7-76

MAINTENANCE

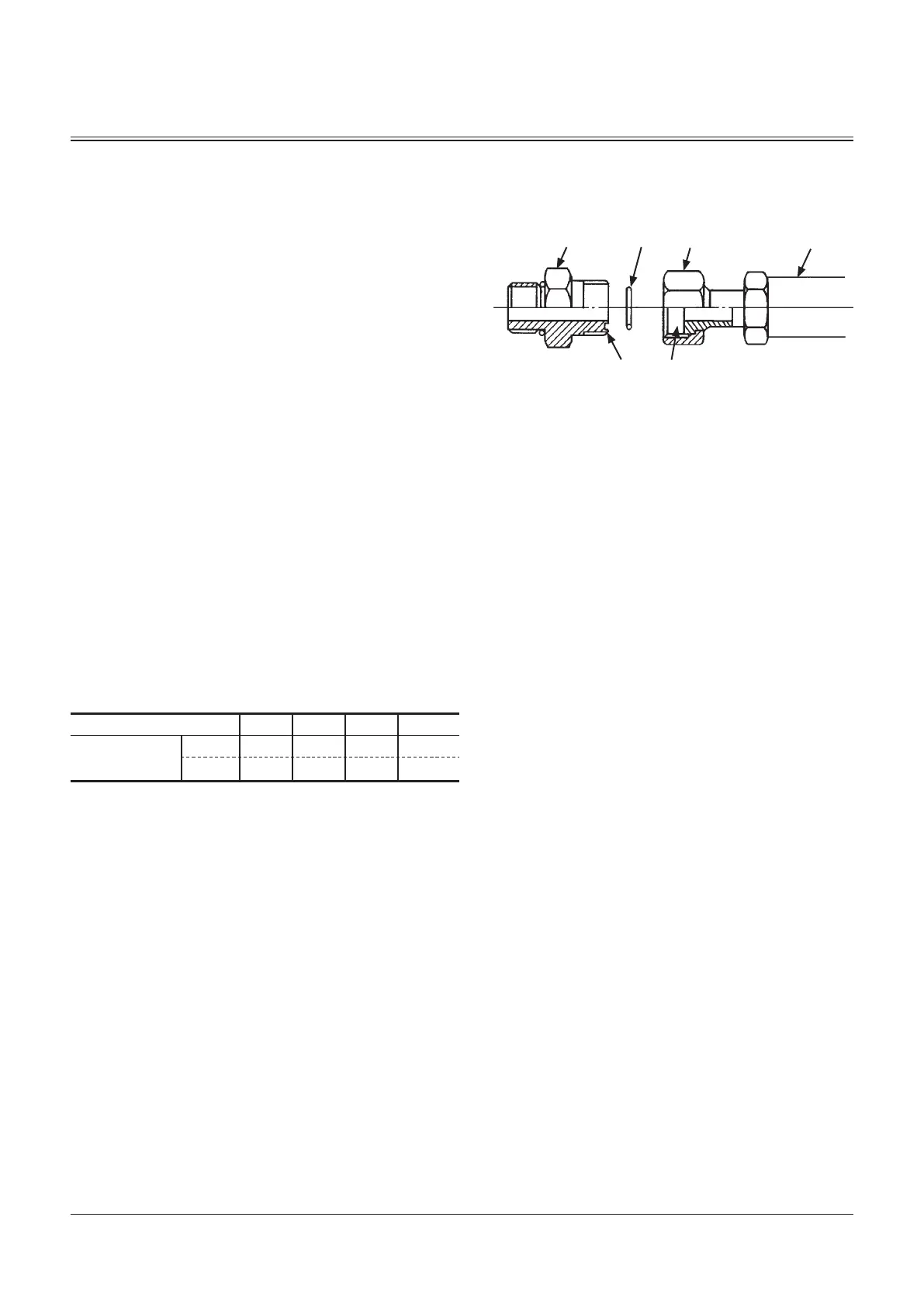

2 1 4 5

3

6

Service Recommendations for Hydraulic Fittings

Two hydraulic fitting designs are used on this machine.

Flat Face O-ring Seal Fitting (ORS Fitting)

O-ring (1) is used on the sealing surfaces of adapter (2) to

prevent oil leakage.

Precautions for Use

1. Replace O-ring (1) with a new one when assembling

fittings.

2. Check that O-ring (1) is properly fitted in O-ring groove

(3). Tighten union (4).

Tightening union (4) with O-ring (1) out of the groove

may damage O-ring (1) and cause an oil leak.

3. When assembling fittings, take care not to make a dent

on O-ring groove (3) of adaptor (2) and sealing surface

(6) on hose (5) or the side of the valve. Failure to do so

may result in damage to O-ring (1) leading to an oil leak.

4. If oil leaks from a loose connection of union (4), do not

tighten fitting. Open the connection, replace O-ring

(1) with new one and check for correct O-ring position

before tightening the connection.

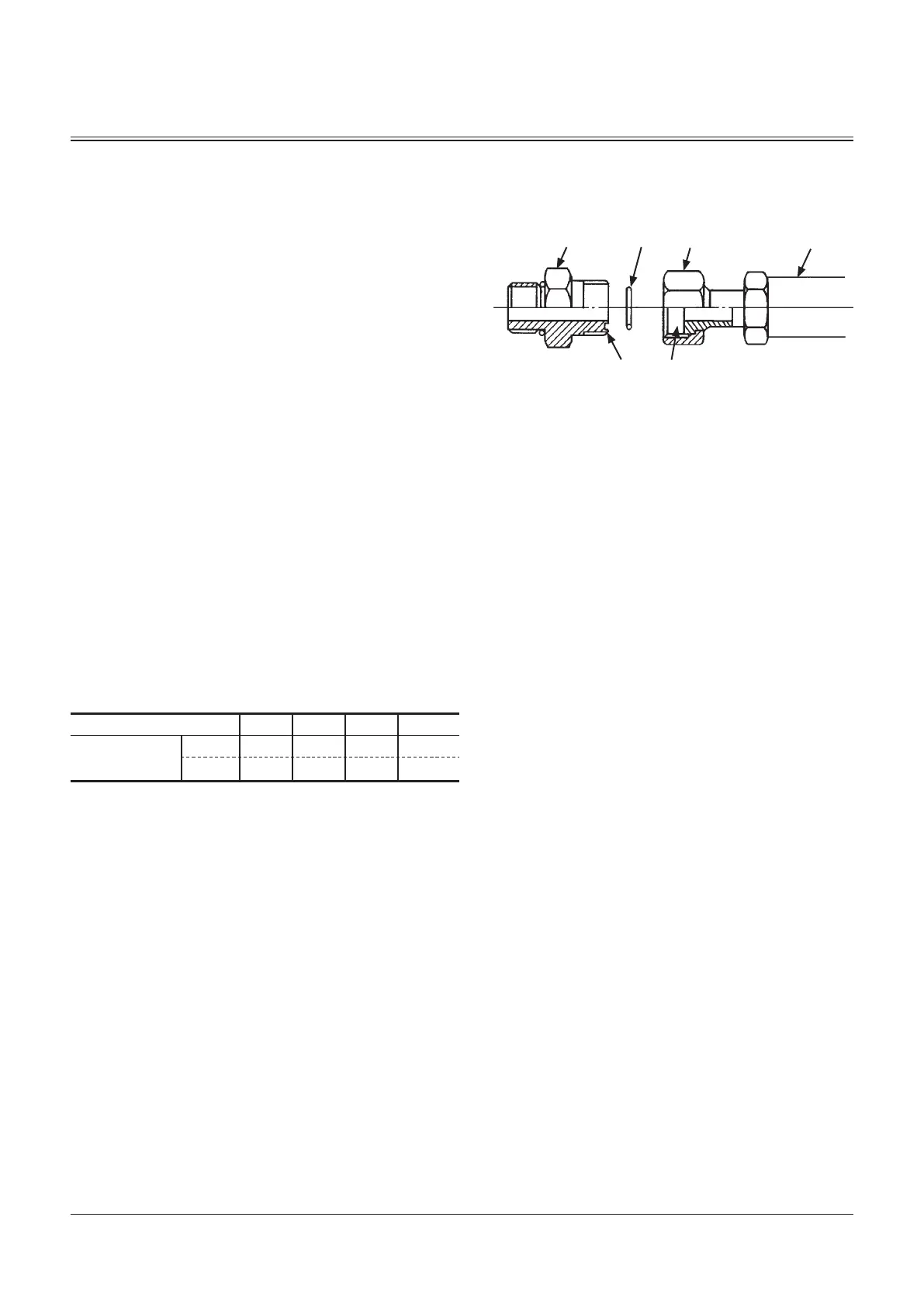

Tightening Torque:

Tighten fittings to the torque values shown below.

±10%

Wrench size (mm) 27 32 36 41, 46

Tightening

Torque

N·m 95 140 180 210

(kgf·m) (9.5) (14) (18) (21)

M104-07-033

Loading...

Loading...