7-12

MAINTENANCE

Maintenance Guide

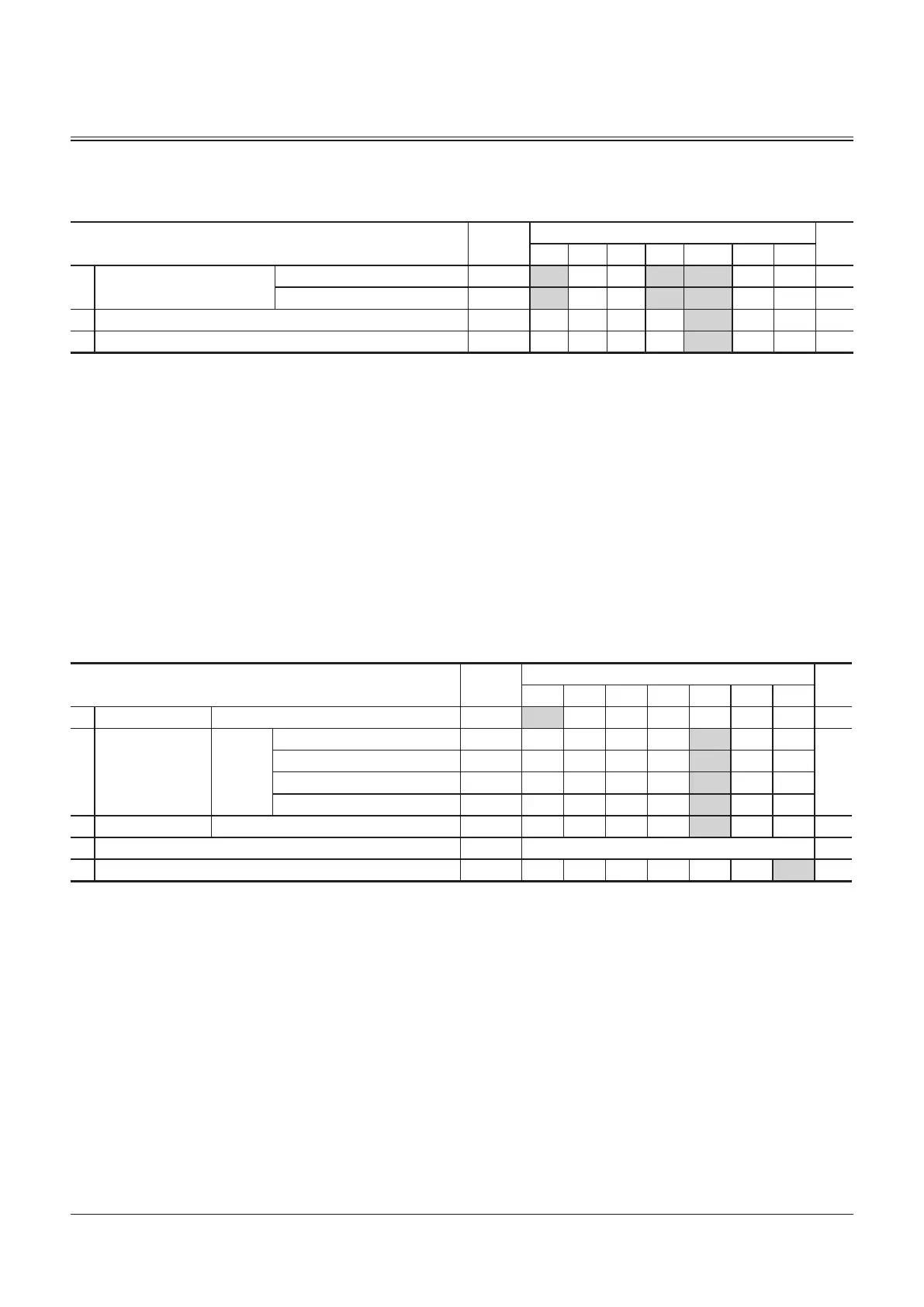

A. Greasing

Parts Quantity

Interval (hours)

Page

8 50 100 250 500 1000 2000

1. Front Joint Pins

Bucket and Link Pins 9

7-30

Others 11

7-30

2. Swing Bearing 2 7-32

3. Swing Internal Gear 1

7-33

: Add grease daily during first 50 hours of operation.

In case excavations are performed in water, grease the pin after operation is complete.

Shorten greasing intervals when the machine is operated under severe conditions or when the machine is

continuously operated for a long period of time.

: 250 hours for only first time.

: Check and add grease if necessary.

IMPORTANT:

Grease bucket and link pivots every day until break-in operation (50 hours) is complete.

When a bucket which does not have clearance adjustment mechanism such as slope-finishing bucket or

V-type bucket, or a genuine Hitachi hoe bucket before EX-5 model, or an attachment other than genuine

Hitachi bucket is used, grease two pins every 250 hours.

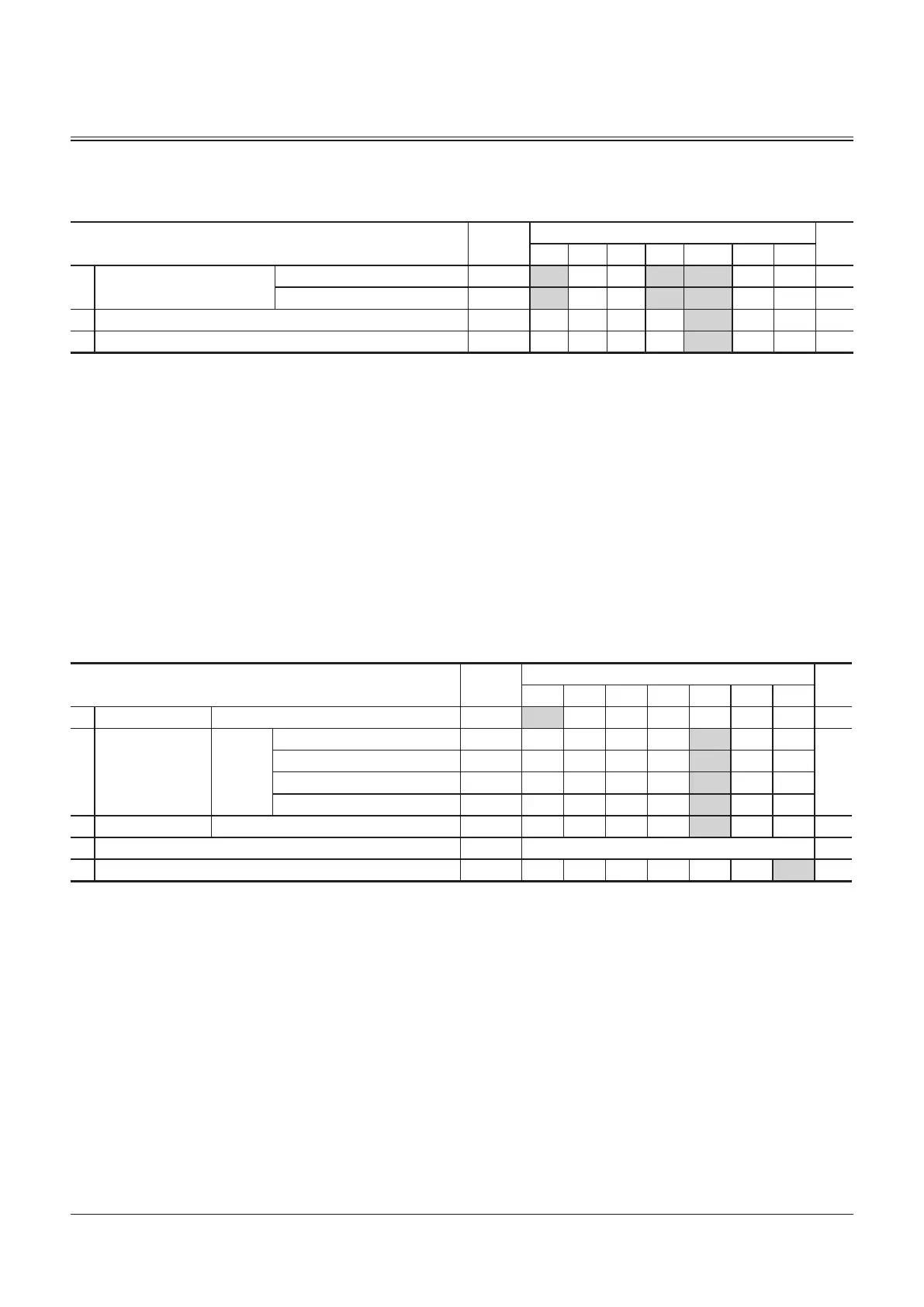

B. Engine

Parts Quantity

Interval (hours)

Page

8 50 100 250 500 1000 2500

1. Engine Oil Check Oil Level 1 7-53

2. Engine Oil Change

ZX120-6, 160-6 class 17 L

7-55

ZX200-6 class 23 L

ZX240-6 class 29 L

ZX300-6, 330-6 class 48 L

3. Engine Oil Filter Replace 1 7-55

4. Check and Clean Around the Engine − As required 7-58

5. Replace Oil Separator Element (ZX120-6, 160-6 class) 1 7-58

Loading...

Loading...