Repair GL16

7-8

NOTE: The new doffer roll cover

should be spiral-wound at about a

45° angle. A steeper angle will use

more cover material. A shallower

angle will use less cover material.

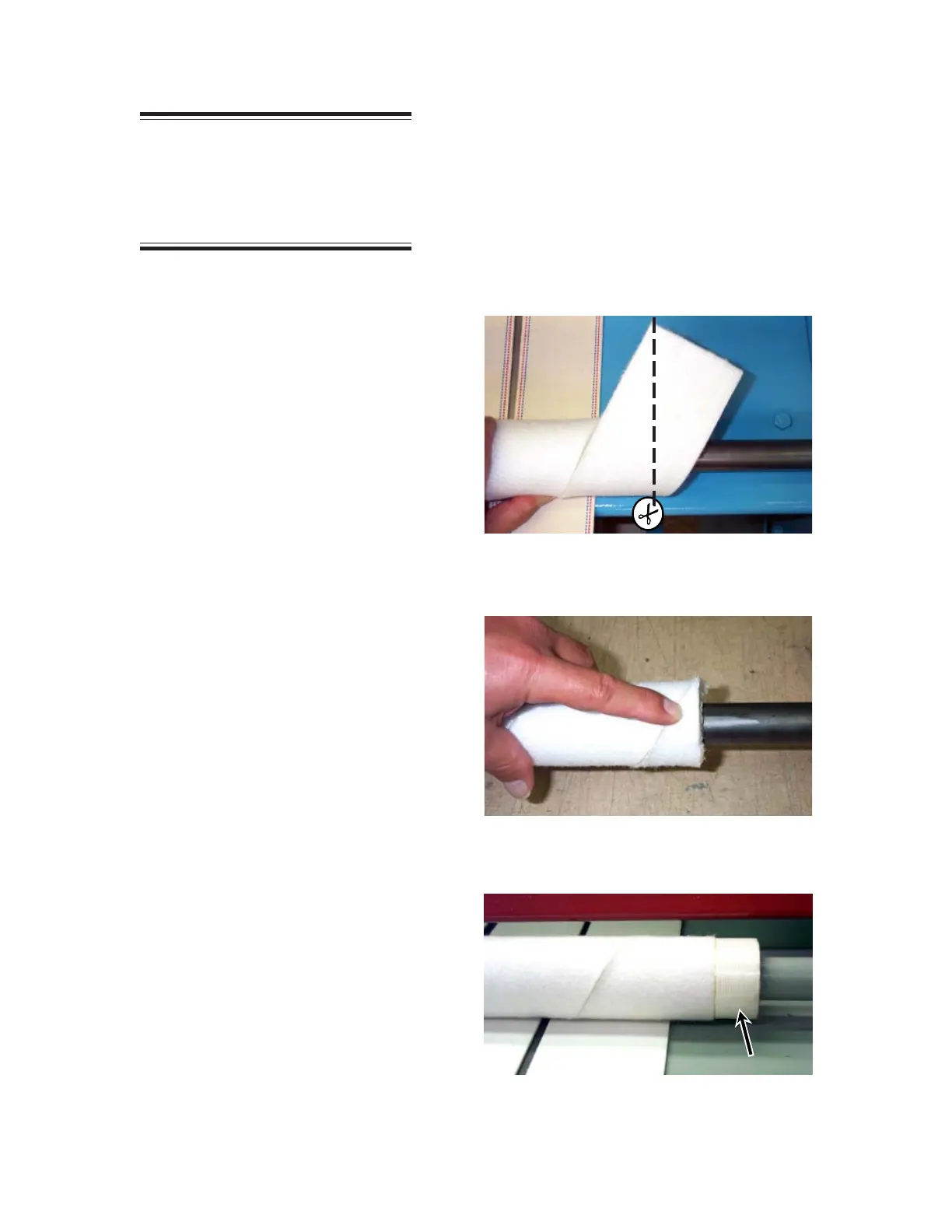

9. Once the angle has been determined, mark

and cut the cover at the start of the wind-

ing, parallel to the end of the roll (Figures

7-5 and 7-6).

10. In a strip along the full length of the doffer

roll, apply the cement evenly on 1/4 to 1/3

of the cylindrical surface. Smooth cement

with a putty knife.

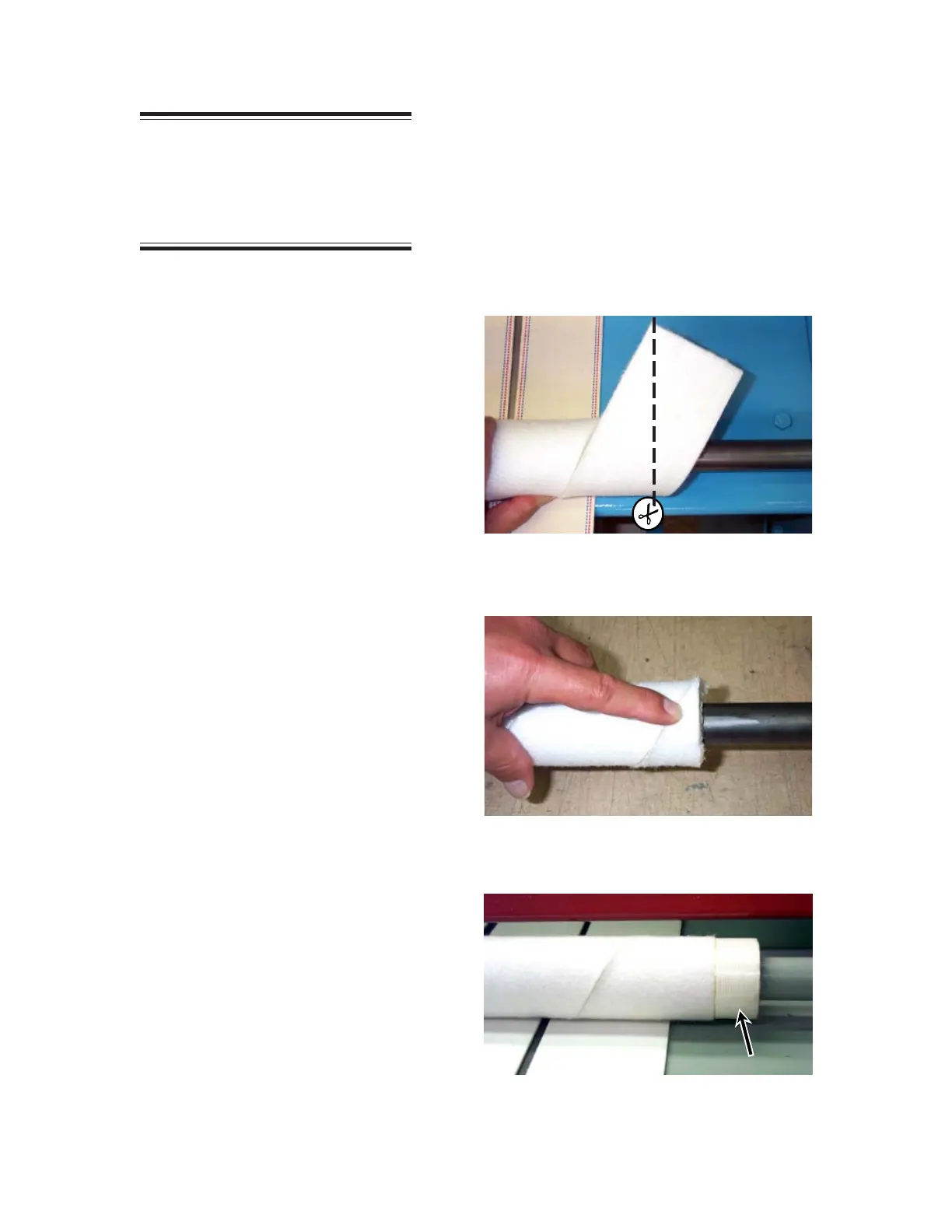

11. Position the starting edge at the end of

the roll and secure it with several wraps

of filament tape (Figure 7-7).

12. Carefully spiral-wind the cover onto the

roll, making sure that it goes on smoothly

without any gaps.

13. Trim off any excess cover material from

the end of the doffer roll. Secure the end

of the cover to the doffer roll with several

wraps of filament tape.

14. Remove the temporary protective cover-

ing from the feed ribbons and clean up

the area.

15. Align and overlap the ends of the first

guide tape. Be sure the trailing edge of

the guide tape is on top and the leading

edge is on the bottom (Figure 7-9). Staple

the ends together, placing a staple near

each end of the tape with one to three

additional staples spaced evenly between.

Repeat for the remaining guide tapes.

16. Remove the wooden wedges from the

slots, allowing the doffer roll to rest on

the feed ribbons.

17. Turn the power ON at the main discon-

nect switch.

Figure 7-6: When properly cut and positioned, the

cover should be flush with the end of

the doffer roll.

Figure 7-5: Mark and cut the cover at the start of

the winding, parallel to the end of the

roll.

18. Start the unit to make sure the cover is

secure and smooth against the doffer roll.

19. If any adjustment to the cover is neces-

sary, stop the unit and turn the power OFF

at the main disconnect switch before mak-

ing the adjustment.

Figure 7-7: Secure the end of the doffer roll cover

with several wraps of filament tape.

Loading...

Loading...