6159930310_07_01/2016 - 31 -

7.5.4 - Latch threshold

The controller starts measuring the angle when the torque

crosses the angle threshold for the rst time.

When this option is ticked, the measure then continues till

the end even if the torque becomes below the threshold. The

measured angle is therefore closed to the real angle.

When this option is not ticked, the controller stops counting

the angle when the torque falls below Angle threshold.

Target angle

Angle with

latched threshold

Angle without

latched threshold

Angle threshold

(Sec.)

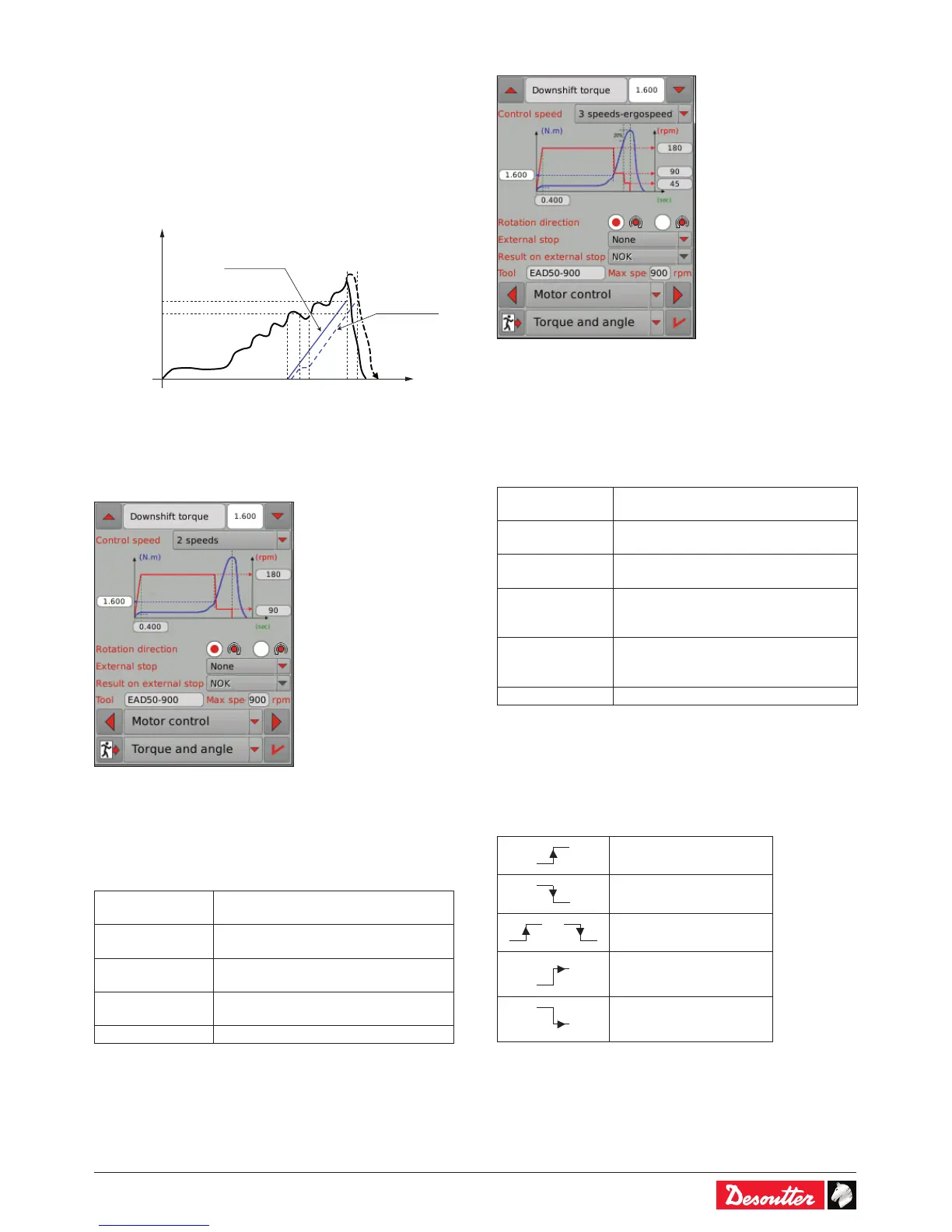

7.6 - Motor control

7.6.1 - 2 speed

Starting at the start signal, the tool runs with a programmed

acceleration up to Rundown speed. The tool keeps running at

Rundown speed. Once Downshift torque has been reached,

the speed changes to Downshift speed.

Parameters

Time to increase speed from 0 to

Rundown speed.

Speed applied from start to downshift

torque to optimize productivity

Torque where speed moves from

Rundown to Downshift speed.

Speed applied from Downshift torque to

motor stop to optimize quality.

Clockwise / Counterclockwise

7.6.2 - 3 speed - ergospeed

Starting at the start signal, the tool runs with a programmed

acceleration up to Rundown speed. The tool keeps running at

Rundown speed. Once Downshift torque has been reached,

the speed changes to Downshift speed. Once 80% of the

Target torque has been reached, the speed changes to Final

speed.

Parameters

Acceleration time

Time to increase speed from 0 to

Rundown speed.

Rundown speed

Speed applied from start to downshift

torque to optimize productivity

Downshift torque

Torque where speed moves from

Rundown to Downshift speed.

Downshift speed

Speed applied from Downshift torque

to the 2nd Downshift to break inertia or

very hard joints.

Final speed

Speed applied from the 2nd Downshift

(80% of Target torque) to motor stop (to

optimize quality on very hard joint).

Clockwise / Counterclockwise

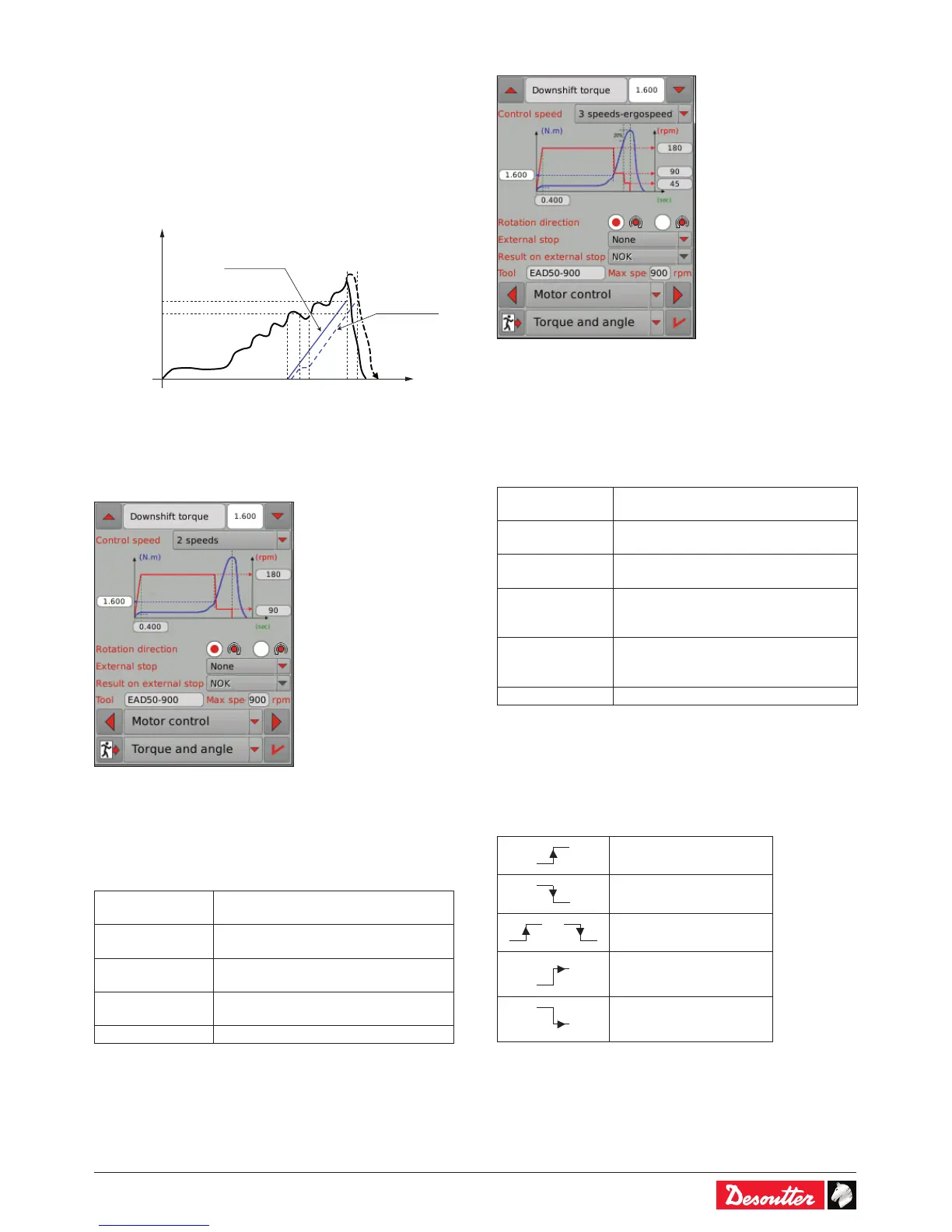

7.7 - External stop

• Select this input to stop the current step and skip to the

next one.

The conditions can be as follows:

The input event is: «External stop to next step».

on rising edge

on falling edge

/

on change (rising or

falling)

on high level

on low level

7.8 - Result on external stop

• If the «External stop to next step» event condition is

detected, the step report can be forced to OK/NOK or will

depend on the Monitoring.

Loading...

Loading...