GL16 Repair

7-33

7.10 Burner System

Individual components of the burner system

may wear during normal use and may need

occasional repair, inspection, or adjustment. If the

burner is experiencing problems, first inspect and

clean the spark plug and pilot assembly. For more

information within this manual, go back to the

PREVENTIVE MAINTENANCE chapter,

Check/Clean Spark Plug and Pilot Assembly

procedure.

If the spark plug does not appear to be the

problem, the following procedures should be used

to maintain proper operation of the burner system:

• Pilot Air and Gas Adjustment

• Gas/Air Mixer Adjustment

• Gas/Air Mixer Cleaning

• Heat Shield Detachment From Burner

Assembly

• Replacing Heat Shield Without Removing

Burner Assembly

• Heat Shield Attachment To Burner

Assembly

• Burner Removal

• Burner Tip Maintenance

• Burner Installation

• Temperature Control Replacement

• Touchless Temperature Sensor

Replacement

• UV Flame Scanner Replacement

• UV Flame Scanner Alignment

Adjustment

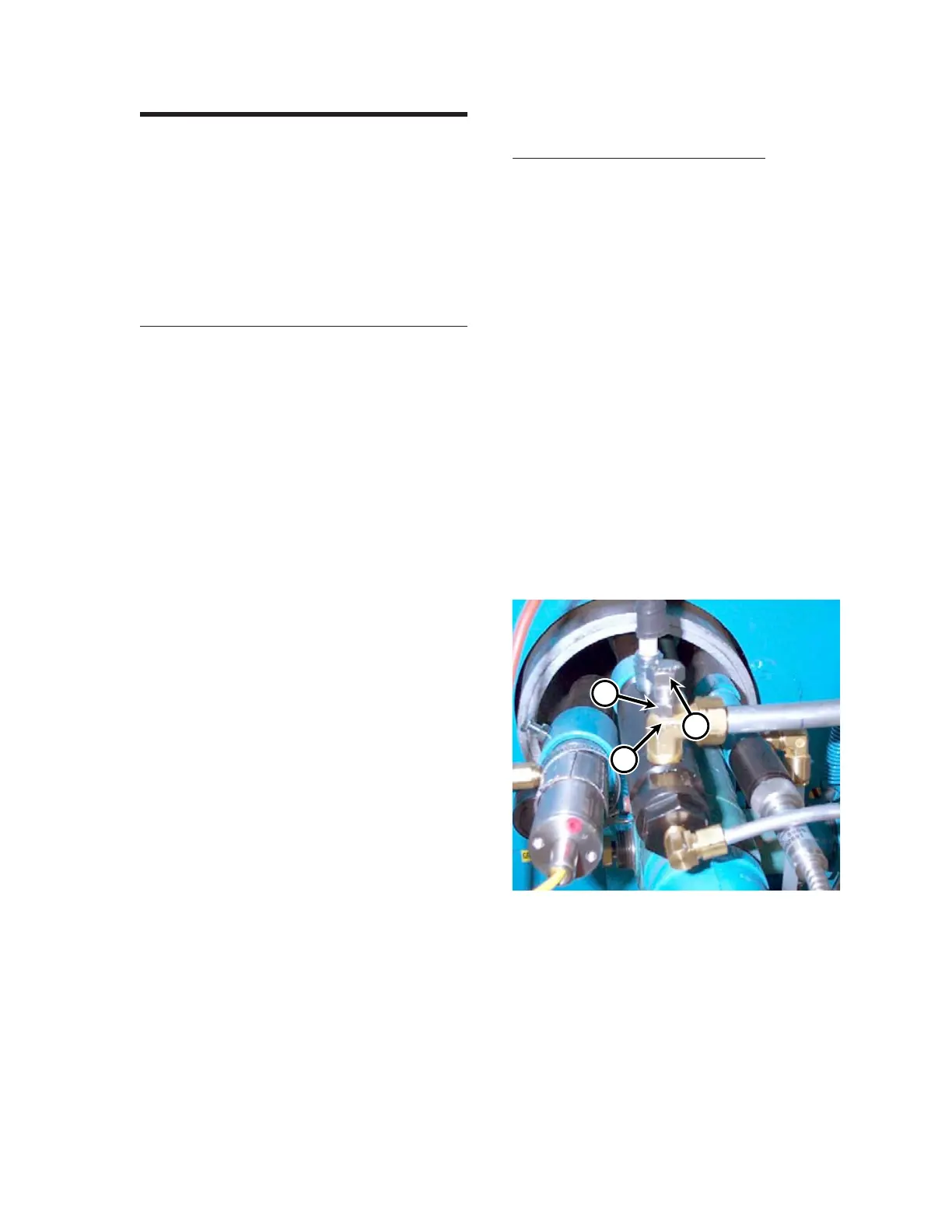

Pilot Air and Gas Adjustment

The gas pilot typically does not need adjustment.

However, with an air adjustment fitting (Figure

7-31, A) at the pilot burner combustion air

connection, the pilot flame can be adjusted for a

vigorous, reliable, and full flame.

If necessary, both the gas and combustion air

can be adjusted at the pilot. The flame length is

controlled by the manual gas valve at the pilot

valve and regulator assembly. The combustion air

can be adjusted with an adjusting screw (Figure

7-31, C) and locknut ( B) in the top of the pilot’s

brass air fitting. The flame must burn inside the

flame pipe from the spark plug to beyond the flame

pipe end. If the flame is quietly sitting on the end

of the pilot flame pipe, ignition may be unreliable.

A normal pilot flame will sound forceful.

Each gas heated unit is supplied with a manual

pilot gas valve that can be adjusted.

Figure 7-31: Adjust the pilot air and gas mixture at

fitting (A). Loosen the locknut (B)

and rotate the adjusting screw (C).

C

A

B

Loading...

Loading...