30

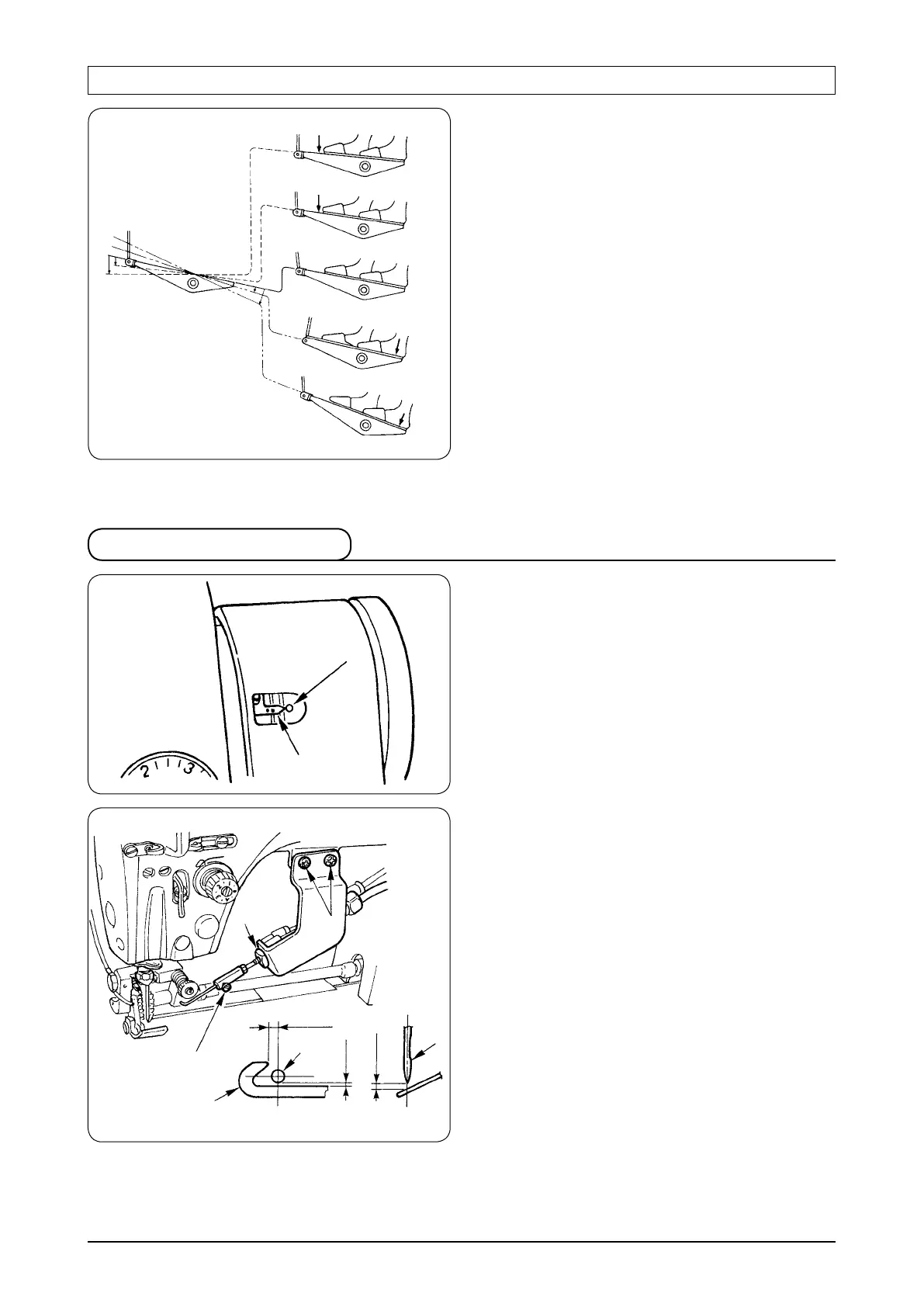

Adjust the wiper as follows when it is necessary to adjust it.

1) Turn the handwheel in the normal direction of

rotation to align white marker dot

1

engraved on the

handwheel with pointer

2

on the machine arm.

2) Loosen nut

3

, move wiper

4

and adjust the distance

between the wiper and needle

5

to –0.5 to 0.5 mm for

the adjustment of longitudinal direction

A

.

*

After the adjustment, securely tighten nut

3

.

(Tightening torque : 3 to 5 N·m)

(Note that the screw should face front.)

3) For adjusting vertical direction

B

, loosen screws

6

and adjust the distance from top end of needle to 1.5 to

2.5 mm.

4) For adjusting protruding amount

C

, loosen screw

7

and adjust the distance from needle to 0.5 to 1.5 mm.

*

After the adjustment, securely tighten screws

6

.

(Tightening torque : 3 to 4 N·m)

*

Check that the top end of the wiper does not come in

contact with the presser and the nger guard when the

wiper is in operation.

5. Adjusting the wiper

A

6

3

4

5

0.5 to 1.5

–0.5 to 0.5

1.5 to 2.5

C

B

5

7

1

2

Pedal operation

(1) The pedal is operated in the following four steps :

1) The machine runs at low sewing speed when you

lightly depress the front part of the pedal.

B

2) The machine runs at high sewing speed when you

further depress the front part of the pedal.

A

3) The machine stops (with its needle up or down) when

you reset the pedal to its original position.

C

4) The machine trims threads when you fully depress the

back part of the pedal.

E

5) The presser foot goes up when you lightly depress the

back part of the pedal

D

, and if you further depress the

back part, the thread trimmer is actuated.

• The machine will perform normal thread trimming even

if you depress the back part of the pedal immediately

following high or low speed sewing.

• The machine will completely perforrn thread trimming

even if you reset the pedal to its neutral position

immediately after the machine started thread trimming

action.

A

B

C

D

E

Loading...

Loading...