GL16 Installation

2-7

Ventilating the Work Area

A permanent fresh air supply or natural air

ventilation is required for the unit. In general, one

square inch is required for each 4,000 BTU/H up

to 400,000 BTU/H, plus one square inch for each

10,000 BTU/H in excess of 400,000 BTU/H.

Based on these standards, the makeup air

required for the unit is approximately 102 square

inches (660 cm

2

). However, local requirements

may differ. Check local regulations to determine

the exact makeup air requirements. Follow local

codes at all times.

WARNING

The room housing the unit

must be provided with

adequate makeup air to

ensure operator safety as

well as the proper operation

of the ironing section and

other fuel-burning equipment

in the area.

Electrical Connection

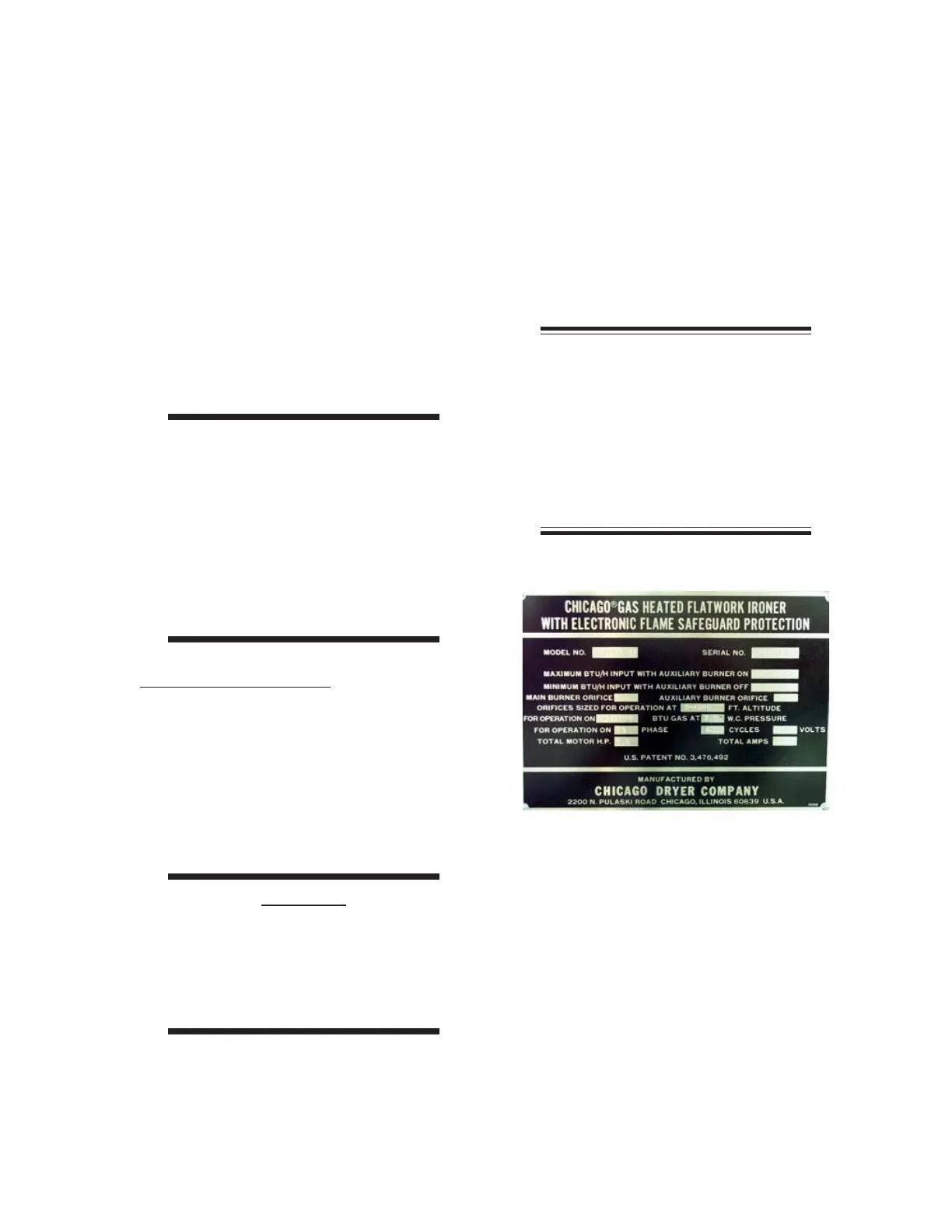

The nameplate, located at the back of the right

end frame, shows the electrical requirements of

the unit (Figure 2-11). All labor and materials

required to bring the electrical service to the unit

are a local responsibility. All electrical wiring must

comply with local codes, and a qualified electrician

should size the wiring.

CAUTION

The incoming electric power

service must match the

specific electrical

requirements shown

on the nameplate.

Refer to the nameplate to determine the power

supply requirements. If high or low voltage is

suspected, check the electrical service to

determine the actual voltage conditions. Improper

or fluctuating voltage will cause the safety

systems to interrupt the burner system operation,

possibly damage motors and other electrical

system components, and void the factory

warranty.

NOTE: A fused, main

disconnect switch has been

incorporated into the main

electrical box. Check local

regulations to determine whether

a separate external fused

disconnect switch is still required.

Follow local codes at all times.

Figure 2-11: The nameplate contains important

information.

Loading...

Loading...