Description of the control programs

60 Operating and Programming

5.10 I/O Device

In the I / O Device program, the motors and the inputs / outputs are controlled by a program

created in the higher-level control.

The speed setting of the motors is done by positive or negative percentage setpoints in the

corresponding output bytes. In the higher-level control, the "Move" command is used for this

purpose. The percentage reference value specification refers to the value "Normal speed" set in

the web server.

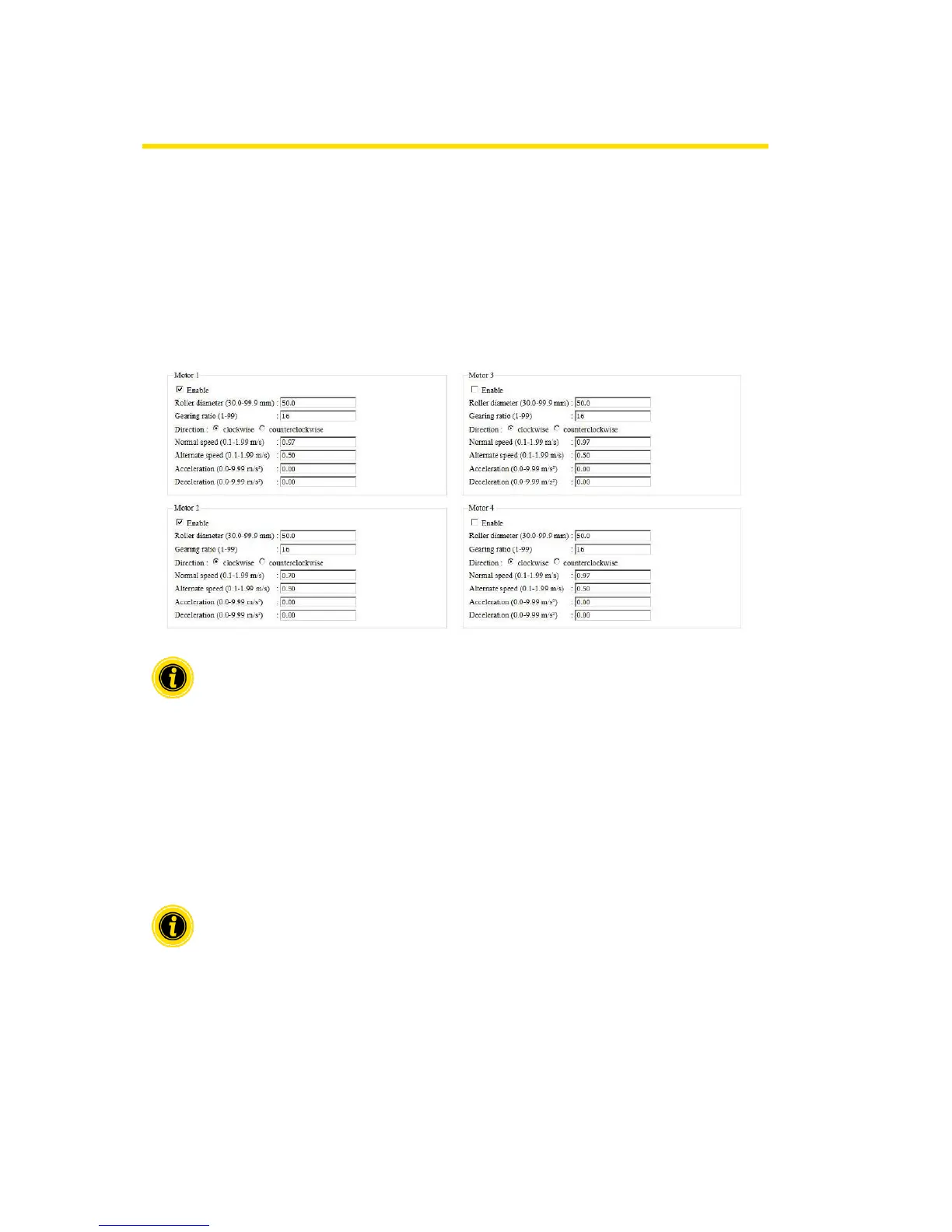

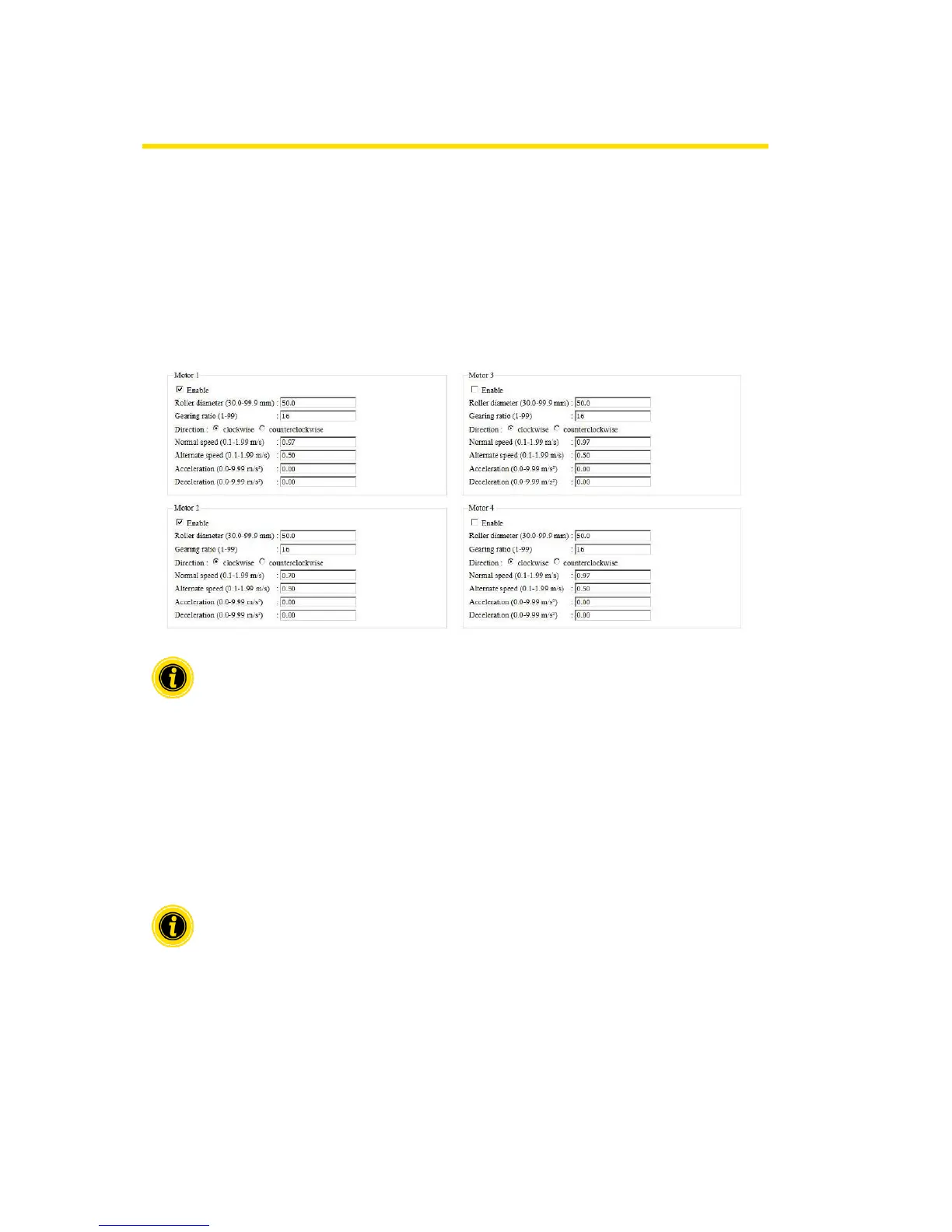

Unused motors must be deactivated to avoid error messages.

"Roller diameter", "Gearing ratio" and "Normal speed" must be set according to the RollerDrive

used.

With the parameter "Direction" the RollerDrive direction of rotation of the mounting position is

adapted accordingly (direction of rotation seen from the cable end of the RollerDrive).

"Acceleration" and "Deceleration" change the start-stop behaviour of the RollerDrive.

The parameter "Alternate speed" is only used in the process image "I/O Mode Tiny".

To apply the changed parameters to the MultiControl, press the "Submit" button.

Loading...

Loading...