Revision 14

51 August 02, 2019

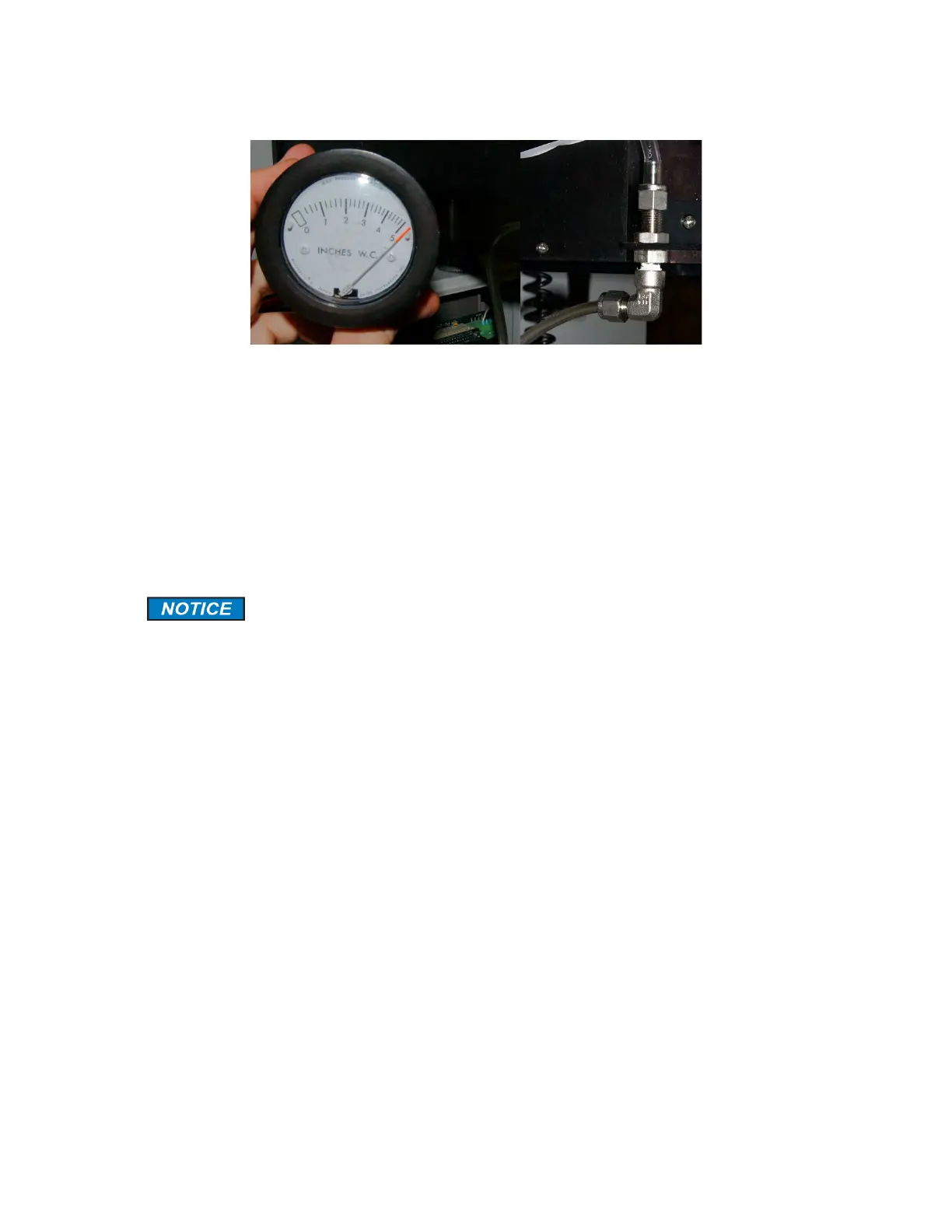

Figure 3-22: Minihelic Indicating a Good Seal (L); Connected to Vent Elbow (R)

d) Check the pressure indicated on the gauge. If the pressure reads 4 or above, as shown

in Figure 3-22, the tape is well sealed against the sample chamber by the compression

head. Press Tape Advance on the keypad and ensure that the pressure does not drop

below 3 even when the tape is moving. It should return to 4 by the time the tape stops

moving.

If the pressure is NOT 4 or greater, there is a problem with the seal somewhere in the

chassis.

3.7.3 Leak Testing the Total Sulfur Accessory

Connect the USB to USB cable from the laptop to the analyzer and log onto the

analyzer using the Galvanic GUI software. Go to the Global tab and turn off the power

to the furnace by setting the Furnace Pulse Width to 0 %. Perform a temporary write to

the analyzer and wait until the furnace housing is cool to the touch.

test the furnace for leaks as described below:

a) Turn the hydrogen flow on. Ensure hydrogen is flowing at 2.0 and sample is flowing at 1.0

on the rotameters.

b) Place a ¼ inch cap on the top of the furnace output flame arrestor as shown in Figure 3-

24. This will block flow through the total sulfur furnace.

Loading...

Loading...