Description of the control programs

Operating and Programming 37

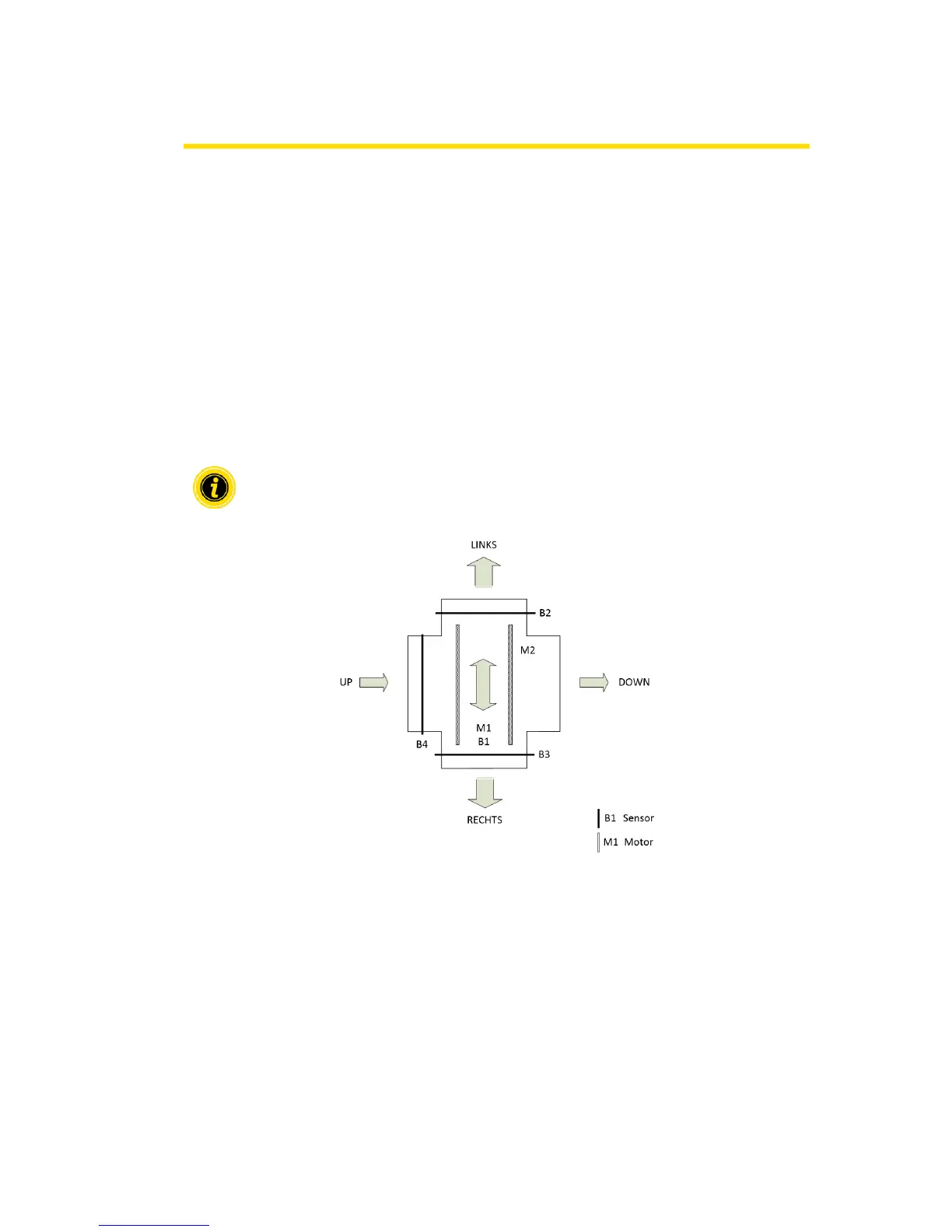

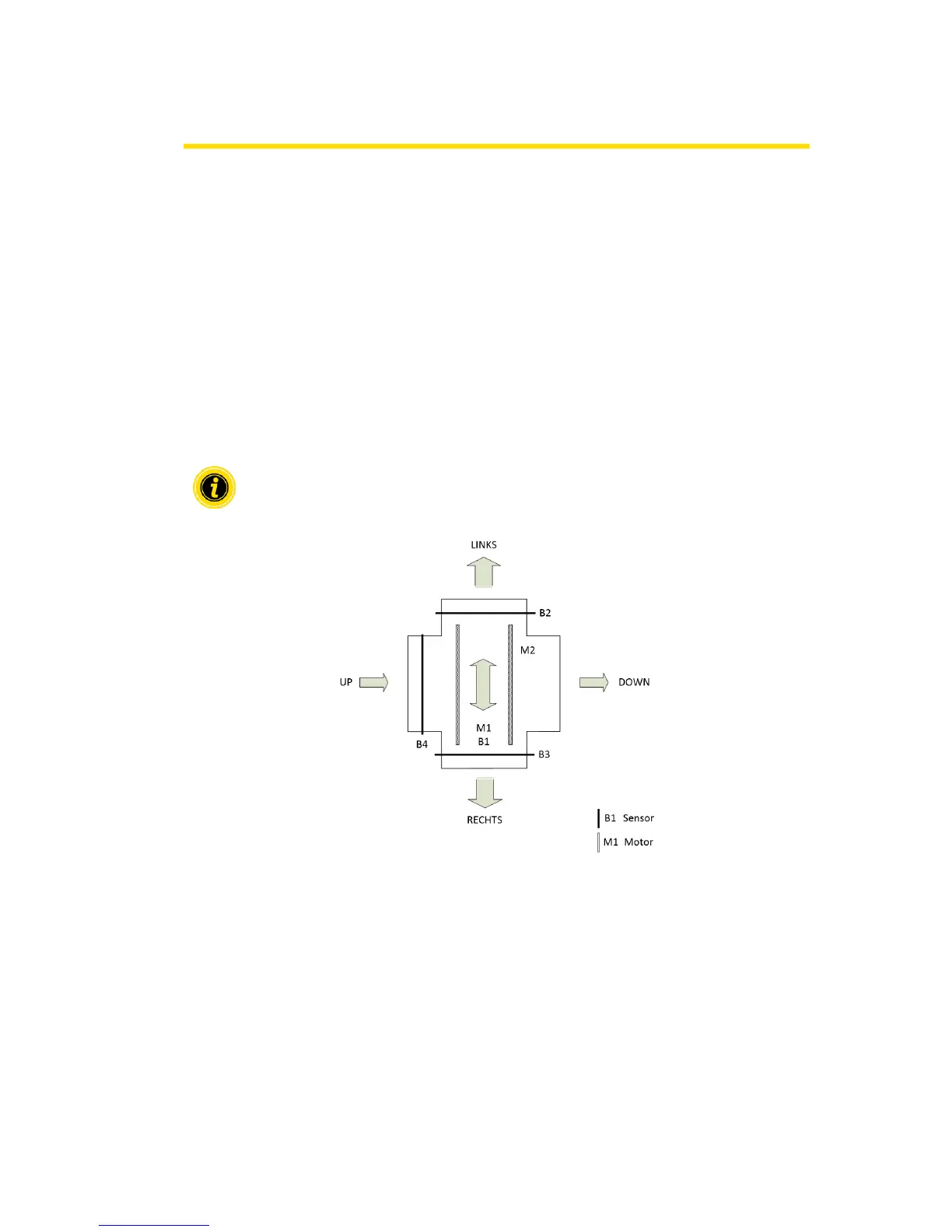

5.4 ZPA Transfer Out

With the "ZPA Transfer Out" program, up to two additional outfeeds can be distributed.

The decision where to convey an item is requested at the time of the promotion. This means the

sensors must be installed in a way that the information can be given in a timely manner. If this

cannot be guaranteed in time, it is recommended to set a stop function on the MultiControl of the

upstream conveyor in order to avoid errors during reading and transferring out.

If the downstream side conveyor is blocked, the conveyor belt is driven at a reduced speed.

Once the downstream unit is free, normal speed is resumed.

If an outfeed is blocked in the "Automatic distribution" setting, the remaining outfeeds are

automatically operated alternately in order to avoid jams (see table "merge prioritization").

Loading...

Loading...