HEIDENHAIN iTNC 530 487

12.6 Three-Dimensional Tool Compensation (Software Option 2)

12.6 Three-Dimensional Tool

Compensation (Software

Option 2)

Introduction

The TNC can carry out a three-dimensional tool compensation (3-D

compensation) for straight-line blocks. Apart from the X, Y and Z

coordinates of the straight-line end point, these blocks must also

contain the components NX, NY and NZ of the surface-normal vector

(see “Definition of a normalized vector” on page 488).

If, in addition, you want to carry out a tool orientation or a

three-dimensional radius compensation, these blocks need also a

normalized vector with the components TX, TY and TZ, which

determines the tool orientation (see “Definition of a normalized

vector” on page 488).

The straight-line end point, the components for the surface-normal

vector as well as those for the tool orientation must be calculated by

a CAM system.

Application possibilities

Use of tools with dimensions that do not correspond with the

dimensions calculated by the CAM system (3-D compensation

without definition of the tool orientation).

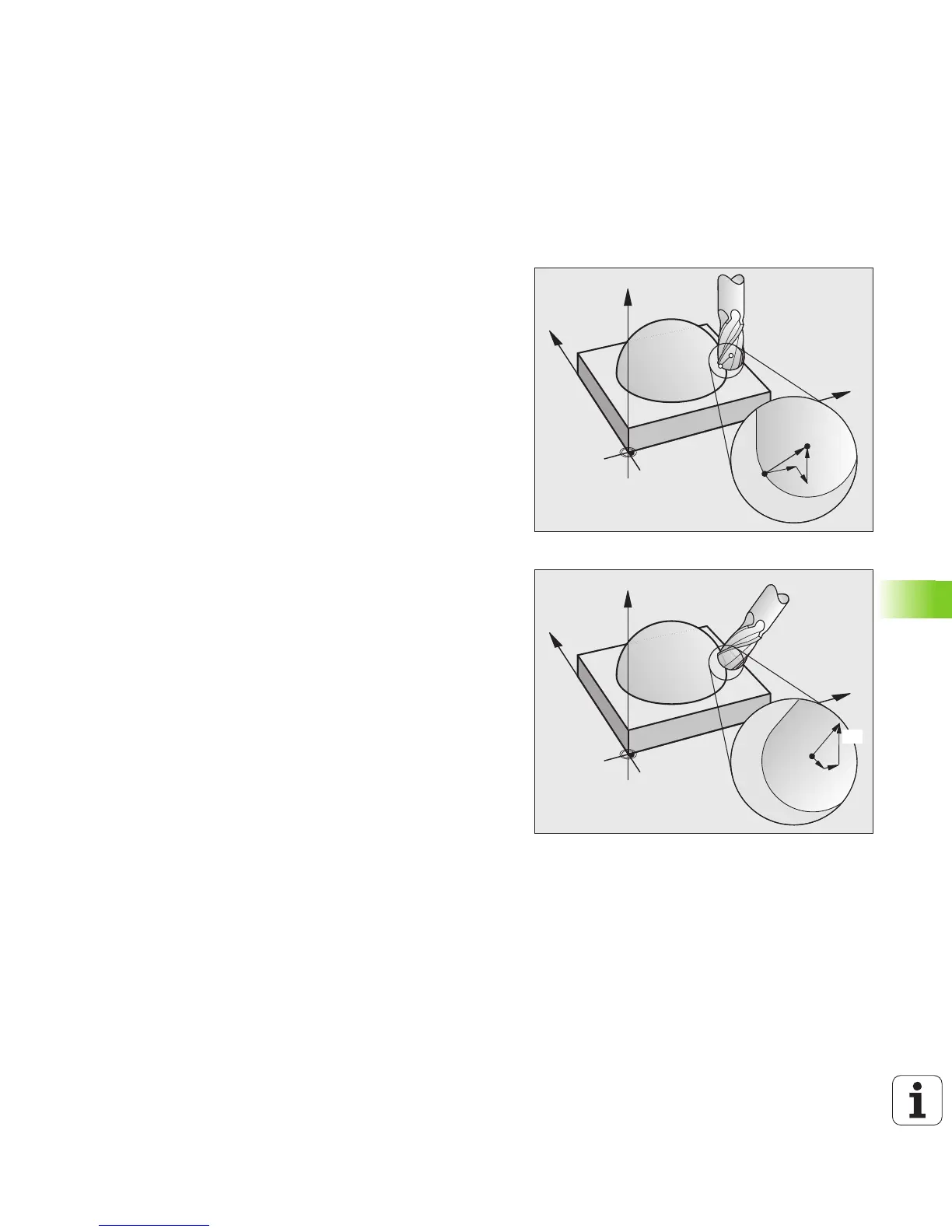

Face milling: compensation of the milling machine geometry in the

direction of the surface-normal vector (3-D compensation with and

without definition of the tool orientation). Cutting is usually with the

end face of the tool.

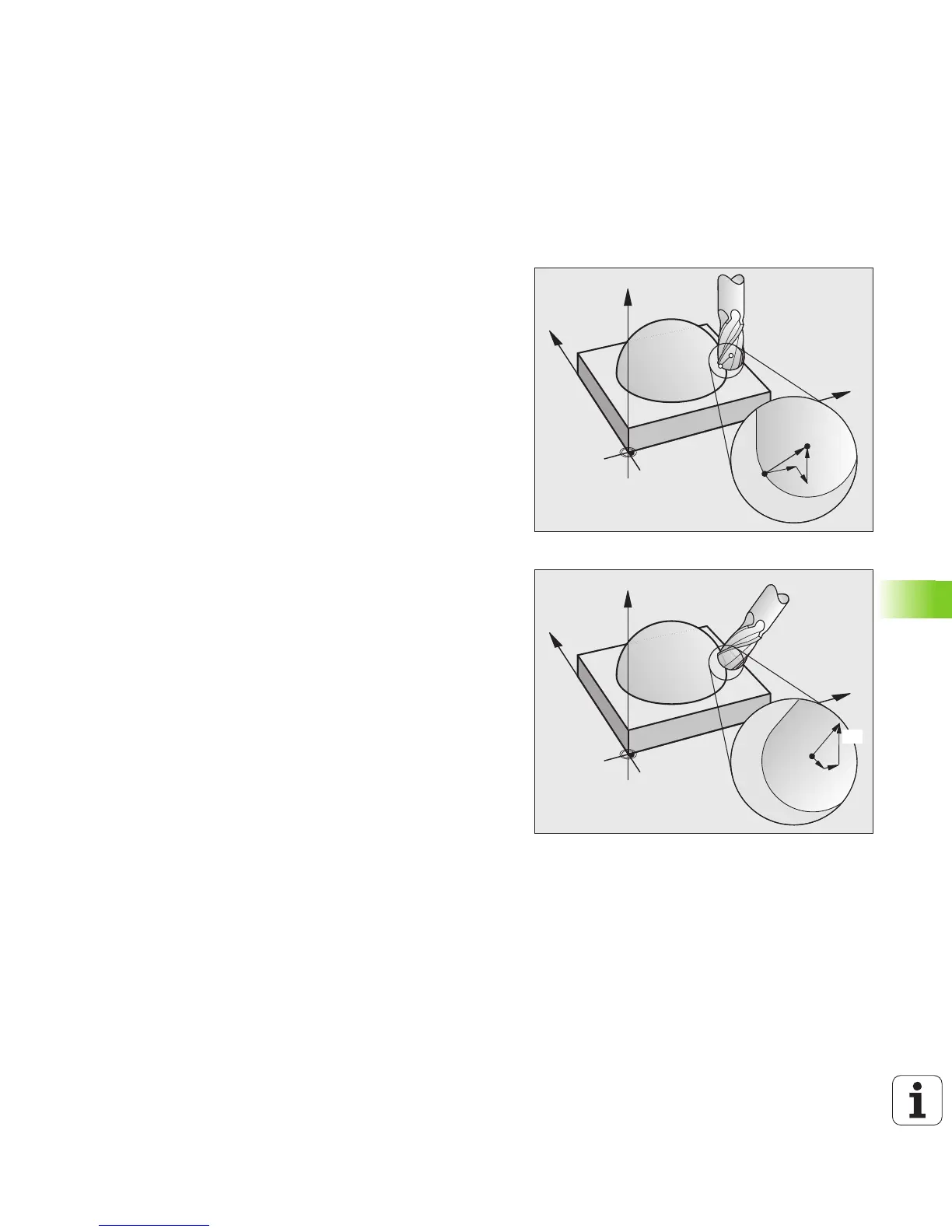

Peripheral milling: compensation of the mill radius perpendicular to

the direction of movement and perpendicular to the tool direction

(3-D radius compensation with definition of the tool orientation).

Cutting is usually with the lateral surface of the tool.

Loading...

Loading...