95

INTELLIGENT ACTUATOR

Part 1 Installation

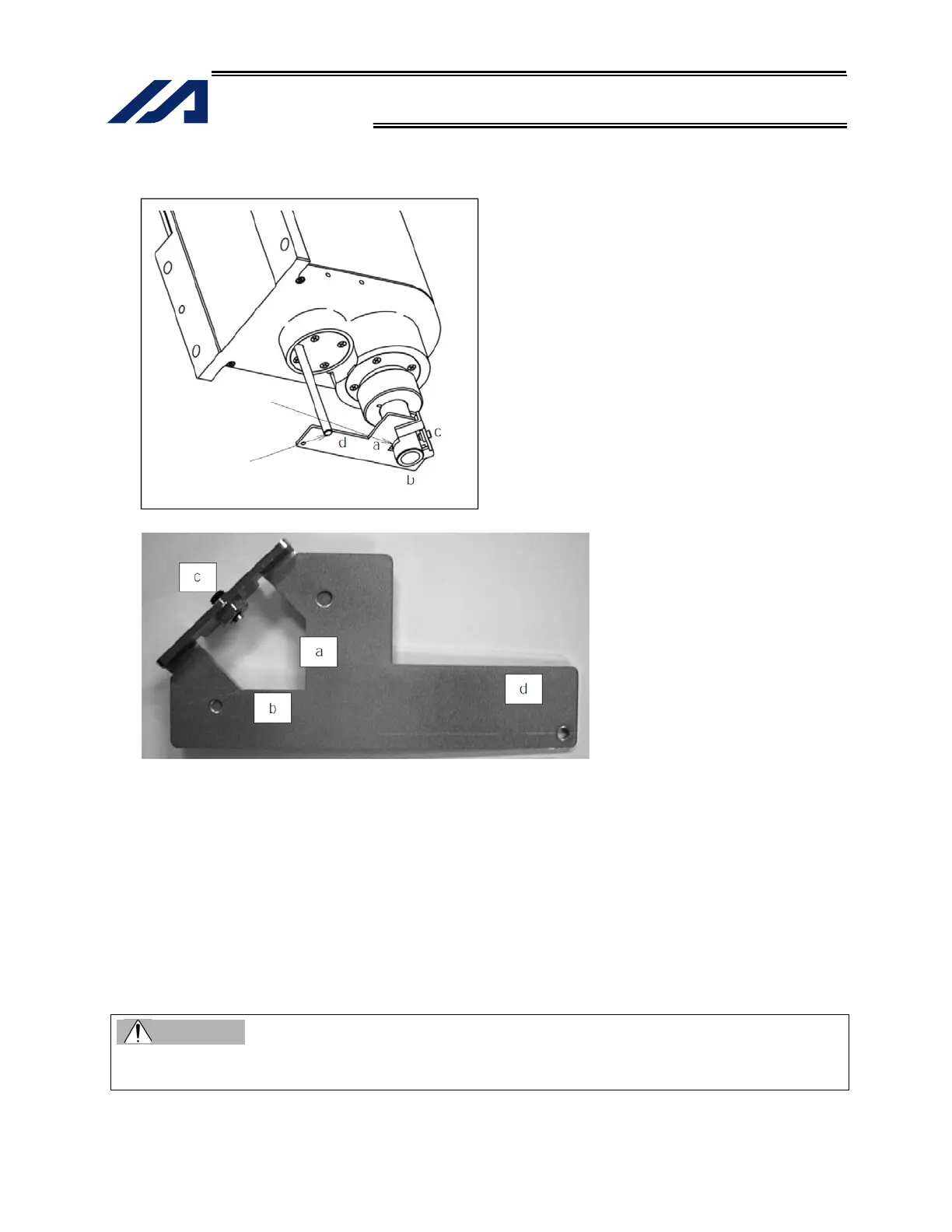

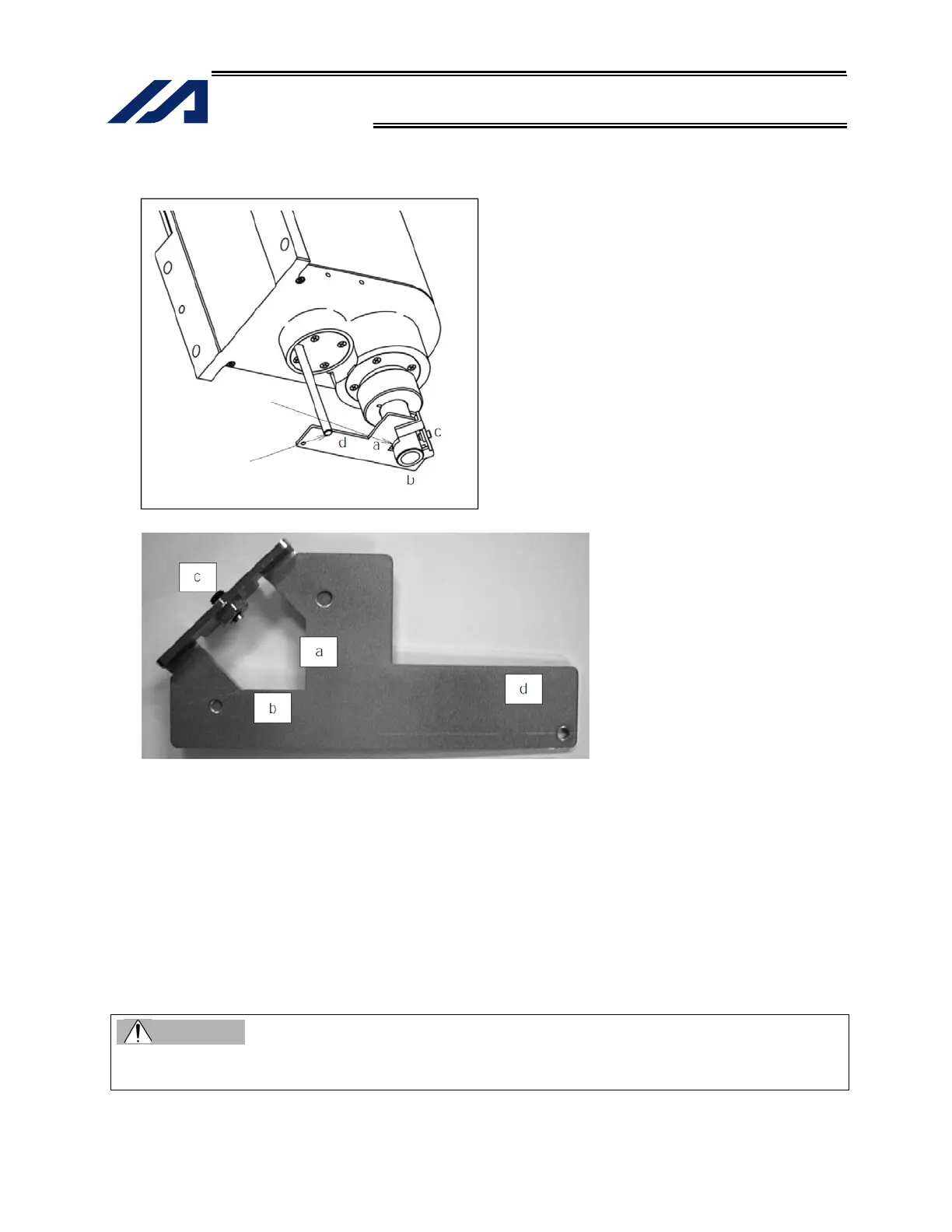

(12) Set the plate and pin constituting the adjustment jig, as shown below, to affix the robot in the

reference posture.

Installation method

[1] Insert the ball-screw spline into the hole in the jig from below.

[2] Cause the D-cut surface of the ball-screw spline to contact the surface a.

[3] Cause the side surface of the ball-screw spline to contact the surface b.

[4] Tighten the screw c to secure the jig onto the ball-screw spline.

* At this time, confirm that the adjustment jig is vertical to the ball-screw spline and that the D-cut

surface and surface a are firmly in contact.

* Applicable screw: Hexagonal socket head setscrew M5

* Tightening torque: 20 [N-cm] (reference)

[5] Insert the supplied shaft into the hole in the ZR unit.

* Exercise caution because the shaft will come off if the hand is released.

[6] Turn the ball-screw spline until the supplied shaft contacts lightly with the surface d of the jig.

Warning

Be sure to keep the emergency stop switch pressed while the adjustment jig is set. If not, the robot

may malfunction and cause serious injury.

D-cut surface

Shaft

Loading...

Loading...