Revision 14

30 August 02, 2019

2.9 Total Sulfur Option

The system is available with an oven that converts sulfur compounds to H

2

S, so that the total

sulfur content of a sample gas stream can be determined. With a dual stream setup, it is

possible to measure both the H

2

S and the total sulfur content of the same stream on the

same system.

The sample gas is mixed with hydrogen in a quartz reaction tube at a temperature of 900°C.

At this temperature, the hydrogen reacts with all sulfur components to form H

2

S, and most

hydrocarbons to form methane. The conversion of total sulfur to hydrogen sulfide is covered

in ASTM Method D4468-85: Total Sulfur in Gaseous Fuels by Hydrogenolysis and

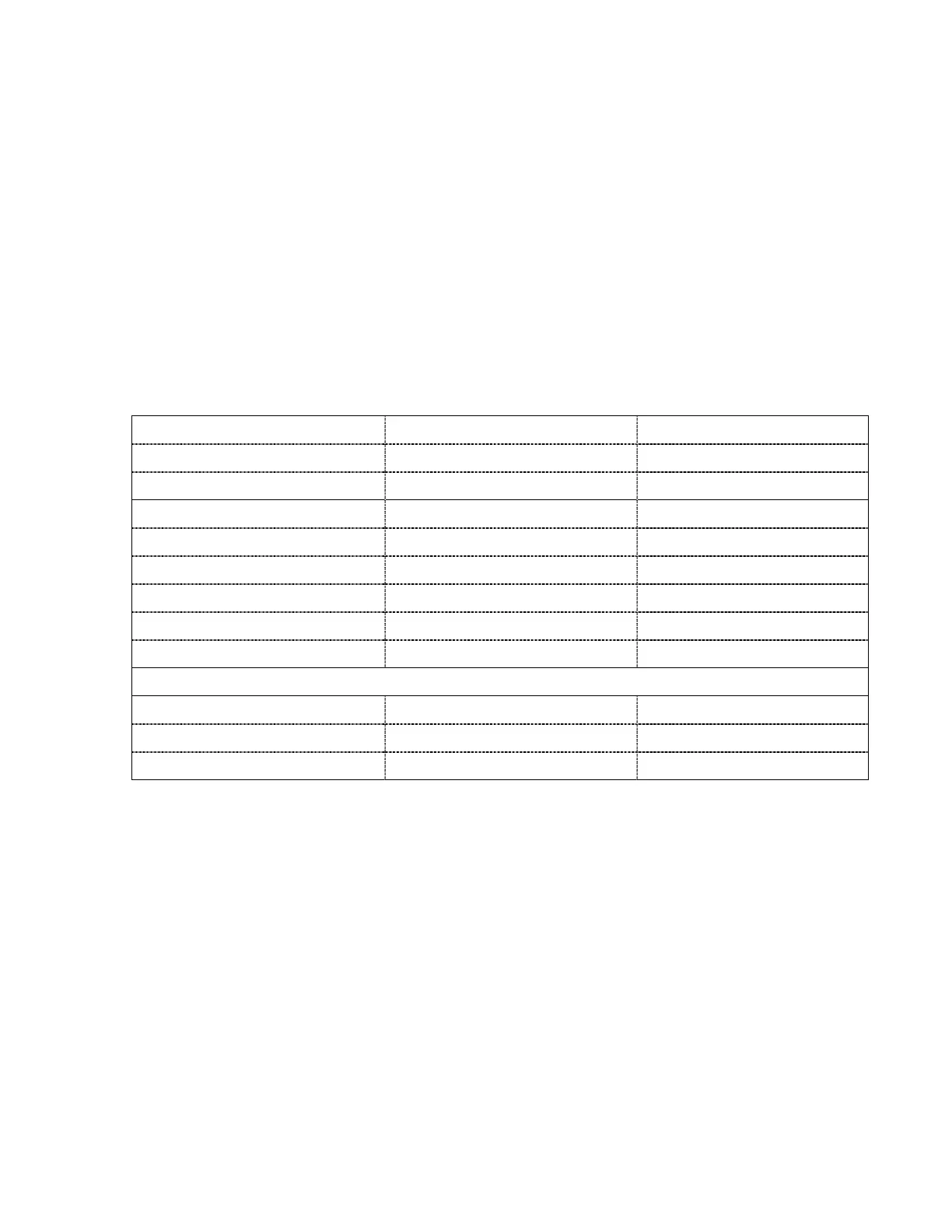

Rateometric Colorimetry. A few typical reactions are shown in Table 2-2.

Table 2-2: Total Sulfur Reactions

Carbonyl Sulfide

COS + 4H

2

H

2

S + CH

4

+ H

2

O

900°C

Ethyl Sulfide

(C

2

H

5

)

2

S + 4H

2

H

2

S + 4CH

4

900°C

Methyl Sulfide

(CH

3

)

2

S + 2H

2

H

2

S + 2CH

4

900°C

Example of cracking:

Butane

C

4

H

10

+ 3H

2

4CH

4

900°C

Because the sulfur compounds are converted into hydrogen sulfide, a measurement of the

hydrogen sulfide content formed by these reactions will be directly equivalent to the total

sulfur content in the sample gas stream.

The formation of H

2

S takes place in an external total sulfur furnace that is mounted below the

electronics enclosure. The total sulfur furnace is shown in Figure 2-14.

Loading...

Loading...