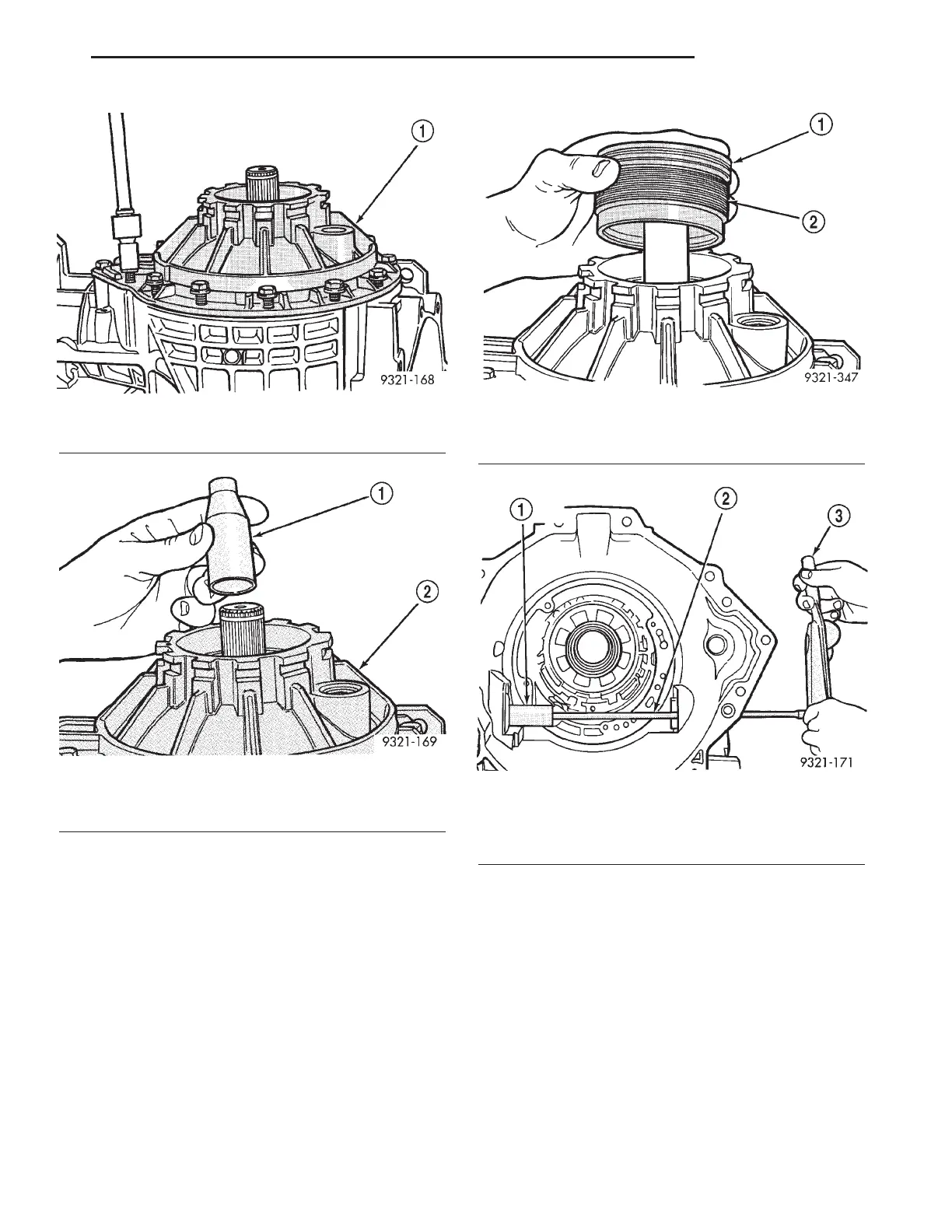

(28) Screw on outer adjuster and tighten adjuster

down finger tight (Fig. 211).

(29) Insert special tool 6548 (Fig. 212). This tool

will be used to check turning torque of the differen-

tial assembly.

CAUTION: Differential bearings must be seated

before taking turning torque readings. This is done

by rotating the differential three or four turns in

both directions.

CAUTION: Turning torque of 19 to 23 in. lbs. can

only be obtained when using new bearings. Do not

attempt to obtain this turning torque with used

bearings.

(30) Tighten outer adjuster with tool 6503 until 19

to 23 in. lbs. of turning torque is obtained on tool

6548. Record how many foot pounds were

required on the outer adjuster to obtain the

correct turning torque (Fig. 213). Record the foot

pound reading. The reading that you are recording

will be used in Step 54 of this procedure.

(31) Remove the differential cover, differential car-

rier assembly and inner adjuster.

(32) At this point the amount of torque required

on the outer differential adjuster has been deter-

mined. The transfer shaft can now be installed into

the transaxle case. Perform the following steps to

install transfer shaft into transaxle case.

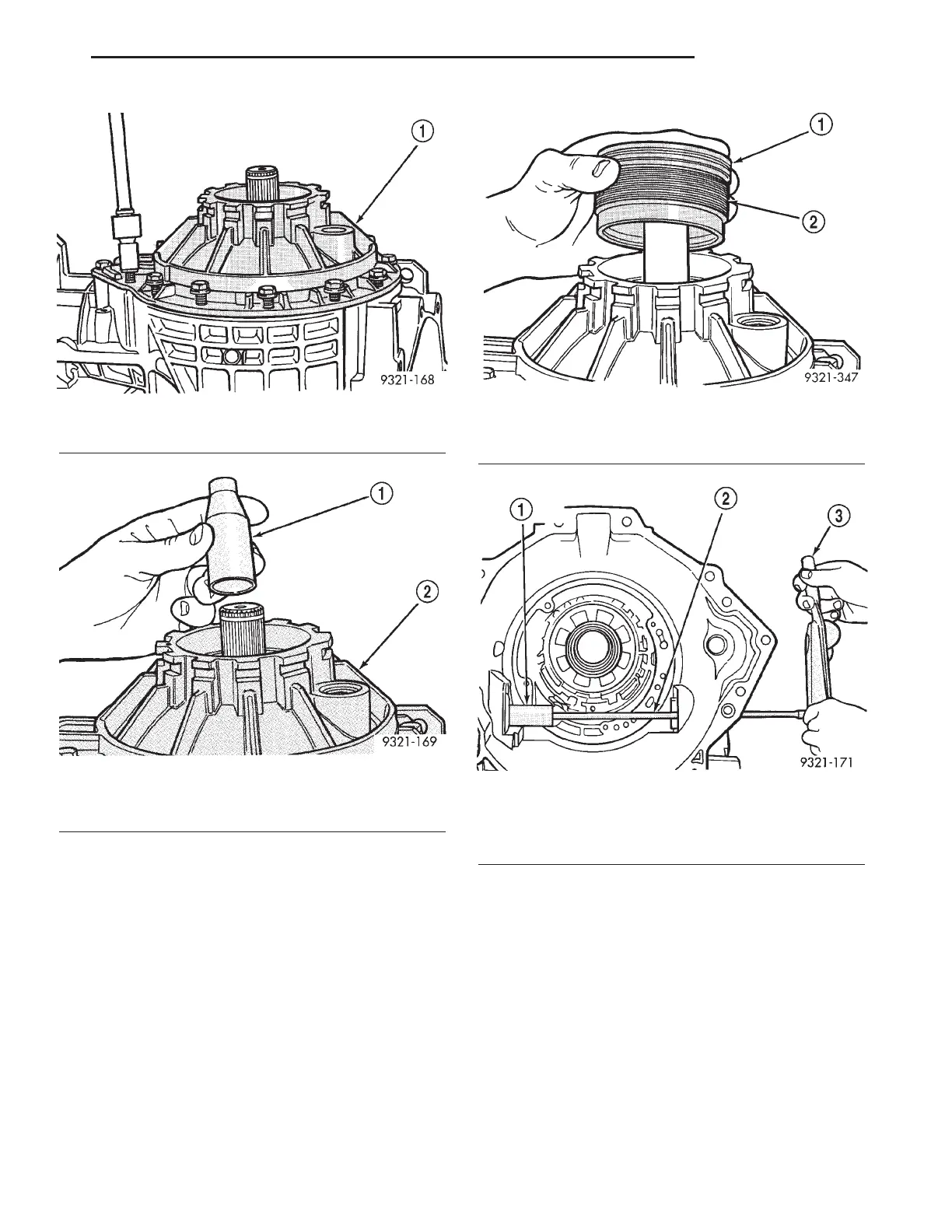

Fig. 209 Differential Cover Installation

1 - SIDE COVER

Fig. 210 Seal Protector

1 - SEAL PROTECTOR (6591)

2 - SIDE COVER

Fig. 211 Outer Adjuster Installation

1 - O-RING

2 - OUTER ADJUSTER

Fig. 212 Special Tool 6548

1 - SPECIAL TOOL 6548

2-

1

⁄

4

9 EXTENSION

3 - TORQUE WRENCH

LH TRANSAXLE 21 - 89

FINAL DRIVE (Continued)

Loading...

Loading...