Repair GL16

7-22

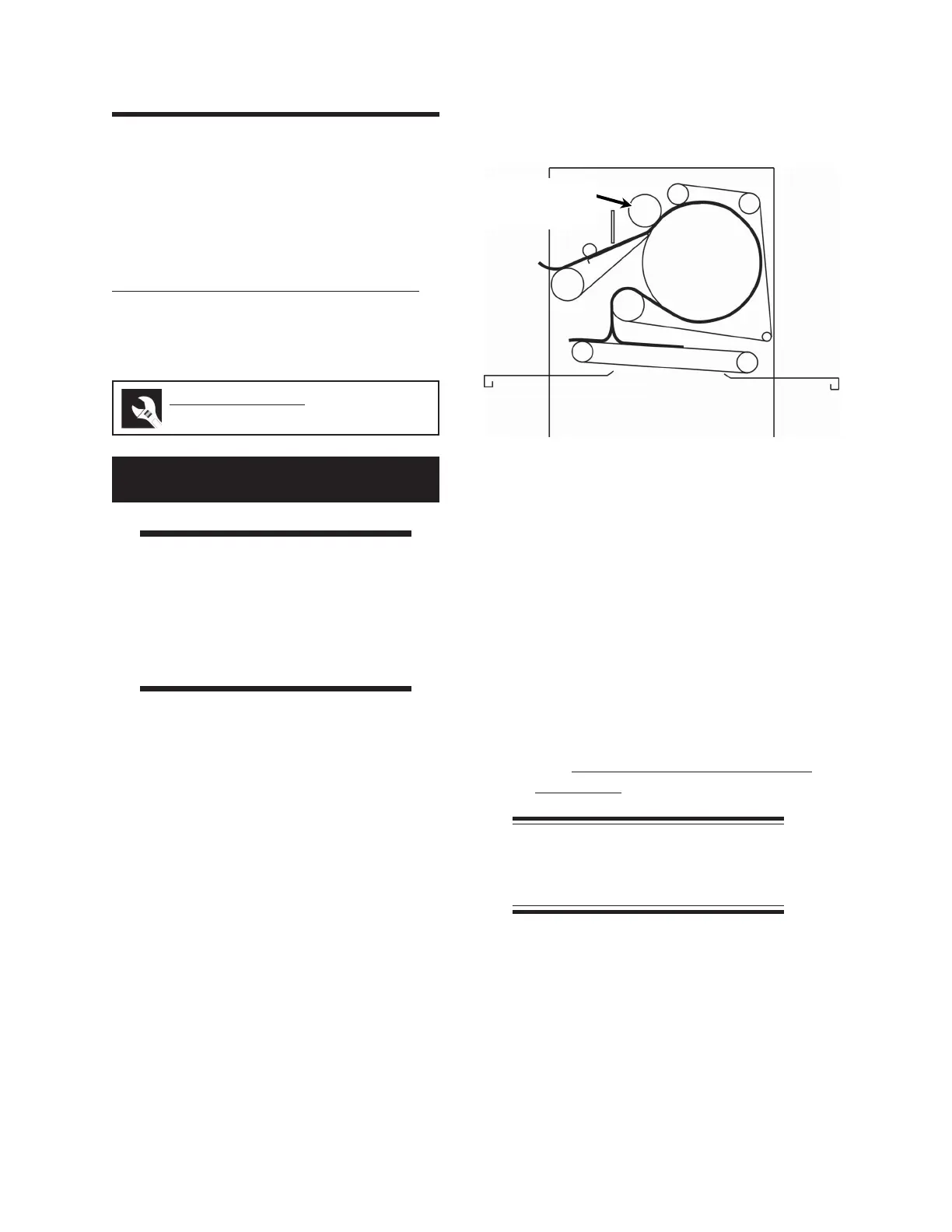

7.6 Compression Roll

The compression roll improves flatwork finish

(Figure 7-21). Over time, the tension on the

compression roll may need to be adjusted, and

the padding may have to be replaced.

Compression Roll Pressure Check

When flatwork does not feed into the ironing

section smoothly, the pressure of the compression

roll may need to be adjusted.

WARNING

Specific procedures that

require the unit to be

running should be done with

extreme caution and

attention to detail.

1. Cut a piece of brown packing paper ap-

proximately 9" wide and 3' long (230 mm

x 915 mm).

2. The unit should be completely cooled

down. Make sure that the compression

roll is engaged, the spring-loaded handles

are in their bracket slots in each end frame

(Figure 7-22), and the end frame doors

are closed.

3. Turn the power ON at the main discon-

nect switch.

4. Press the green START button. Turn the

SPEED knob to the slowest speed.

5. Feed the piece of paper into the ironing

section at one side. Immediately pull back

gently on the paper. You should feel the

compression roll pulling the paper into the

ironing section, but be able to pull back

the paper without tearing it.

6. Repeat this procedure along the length of

the unit. If there is uneven or no pressure

placed on the paper, the compression roll

pressure must be adjusted. For more in-

formation within this section, proceed to

the

Compression Roll Pressure

Adjustment procedure.

NOTE: Too little pressure in the

middle may indicate too much

pressure at the ends.

Perform only when the unit is OFF

(with power disconnected) and COOL.

Required Tools

utility knife, brown packing paper

Figure 7-21: The compression roll helps to move

the flatwork into the ironing section.

Compression

Roll

Loading...

Loading...