GL16 Repair

7-23

Compression Roll Pressure

Adjustment

1. Turn the power OFF at the main discon-

nect switch.

2. Open the end frame doors.

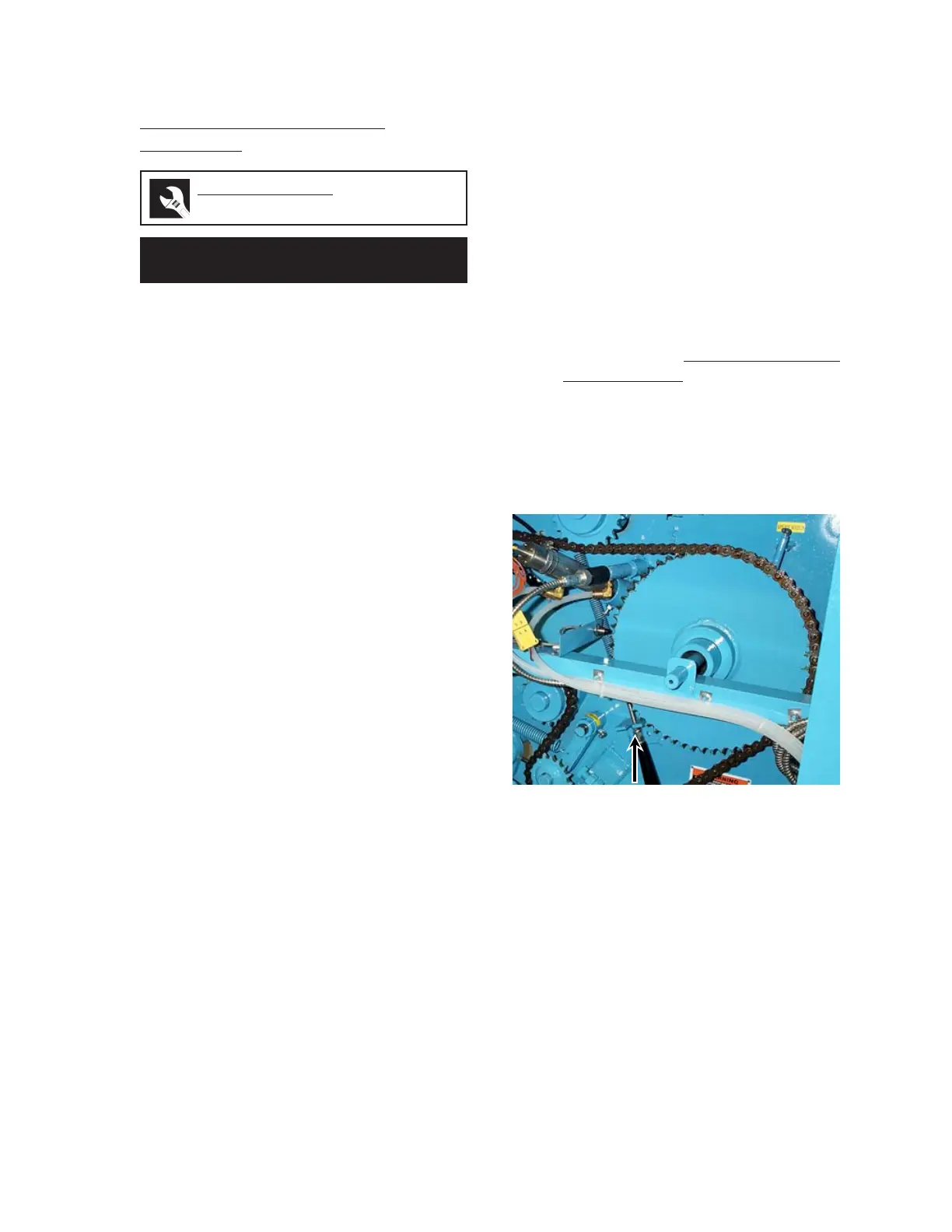

3. Make sure the compression roll spring-

loaded handles are disengaged from their

bracket slots in each end frame (Figure

7-22).

4. Locate the flat washer, adjusting nut, lock

washer, and locknut on the spring-loaded

handle in each end frame. These parts are

used to adjust the tension of the compres-

sion roll. When the handle is placed in the

bracket slot, it applies tension to the com-

pression roll springs.

5. Turn the adjustment nut toward the spring

to increase the tension and away to de-

crease. Tighten the locknut once the ad-

justment has been made.

6. Place the spring-loaded handles in their

bracket slots inside the end frame to add

tension to the compression roll.

7. Close and secure the end frame doors.

8. Turn the power ON at the main discon-

nect switch.

9. Press the green START button. Turn the

SPEED knob to the slowest speed.

10. Check for proper and even pressure along

the length of the compression roll. For

more information within this section, go

back to the

Compression Roll

Pressure Check procedure.

11. Repeat Steps 1-10 until the correct pres-

sure has been reached.

Perform only when the unit is OFF

(with power disconnected) and COOL.

Required Tools

wrench

Figure 7-22: The spring-loaded handles are

located in each end frame.

Loading...

Loading...