HEIDENHAIN iTNC 530 489

12.6 Three-Dimensional Tool Compensation (Software Option 2)

Permissible tool forms

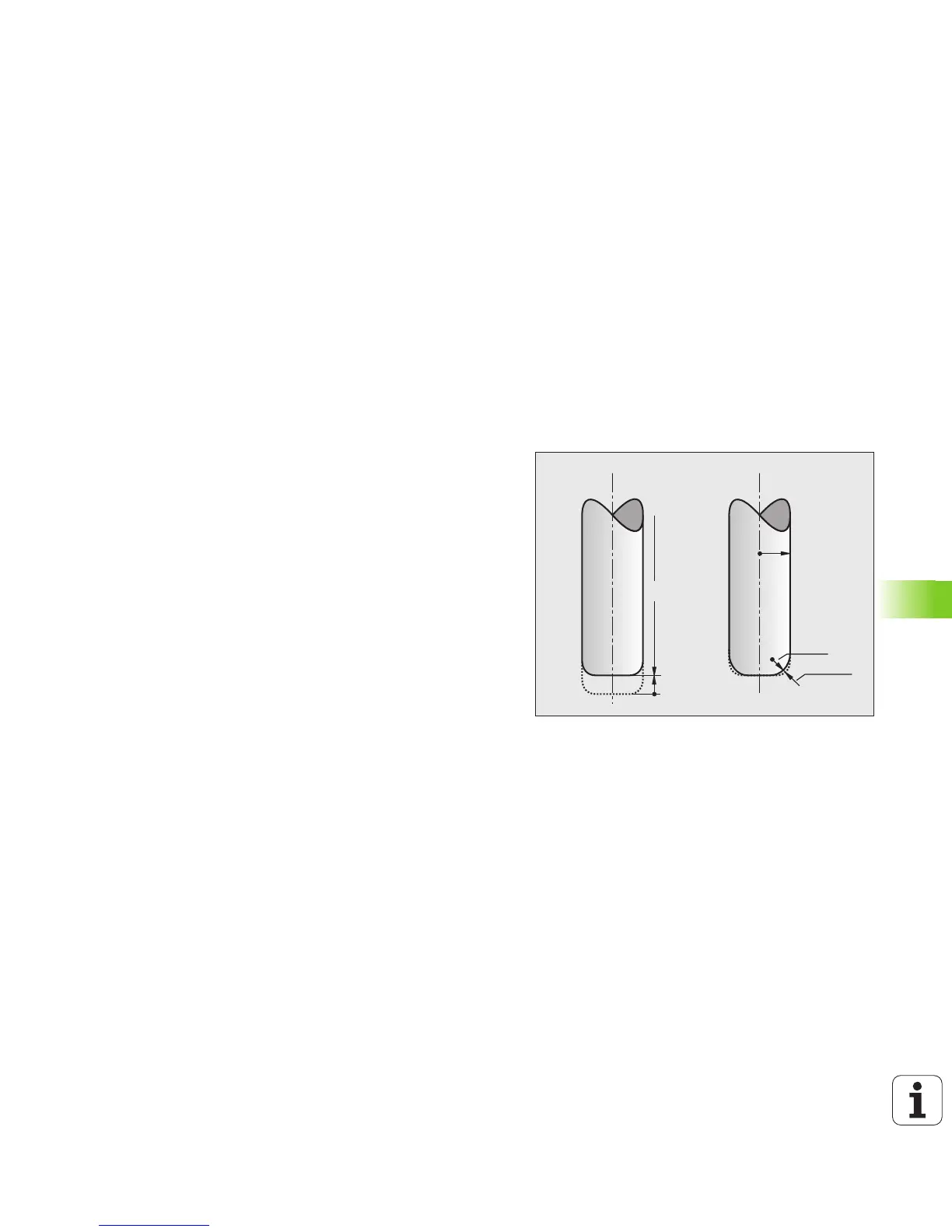

You can describe the permissible tool shapes in the tool table via tool

radius R and R2 (see figure):

Tool radius R: Distance from the tool center to the tool

circumference.

Tool radius 2 R2: Radius of the curvature between tool tip and tool

circumference.

The ratio of R to R2 determines the shape of the tool:

R2 = 0: End mill

R2 = R: Radius cutter

0 < R2 < R: Toroid cutter

These data also specify the coordinates of the tool datum P

T

.

Using other tools: Delta values

If you want to use tools that have different dimensions than the ones

you originally programmed, you can enter the difference between the

tool lengths and radii as delta values in the tool table or TOOL CALL:

Positive delta value DL, DR, DR2: The tool is larger than the original

tool (oversize).

Negative delta value DL, DR, DR2: The tool is smaller than the

original tool (undersize).

The TNC then compensates the tool position by the sum of the delta

values from the tool table and the tool call.

Loading...

Loading...