Model 250

Printer Applicator

Operators/Technical Manual Section Six

Section 6 Page 11 of 20

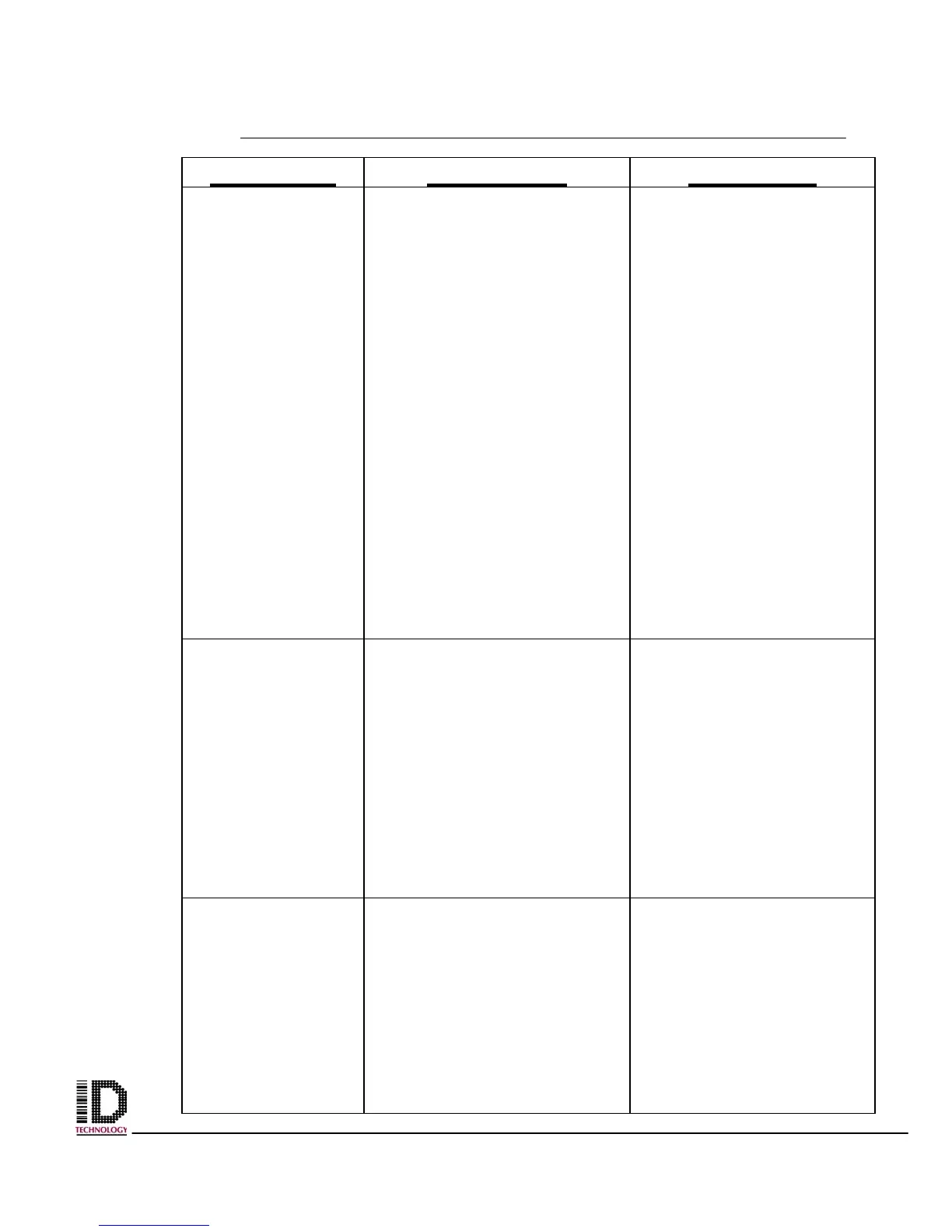

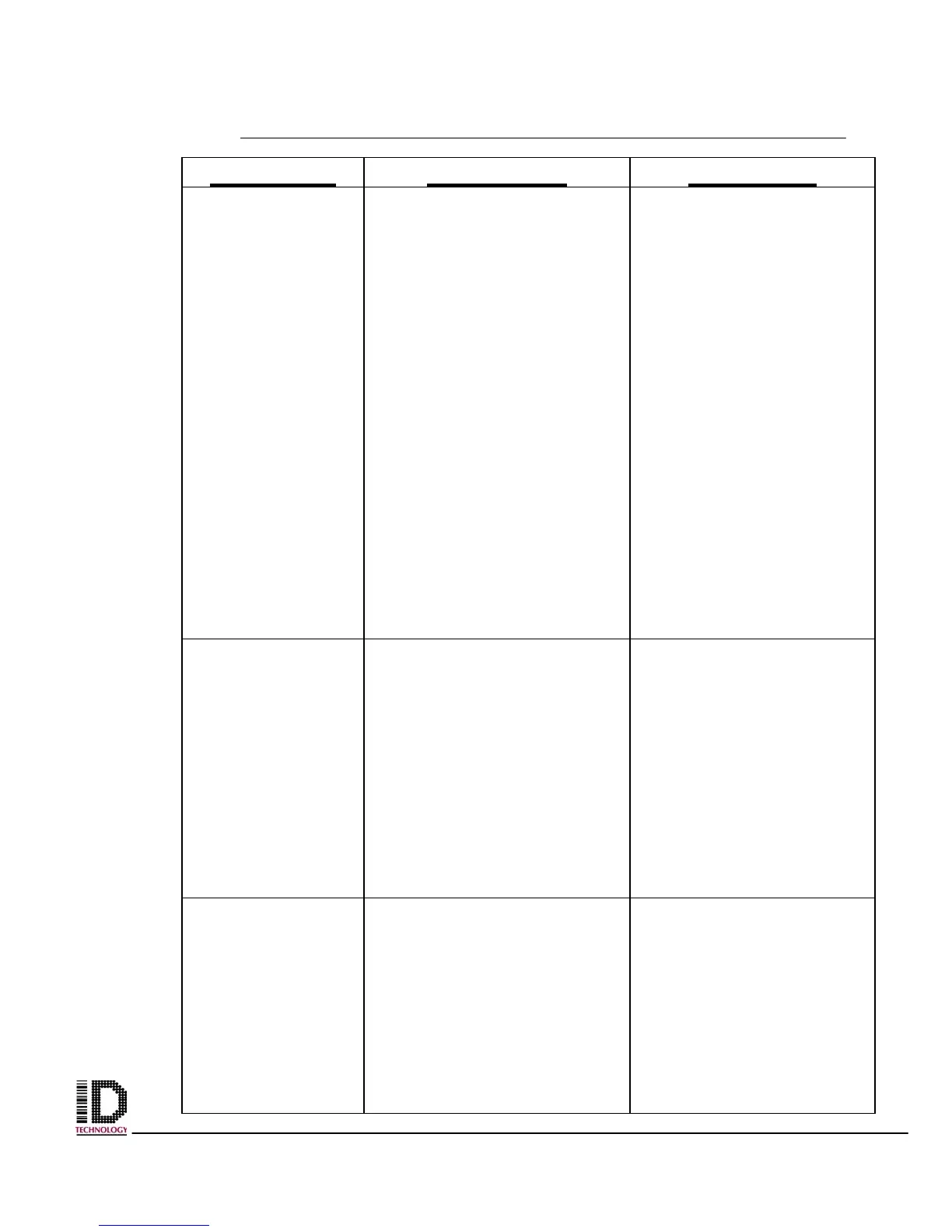

SYMPTOM DIAGNOSIS SOLUTION

Label placement on

product consistently

poor.

1. Fluctuation of product

conveyor speed.

2. Poor label adhesive.

3. Poor product guidance.

4. Product detector not

correctly positioned.

5. Incorrect product delay.

6. Smart tamp sensor out of

adjustment.

7. Poor placement of label

onto tamp pad.

Inspect and correct

Report to label

manufacturer if problem

persists.

Inspect and correct.

Refer to 250 manual for

set-up instructions.

Refer to 250 manual for

set-up instructions.

Inspect and correct.

Refer to “Label placement

on tamp pad consistently

poor”

Tamping does not

occur.

1. Applicator not connected

to air supply or air

pressure regulator turned

down.

2. Tamp solenoid or control

electronics malfunction.

3. Faulty Interface PCB.

4. Smart Tamp sensor not

working.

Inspect air pressure gauge

and correct as necessary.

Request qualified service

assistance.

Replace.

Inspect and correct or

replace.

Air assist does not

work

1. Applicator not connected

to air supply or air

pressure regulator turned

down.

2. Air solenoid or control

electronics malfunction.

3. Faulty Interface PCB.

Inspect air pressure gauge

and correct as necessary.

Request qualified service

assistance.

Replace.

Loading...

Loading...