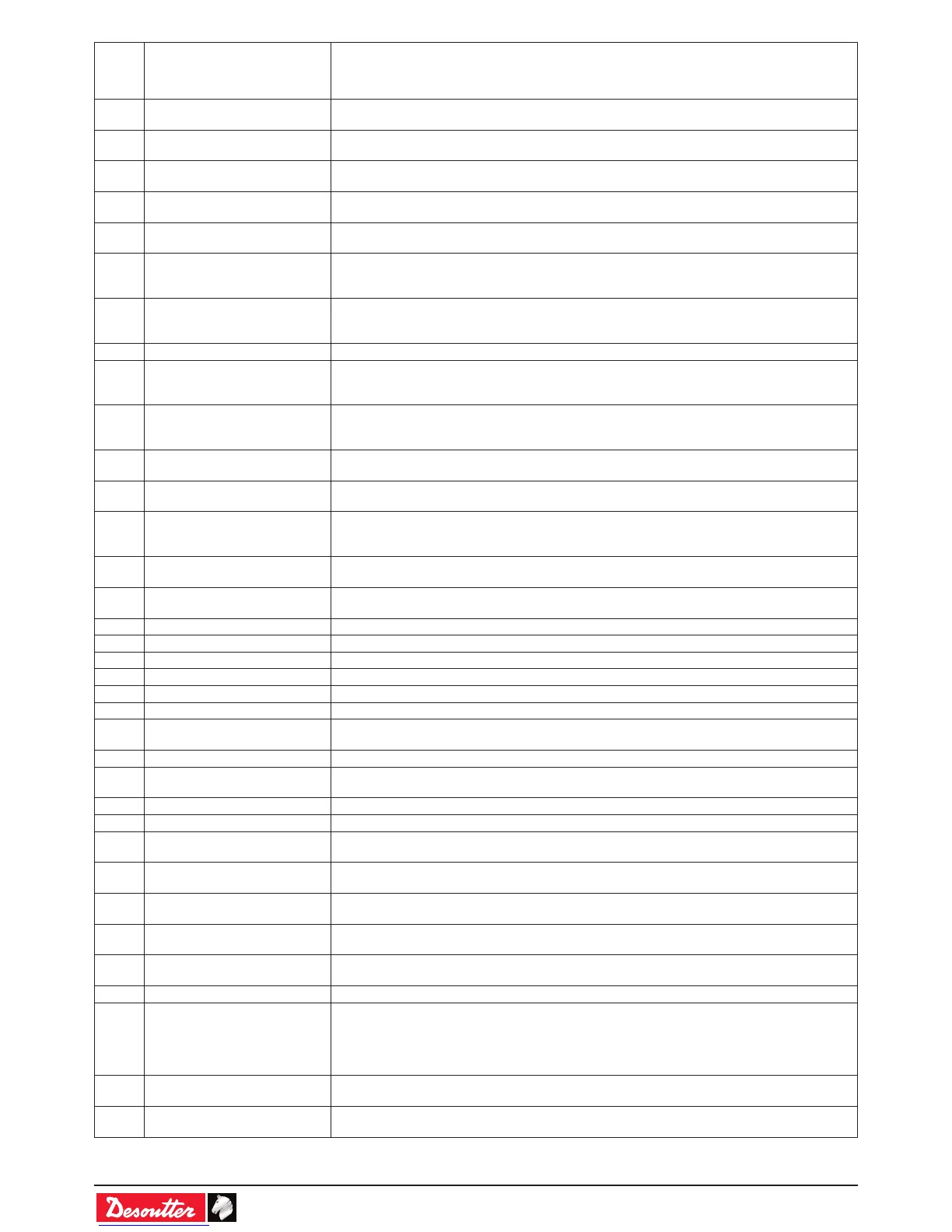

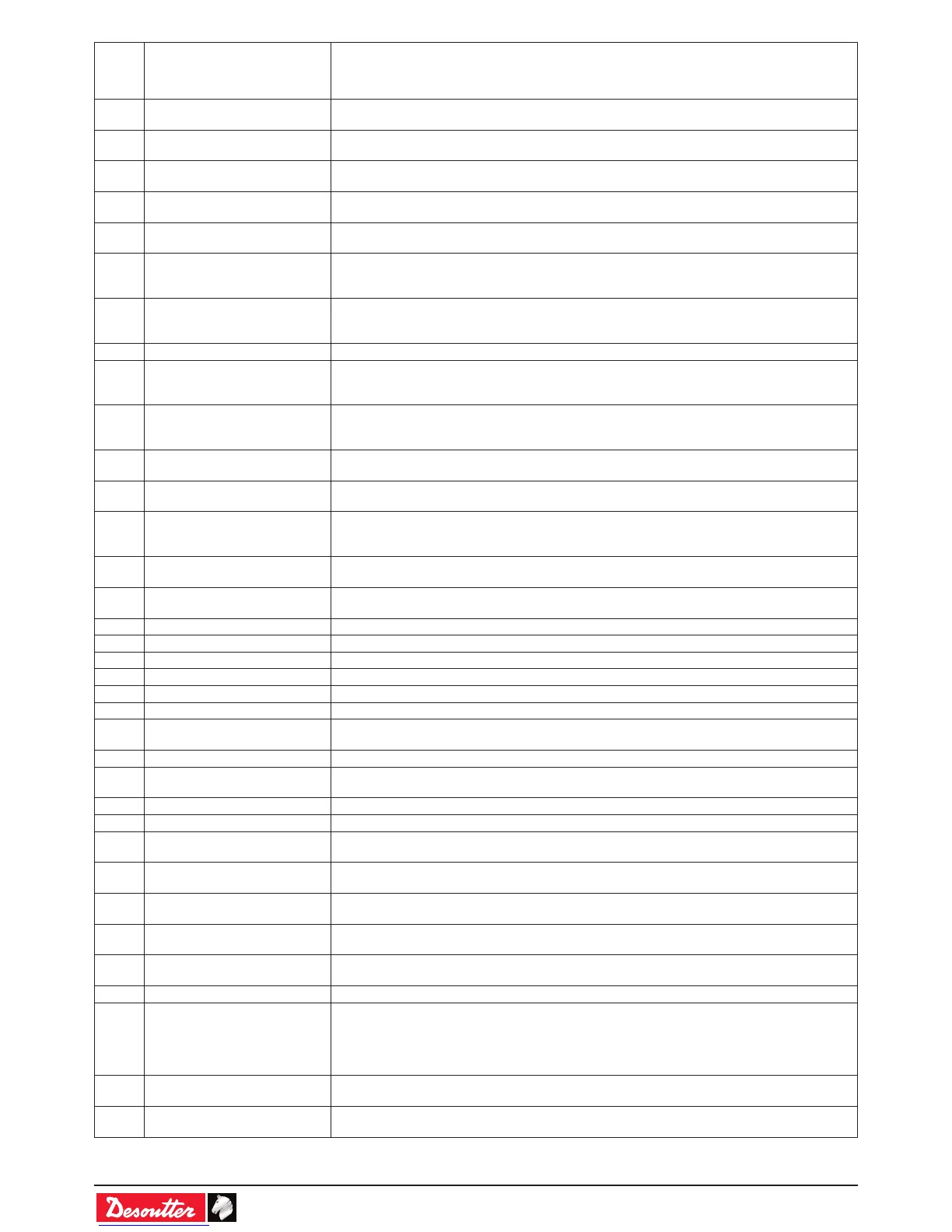

Appendix - User info codes _01/2016- 64 -

Code

no.

Description Resolution procedure

32 Tool display error 1- Board display malfunction.

2- Contact your Desoutter representative for support.

33 Tool time error 1- The tool time is not set correctly. The tightening results will not be time stamped.

2- Connect the tool to the controller to set date and time.

34 Tool memory error 1- The tool memory does not work properly.

2- Contact your Desoutter representative for support.

35 Tool memory locked 1- The tool memory is locked to protect old data from rewriting.

2- Connect the tool to E-dock to retrieve old data.

36 Tool memory full 1- The tool memory is full.

2- Connect the tool to the controller to empty the memory.

37 Tool trigger error 1- The tool trigger does not work properly.

2- Check and clean the trigger. If the problem occurs again, contact your Desoutter representative

for support.

38 Tool logs are available 1- Unexpected tool software exception

2- Log le has been generated by the tool

3-Contact your Desoutter representative for support

39 Tightening Unit cong error 1- Tightening Unit settings are invalid

40 Tool over speed 1- Motor speed exceeds 130% of its maximum value.

2- Check tool parameters.

3- Wrong motortune parameters. Contact your Desoutter representative for support.

41 The tool is unauthorized 1- The tool connected to the controller is not authorized.

2 Maximum number of battery tool reached or tightening unit associated doesn't exist anymore

3- Check the ePOD connection and capacity.

42 Tool locked by GeoPositioning 1- Tool has been locked by GeoPositioning

2- Unlock the tool by moving the tool in its dened area

45 Anormal battery high voltage,

check your battery

1- Anormal battery high voltage, check your battery.

2- This error can due to charger malfunction or end of life battery.

46 Anormal battery current

consumption, check your PSet

settings

1- Anormal battery current consumption, check your PSet settings.

2- This error can due to speed settings.

47 Battery is too low, check your

battery

1- Battery is too low, check your battery.

2- If the problem occured again, change the battery with a new one.

48 Battery type not allowed 1- Battery type not allowed.

2- Change your battery type or your conguration.

49 Access denied on controller Access denied on controller

50 Incompatible network parameters Incompatible network parameters

51 Epod connected Epod connected

52 Incorrect network parameters Incorrect network parameters

53 No TU available No TU available

54 Pairing success Pairing success

55 EDock already present on

controller

EDock already present on controller

56 Epod disconnected Epod disconnected

58 Tool locked by GeoTracking 1- Tool has been locked by GeoTracking

2- Unlock the tool by moving the tool in its dened are

59 New tool detected No procedure

60 Tool synchro ongoing No procedure

100 Tool cable id invalid parameters 1- Invalid tool cable parameter, check that the tool cable is Desoutter certied

2- Contact your Desoutter representative for support

101 Tool cable id not detected 1- Tool cable communication error, check that the tool cable is Desoutter certied

2- Contact your Desoutter representative for support

102 Tool cable id not certied 1- Tool cable authentication error, check that the tool cable is Desoutter certied

2- Contact your Desoutter representative for support

199 Serial console activated 1- The serial console is activated.

2- Warning, this console is dedicated only to debug purposes and should not be used in production

200 Quick stop activated 1- The quick stop has been activated

2- Check the Phoenix connector

201 Replace backup battery 1- The real time clock backup battery needs to be replaced.

202 Fieldbus connection lost 1- Fieldbus connection with PLC is lost.

- no heartbeat is received from PLC

- the cable is broken or disconnected

- the PLC is off line or not powered

2- Check the Fieldbus conguration.

204 Tool not validated by IO 1- Tool locked by I/O.

2- Check the I/O settings: the "Tool validation" must be active to unlock the tool.

205 Torque settings and tool mismatch 1-Invalid Torque setting, torque is greater than tool characteristics

2-Check Pset settings with the current tool characteristics

Loading...

Loading...