@

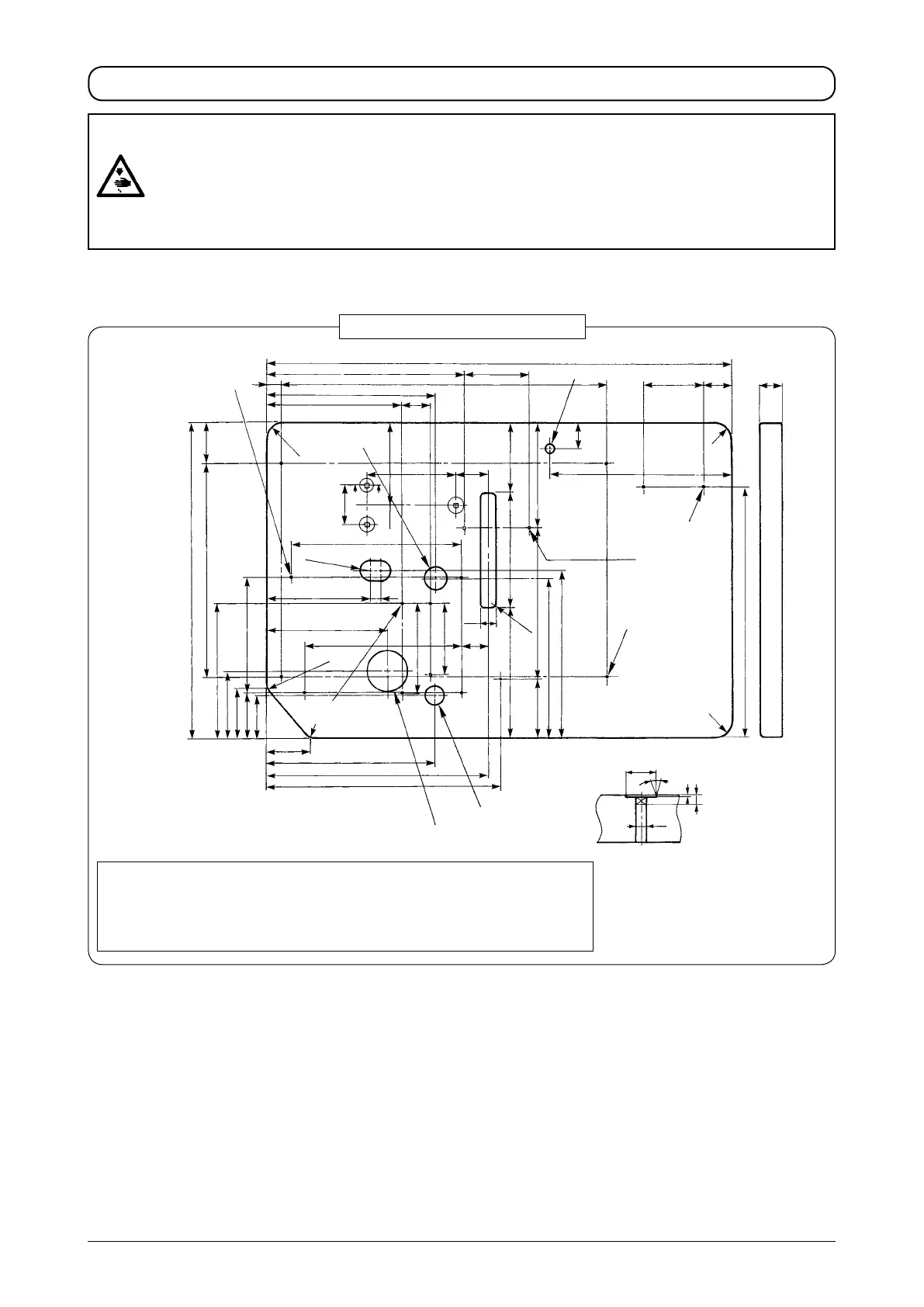

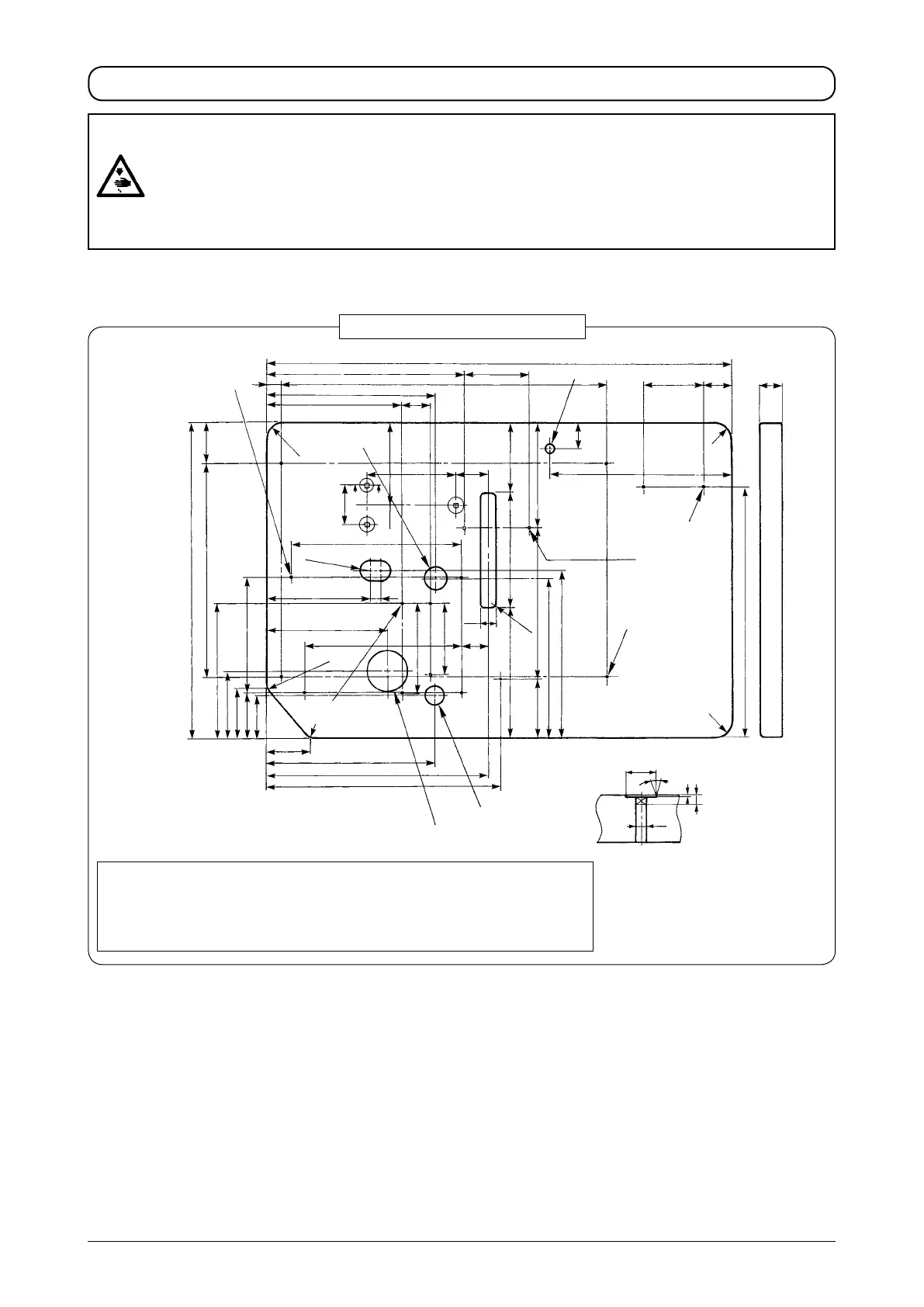

. INSTALLATION (COMMON TO BOTH MODELS)

< Table >

Arrange the relation of position between the table, motor, pneumatic components, etc. referring to the drawing of table below.

Drawing of table for reference

A

: Rubber cushion installing position (4 places)

B

: Position of wood screw for xing bobbin winder base (3 places)

C

: Position of wood screw for xing air unit (2 places)

D

: Position of wood screw for xing knee lifter unit (bottom surface) (4 places)

E

: Position of wood screw for xing table/stand (4 places)

Z-Z (3 places) Position of motor xing bolt

C

2×

φ

3.5 on the

bottom surface depth 10

E

4×

φ

3.5 on the

bottom surface depth 20

(For xing table/stand)

110

50

40

44

D

4×

φ

3.5 on the

bo tto m s ur fac e

depth 20

φ

40±0.5 drilled hole

A

4×

φ

3.5 depth 10

(Installing position of

rubber cushion)

240.5

70

360

535

351

116

830

24

300

580

49

Z

Z

227.7

114

85

78

74

195

75

298

393.3

414

278

φ

35 drilled hole

φ

70 drilled hole

213

183

20

R30

R30

R30

303

2×R 17.5

R30

325

R30

425

284

271

100

257

(178)

(120)

195220

4×R8

28

48.3

120.5

152

159

57

B

3×

φ

3.5 depth 10

φ

26

φ

8.5

30˚

8

1

66.5

140

φ

18 drilled hole

WARNING :

• Perform the installation of the sewing machine by the technical personnel who have been trained.

• To prevent personal injury, ask our dealer or the electrician for electric wiring.

• Be sure to perform the work with two persons or more when transporting the sewing machine and use a

lorry when moving it.

• To prevent personal injury caused by abrupt start of the sewing machine, do not connect the power plug

until the set-up of the sewing machine is completed.

• Be sure to earth the ground wire to prevent personal injury caused by leak.

• Be sure to attach safety protection cover, ger guard, etc.

Loading...

Loading...