Revision 14

21 August 02, 2019

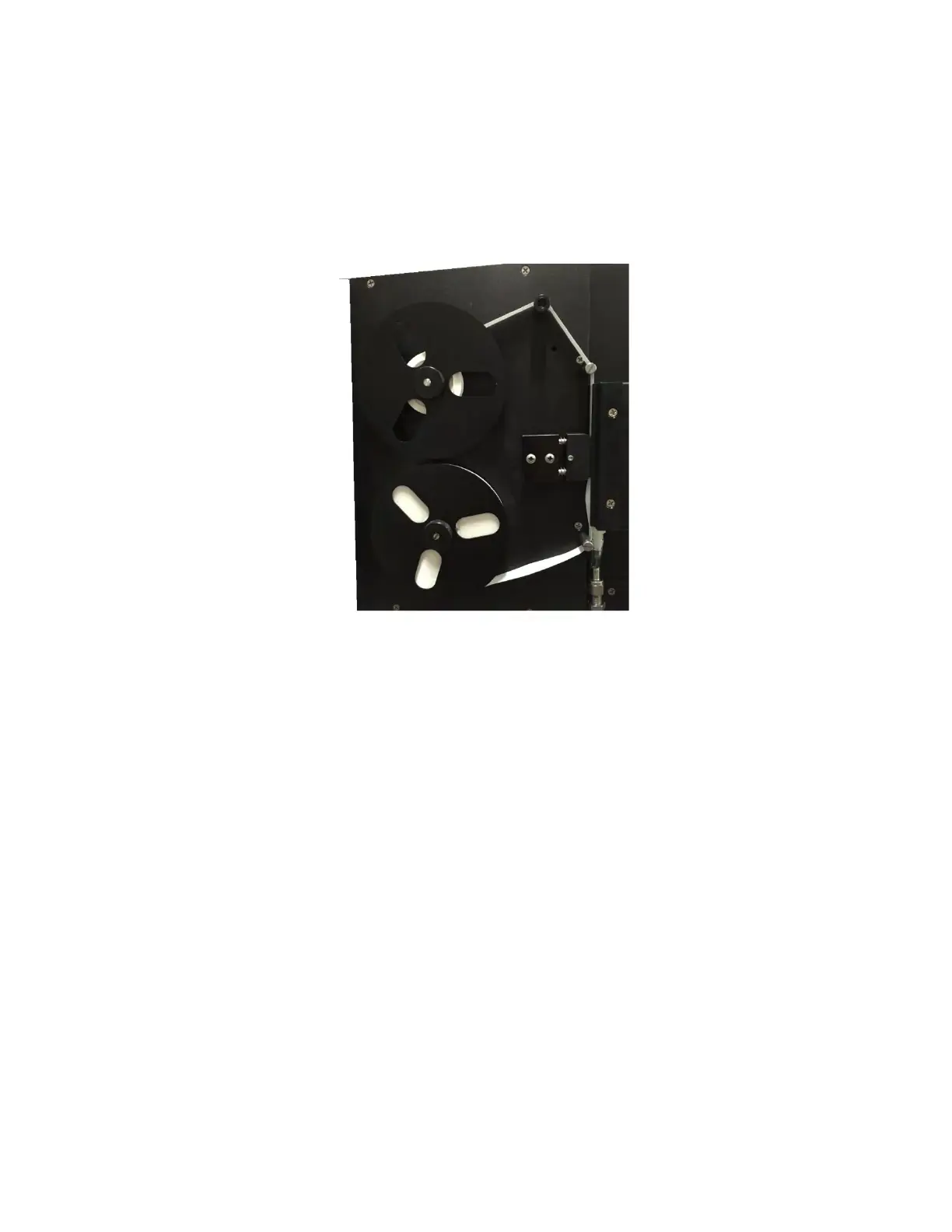

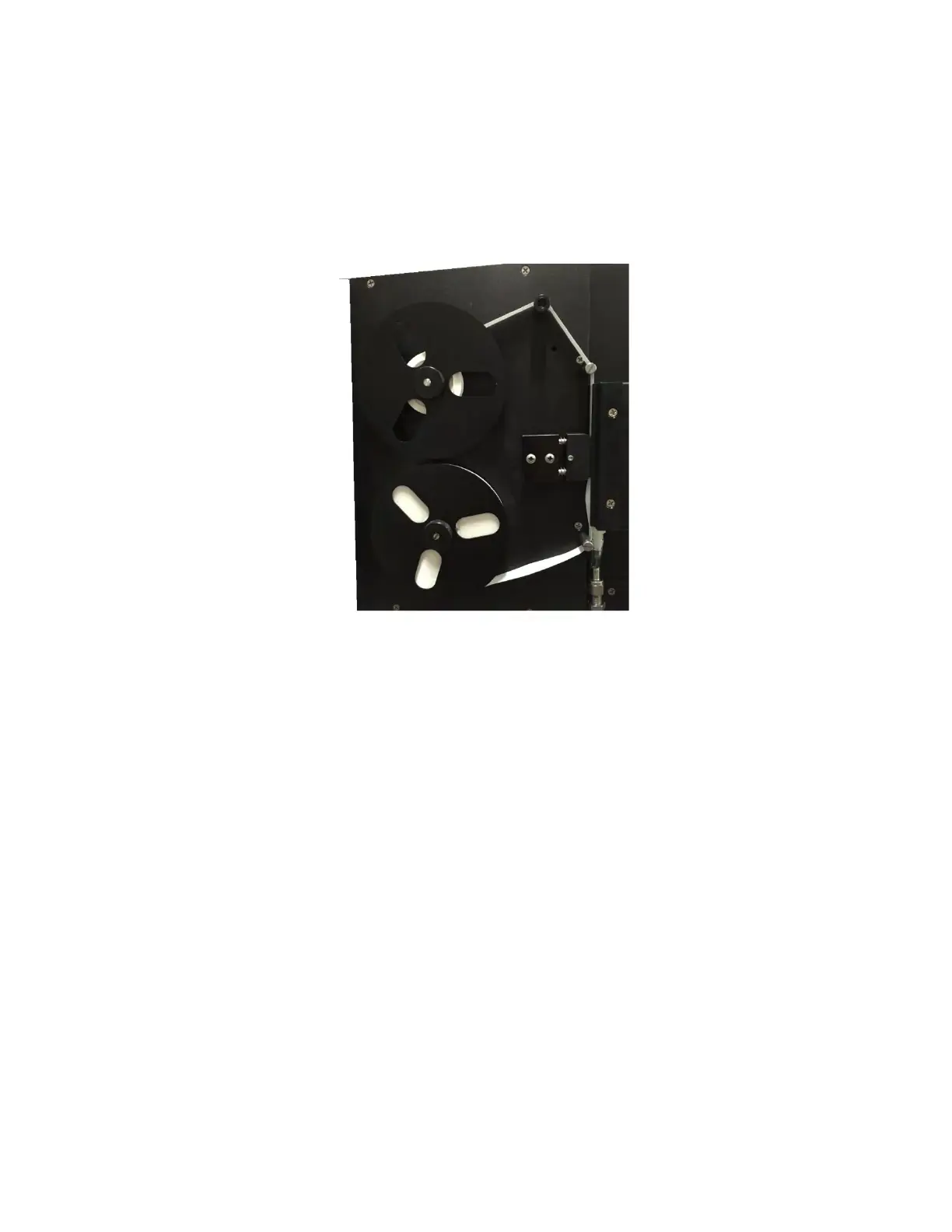

2.6 Tape Transport System

The tape transport system is responsible for advancing the tape and ensuring that the system

has a fresh section of white tape available at the commencement of every analysis cycle. The

tape transport system is shown in Figure 2-4.

Figure 2-4: Tape Transport System

The tape transport system consists of the supply and take-up reels, the drive motor, the

compression head, the Optical Encoder, and the optional low-tape sensor.

2.6.1 Supply and Take-up Reels

The supply and take-up reels are the key components in the tape transport system.

• The supply reel is found on the bottom of the chassis, and can hold reels of tape up to 350

feet in length. The tape is threaded over the lower tape guide, past the sample chamber

assembly and compression head, over the two upper tape guides, and finally over the

Optical Encoder pulley before reaching the take-up reel.

• The take-up reel is driven by the motor, and is responsible for advancing the tape at the end

of every cycle.

A small standard 5VDC electric motor that is controlled by the main processor of the system

turns the take-up reel to advance the tape at the beginning of every analysis cycle to ensure

that the next analysis has a section of pure white tape to react with the H

2

S.

The motor is either installed inside the chassis, in the Division 2 system, or in an explosion

proof enclosure on the outside of the chassis, in the Division 1 system. The length of time

that the motor runs is controlled by the system processor in conjunction with the Optical

Encoder.

Loading...

Loading...