Repair GL16

7-12

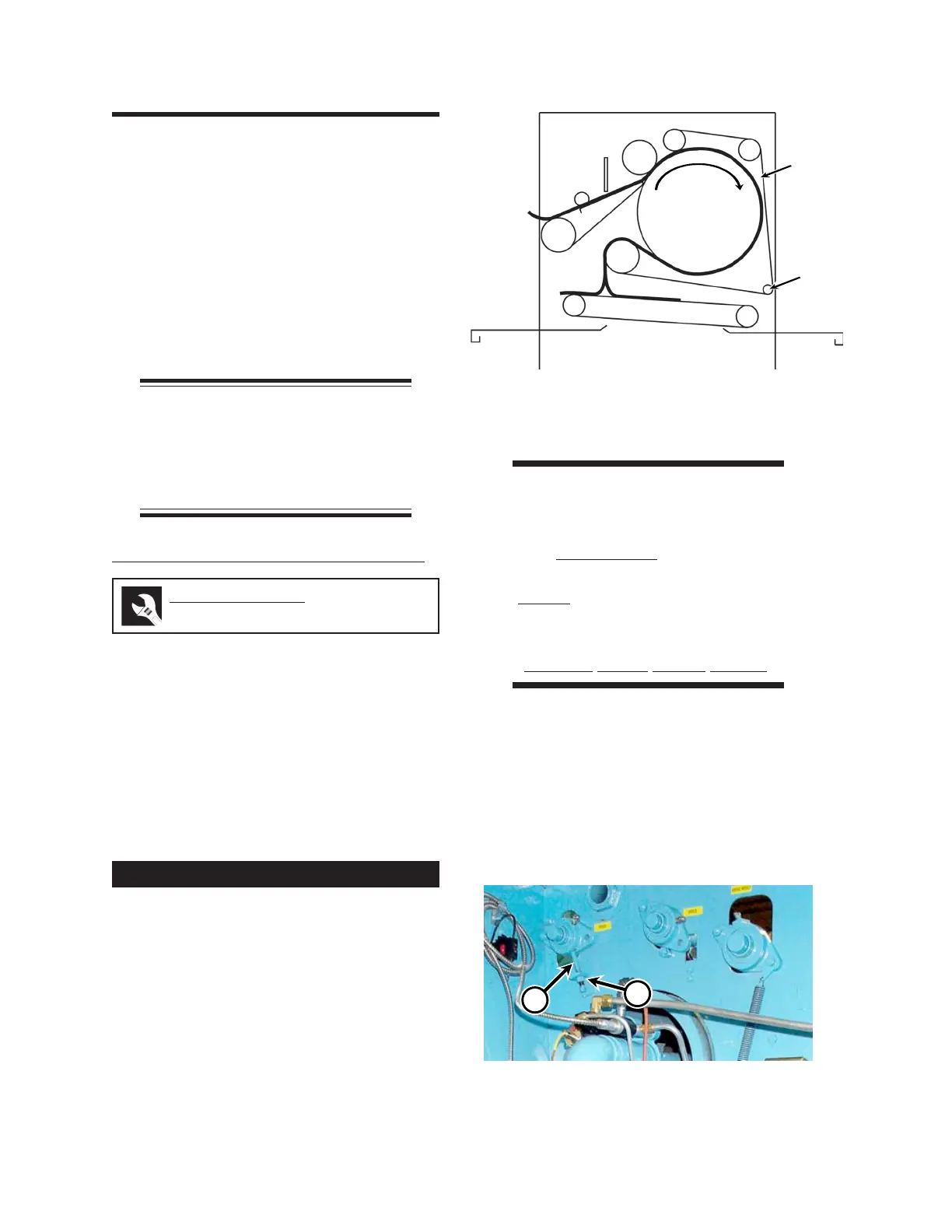

7.4 Return Section

Flatwork is directed through the ironing section

by the return section (Figure 7-12). The return

section consists of the following components:

• Return ribbons (A)

• Idler rolls (B)

• Return ribbon guide assembly (C)

• Return ribbon drive roll (D)

NOTE: Read the Pink

Operator Safety sheet,

RETURN RIBBON REPLACE-

MENT REMINDER located in the

front of this manual.

Return Ribbon Tension Adjustment

The tension of the return ribbons on the return

ribbon guide assembly needs to be adjusted when

the ribbons begin to sag. Chains and springs are

attached to each guide assembly bearing and are

anchored by adjustment screws.

When the return ribbons begin to sag, first make

sure the guide assembly is free to move. If that is

not the problem, the tension on the return ribbon

guide assembly must be adjusted.

1. Turn the power OFF at the main discon-

nect switch.

2. Open both end frame doors. The unit will

not operate while the safety interlock

switches are open. As a temporary mea-

sure during this procedure, defeat the

safety interlock switch in each end frame.

WARNING

The safety interlock switches

are only to be defeated

temporarily while the

procedure is being done.

Never operate the unit unless

all safety systems are

working correctly.

Serious Injury Could Result.

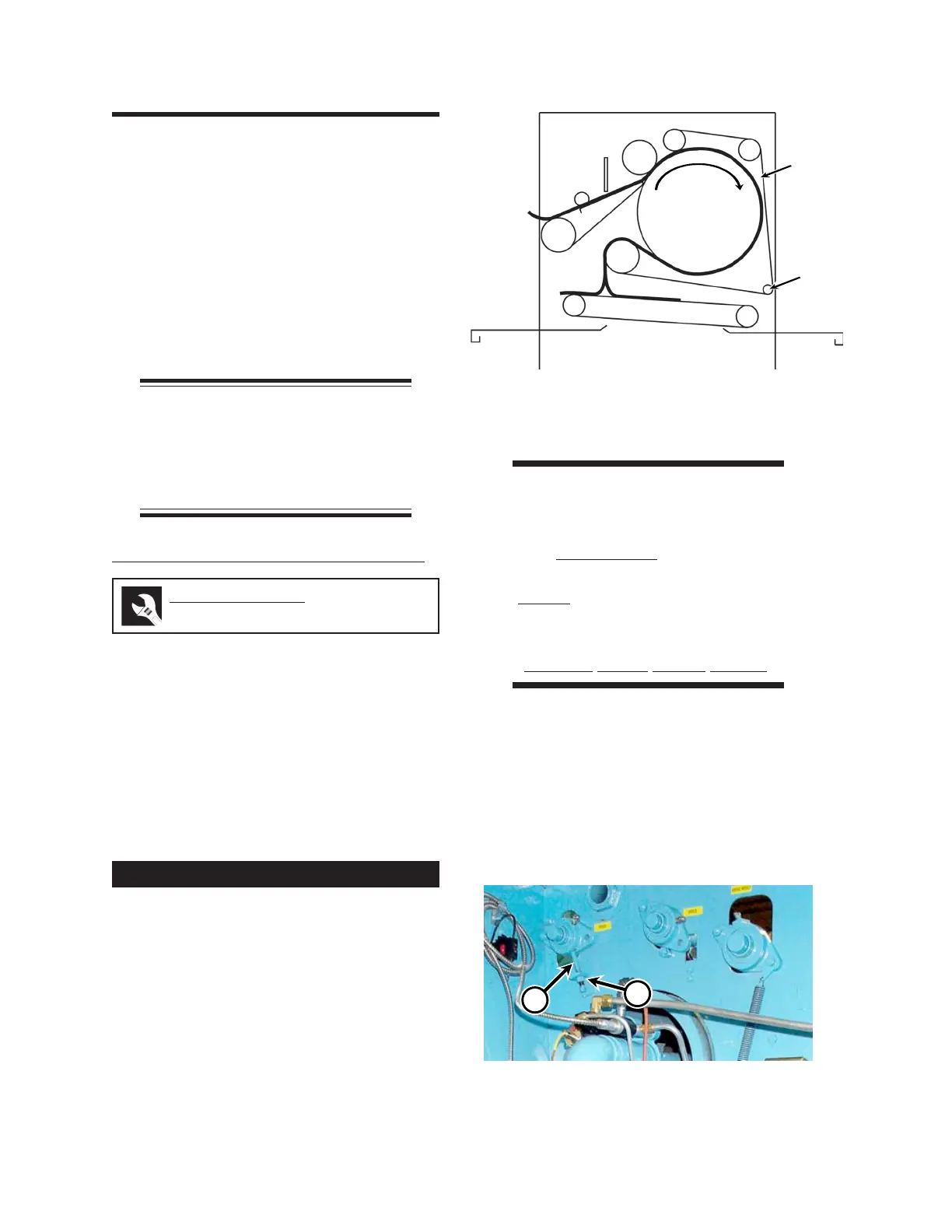

3. Locate the adjusting screws (Figure 7-13,

A) inside both end frames which secure

each return ribbon drive roll bearing in po-

sition. Loosen the locknuts (B), while

holding the screws in place, and adjust

each screw the same number of turns

clockwise until the ribbons are snug

against the drive roll.

Perform only when the unit is COOL.

Required Tools

wrench

Figure 7-12: The return ribbons and their drive

roll move the flatwork against the

ironing cylinder.

B

B

A

C

D

Ironing

Cylinder

Figure 7-13: The return ribbon guide assembly

adjustment screws (A) and locknuts

(B) are located inside each end frame.

B

Loading...

Loading...