Model 250

Printer Applicator

Operators/Technical Manual Section Six

Section 6 Page 10 of 20

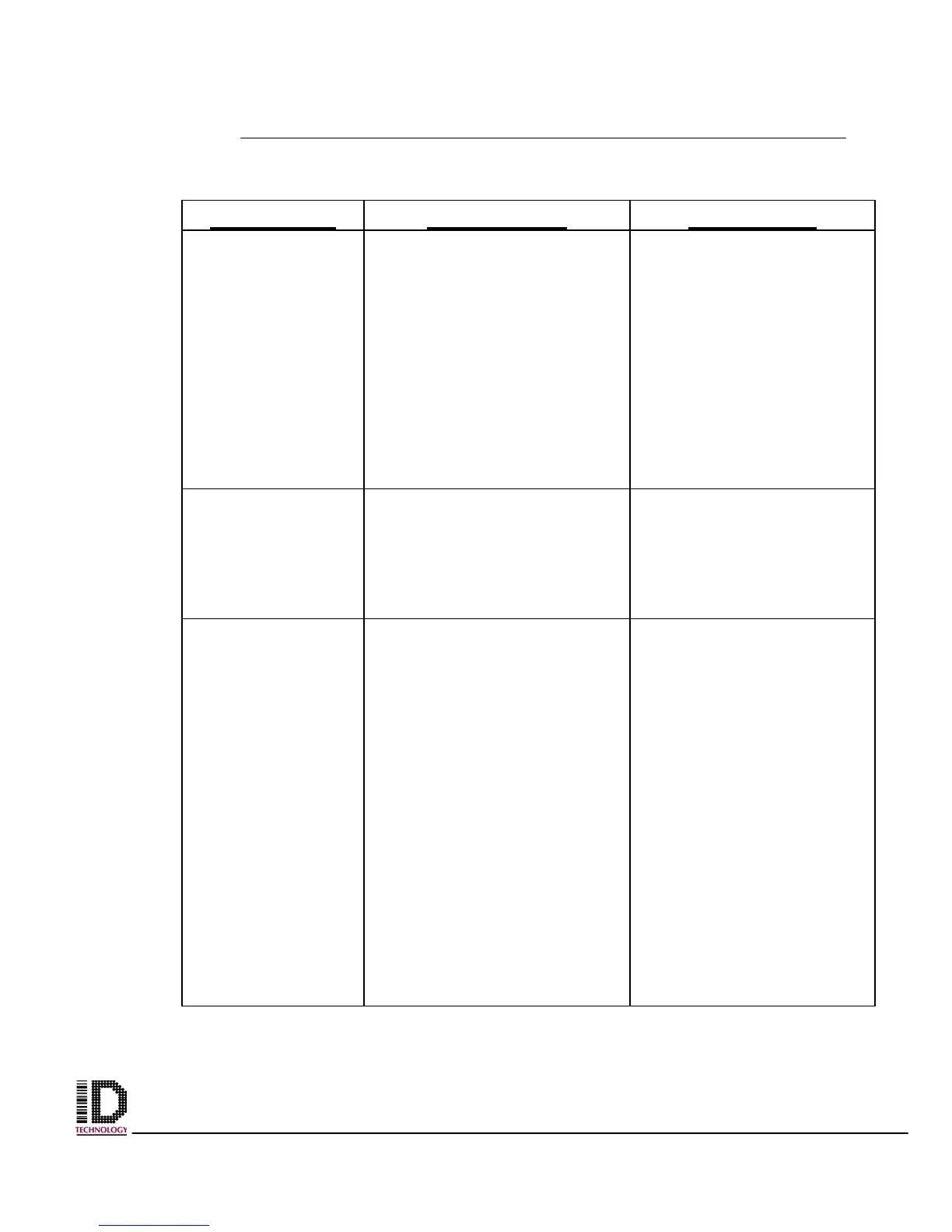

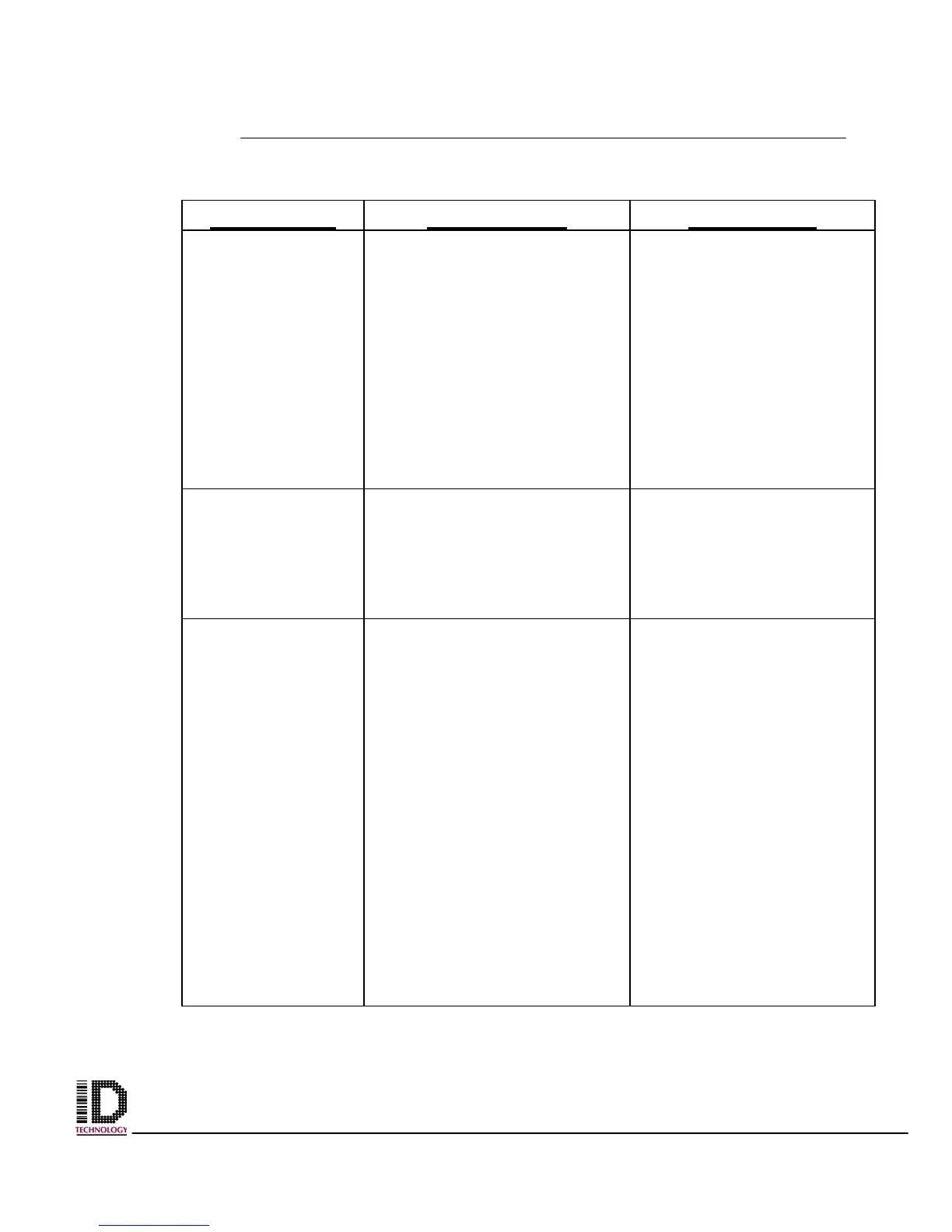

SYMPTOM DIAGNOSIS SOLUTION

Label advance

does not occur

1. Product detector

incorrectly aligned.

2. Product detector

disconnected from

machine or cable

damaged.

3. Applicator not ON-LINE.

4. Printer not ON-LINE.

Refer to 250 manual for

set-up instructions.

Correct or replace as

necessary.

Press JOG/RESET button

on applicator.

Correct.

Labels not being

held on tamp pad

after label advance.

1. Vacuum venturi adjusted

incorrectly or exhaust

blocked.

2. Air assist tube out of

adjustment.

Inspect and correct.

Refer to 250 manual for

adjustment.

Label placement on

tamp pad

consistently poor.

1. Air assist too high, too low

or incorrectly positioned.

2. Label stop out of

adjustment.

3. Insufficient vacuum due to

vacuum venturi control out

of adjustment.

4. Label detector sensitivity

out of adjustment.

5. Adhesive or other

obstruction on tamp pad

6. Die cut or adhesive strings

on label and liner.

Refer to 250 manual for

set-up instructions

Refer to Sato manual for

adjustment.

Inspect and correct.

Refer to Sato manual for

adjustment.

Clean tamp pad.

Replace label roll.

Loading...

Loading...