Issue 08/2013 Page 72

MAPLA- Modular energy supply system for load lifting magnets

Installation and commissioning

Generator installation for iMAPLA 8, 13, 17and 20

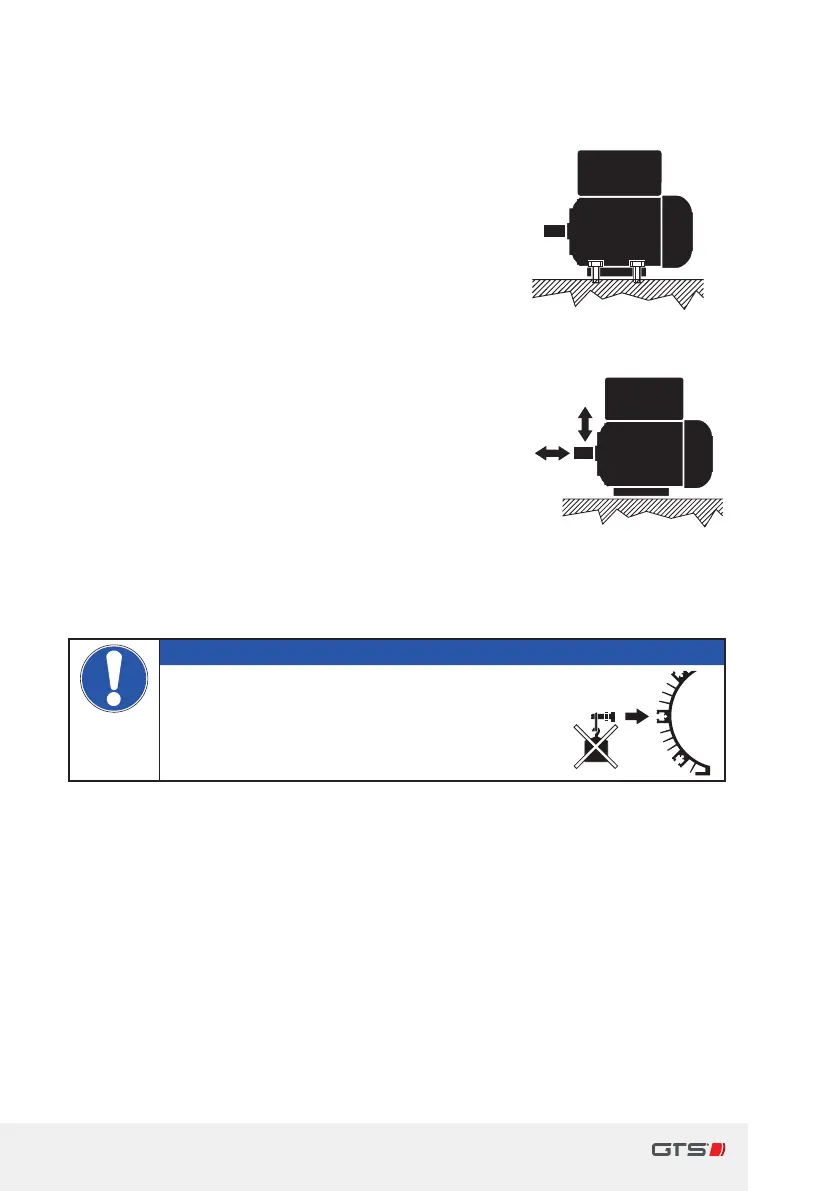

y Secure the generator with at least four mounting screws

(minimum M8or comparable, bolt grade

min.8.8).

y The attachment must be permanent and

resistant to shock and vibrations.

y Use suitable means to prevent the screws

from coming undone by themselves,

e.g.viaatension ring according to DIN 128.

Tightening torque for mounting screws

M = 25Nm

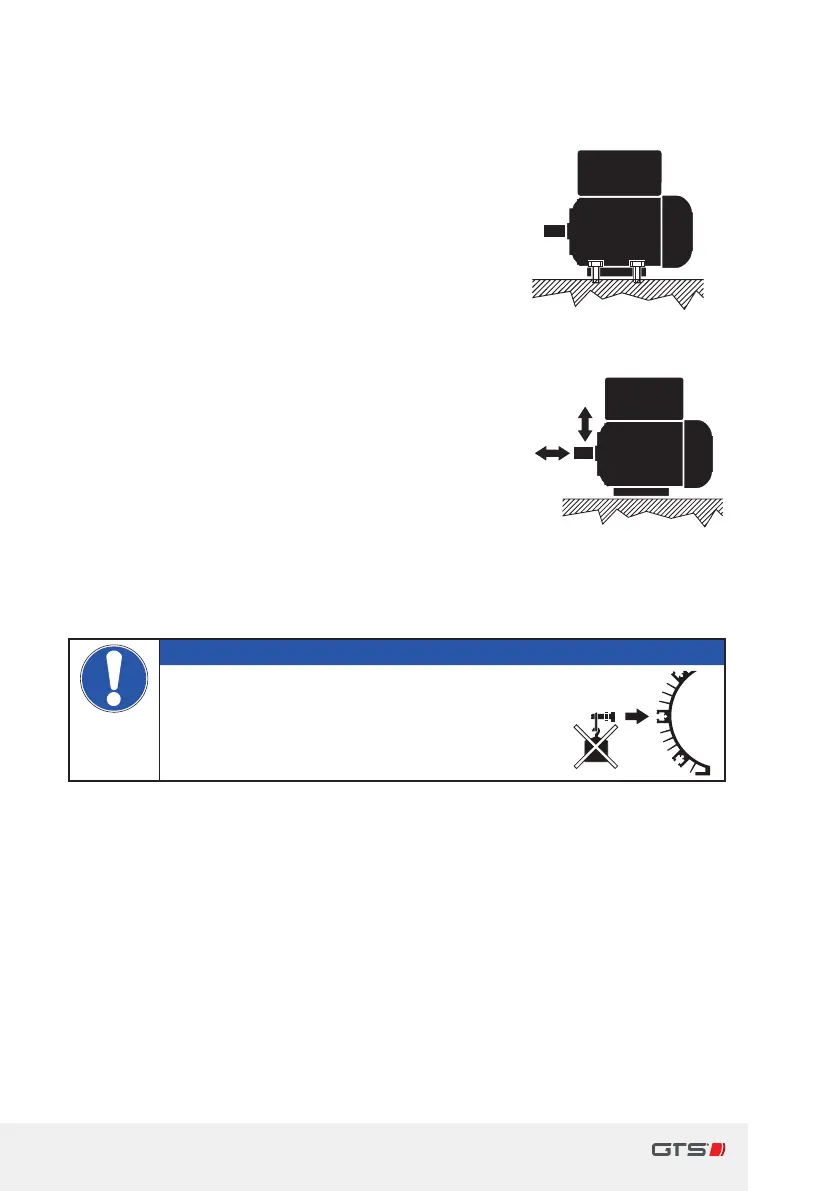

Permissible load on the shaft

Fr

max

= 2,000N for iMAPLA 8and 13

Fr

max

= 3,000N for iMAPLA 17and 20

(measured in a50mm axial clearance

from the point where the shaft exits

the bearing plate.

Fa

max

= 200N for iMAPLA 8and 13

Fa

max

= 380N for iMAPLA 17and 20

Important

► Do not attach any third party parts to

the mounting proles on the generator

housing.

5.5.4 Minimum clearances and cooling provisions

y The generator needs sucient ventilation for cooling. The cooling air is

drawn through the cooling proles by the fan wheel on the rear side of the

generator and across the housing, towards the front side.

y Ensure adequate air feed and exhaust openings.

y Comply with the following minimum clearances and note the regulations

for cooling.

4Mounting screws

Fr

Fa

max

max

Loading...

Loading...