Revision 14

165 August 02, 2019

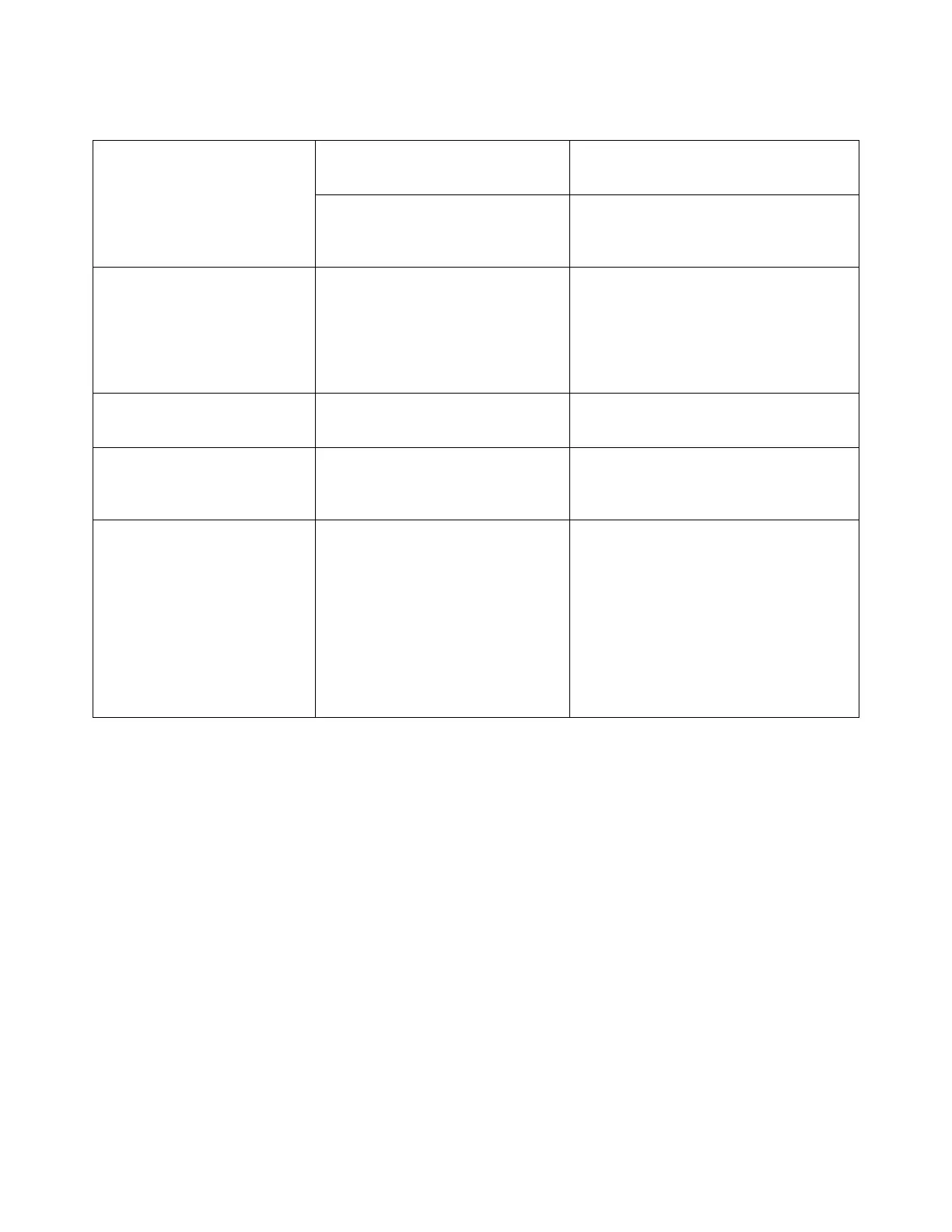

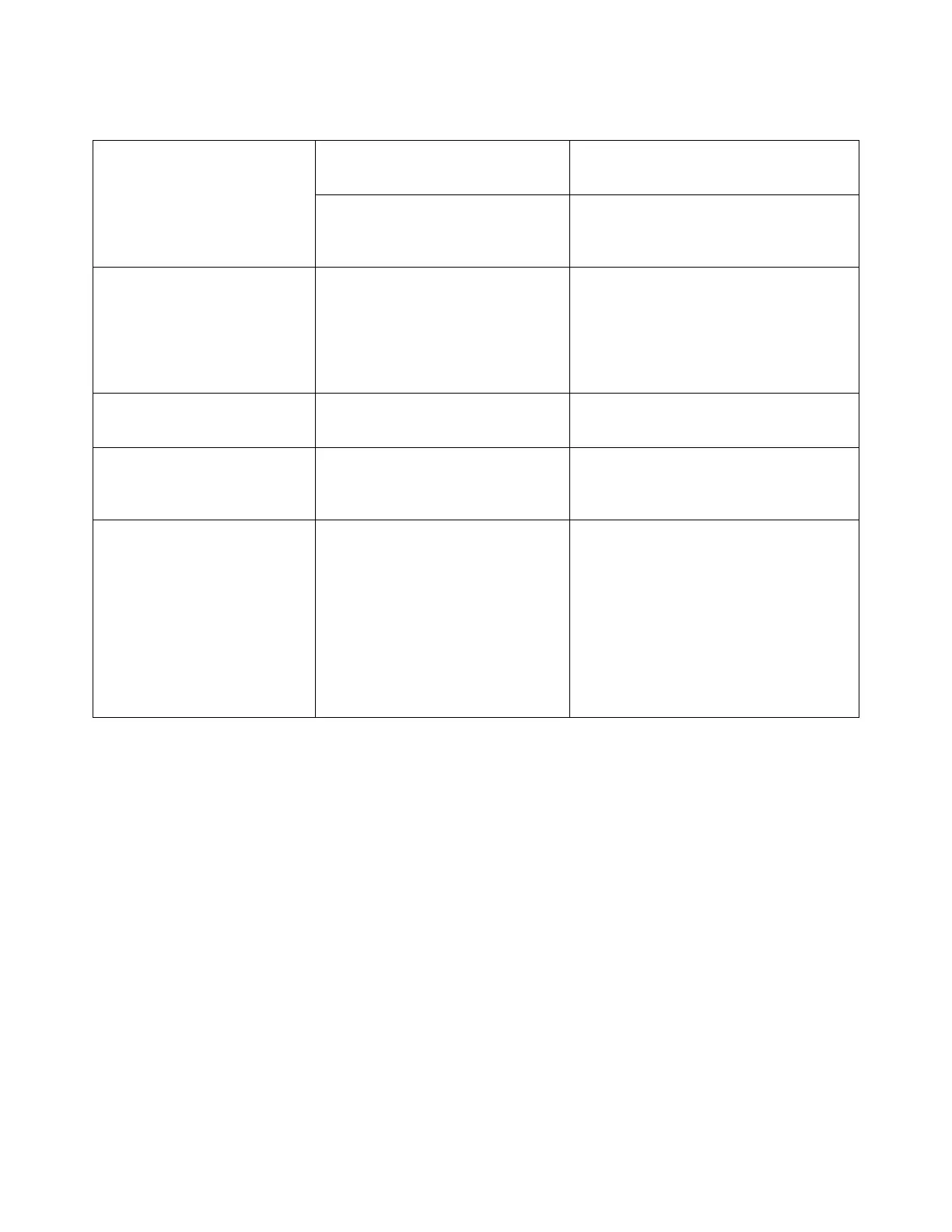

8. Stains unevenly spaced

(large gaps between stains).

This should be accompanied

by a Tape Movement alarm.

Optical Encoder not correctly

connected to sensor block.

Check that Optical Encoder connector

on the top right corner of the sensor

block is correctly connected.

Optical Encoder not rotating.

Check that the Optical Encoder

capstan is rotating when the tape

advances. If not, the Optical Encoder

9. Total Sulfur readings are

erratic.

Furnace is not hot enough

Increase value in the Furnace Pulse

Width field in the Global page of the

GUI. If the erratic readings are

accompanied by a Low Temperature

Alarm (FURN on Analyzer Alarm List),

the furnace element may

10. 4-20mA outputs not

agreeing with display on the

screen.

Ranges are not configured

correctly.

check the analog output range values

on the Output tab of the GUI

11. Calibration, Reference,

or zero runs are not running

after

being initiated by

keypad or schedule

ProTech903 is in Alarm 1 or PAA

condition on H

2

S Run

Wait until Alarm condition has cleared.

Calibration, reference, or zero run will

then automatically run in the order they

Alarm

Analyzer is out of tape

Sensor is not calibrated

Replace tape

Re-

calibrate the sensor with clean

white tape installed. Access SenCal on

the keypad. Press the EDIT key and

press ENTER key to toggle the

parameter to ON. The sensor will

calibrate and then automatically go

online

Loading...

Loading...