STP-iXA3306 Series Turbomolecular Pump

The STP pump should be installed in an area which meets the following requirements:

0 to 40 °C (32 to 104 °F)

Ambient relative humidity

30 to 95% (no dew condensing)

An area free of externally applied mechanical shock.

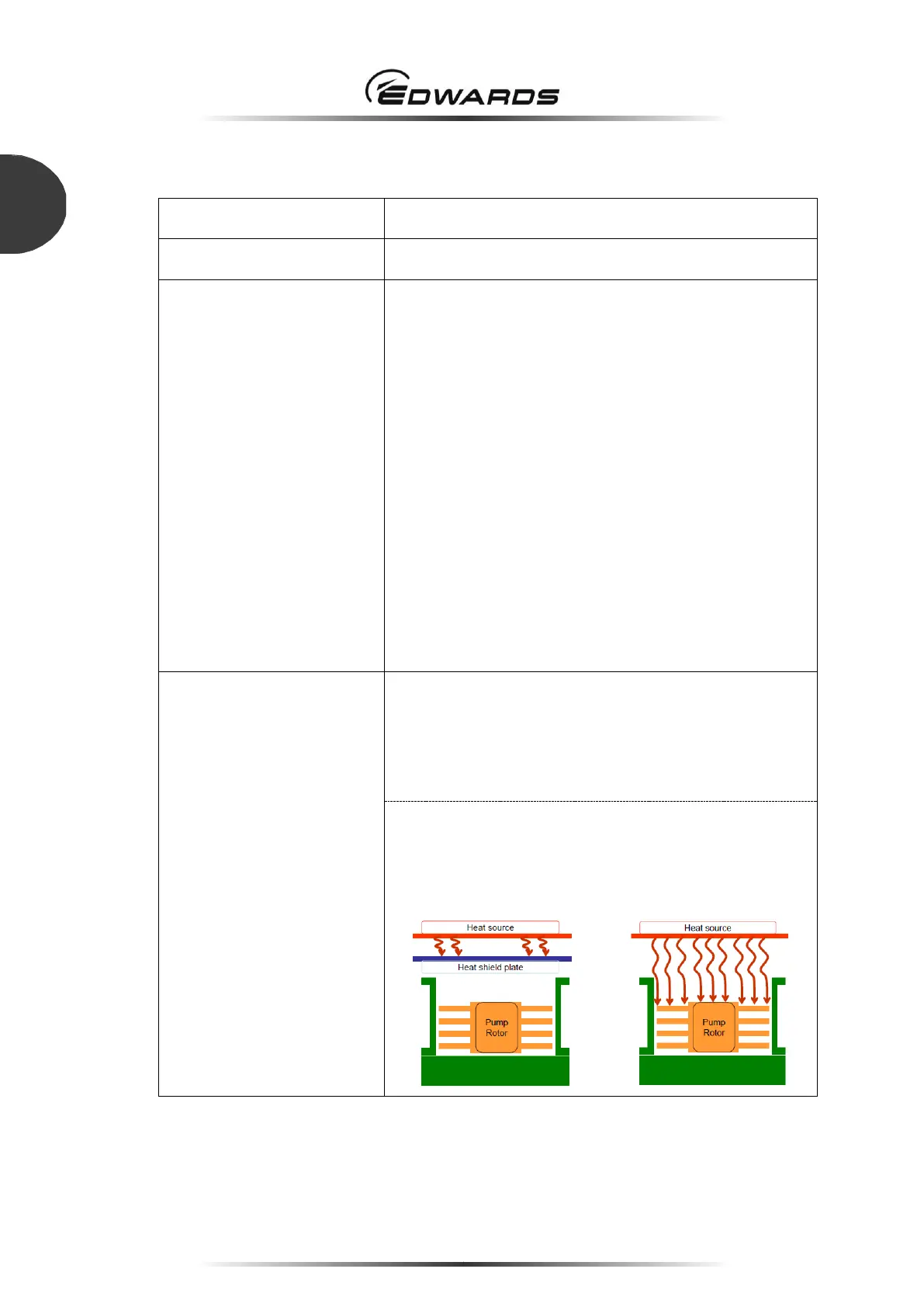

A place free of a heat source (Keep clear of the heat

source or attach a thermal shield plate).

A place free of a strong magnetic field (Range: up to 15

mT (150 G) in the axial direction, and up to 3 mT (30 G) in

the radial direction with respect to the rotational axis of the

STP pump).

A place free of a strong electric field.

A place free of exposure to radiation.

No discharge of high voltage (more than 500 V) (If more

than 500 V is discharged, contact Edwards).

Others: An area free of exposure to direct sunlight, high

humidity, dust, salty air, dripping water, explosive or

flammable gas, corrosive gas, excessive vibration and

sources of electric noise.

STP pump installation

equipment conditions

Install the STP pump securely so that foreign materials

cannot fall into the STP pump (Ex.: Si wafers or samples are

positioned above the STP pump) (To prevent foreign

materials from falling into the STP pump, design a shield

plate with large conductance).

Install the STP pump so that the inlet flange of the STP

pump not to be exposed to heat source. (Install the heat

shield plate so as to prevent the effect by radiation heat)

* STP-iXA3306 series is equivalent to the specification of Protection Classification IP54 sealed. This model has protection

against dust and water splashed from any direction. Refer to IEC60529-2001 for details.

Table 5 - Environmental requirements for installation

Loading...

Loading...