GL16 Repair

7-41

Burner Tip Maintenance

1. Remove the burner. For more informa-

tion within this section, go back to the

Burner Removal procedure.

2. Place the burner assembly on a sturdy

worktable.

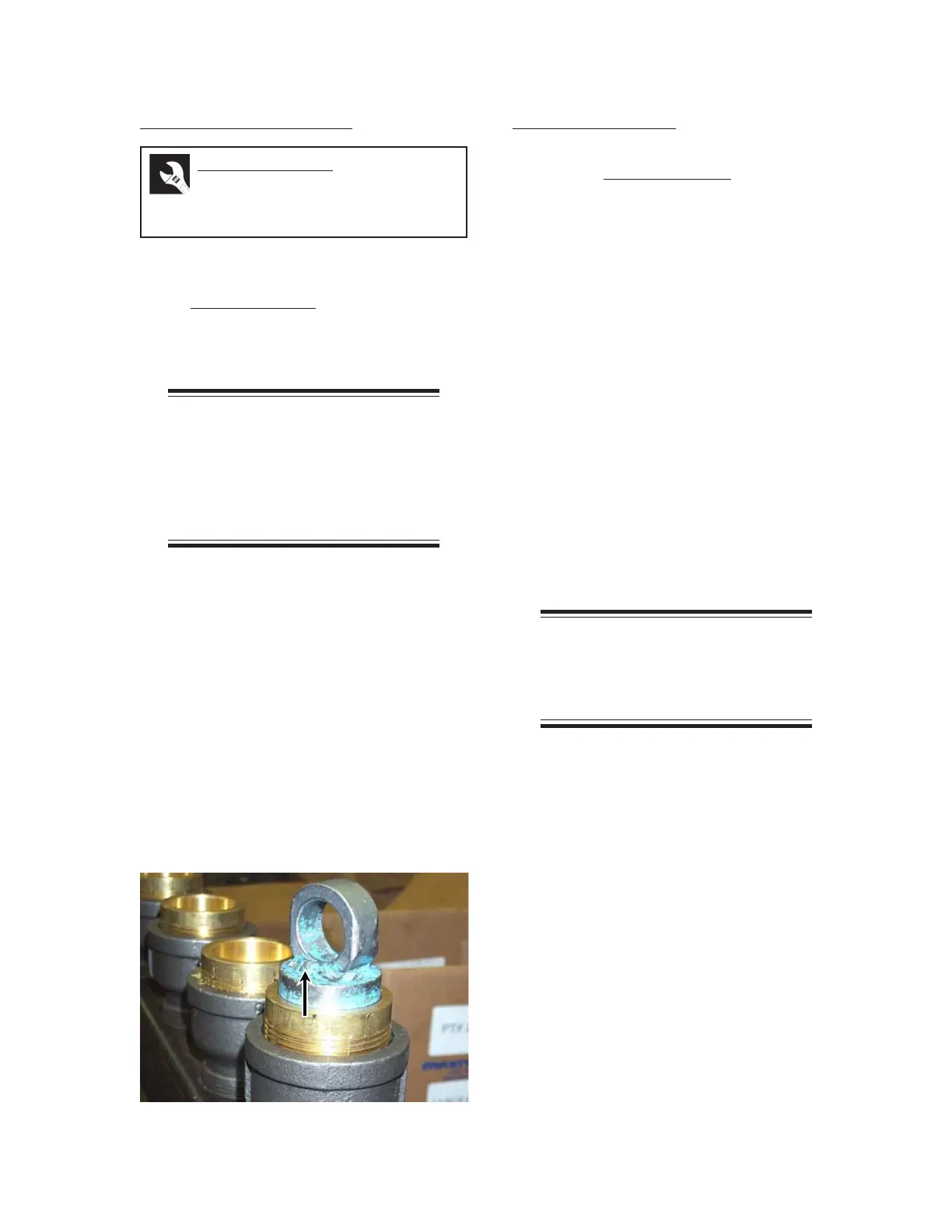

NOTE: To prevent distortion of

the burner tips, it is necessary to

insert a short, round steel shaft or

bar into the top of the burner tip

that just fits and can be easily

removed.

3. Place a steel insert with a diameter of

1.490" ± 0.005" (37.85 mm ± 0.13 mm)

into the first burner tip (Figure 7-40) so

the tip does not bend or get stripped. Use

a chain wrench to remove the burner tip.

Repeat this process for the remaining

burner tips.

4. Blow out each tip with compressed air

from the top and bottom.

5. Use compressed air to blow out the burner.

6. Install each burner tip using the steel in-

sert and chain wrench.

Burner Installation

To reinstall the burner assembly, reverse the

steps in the Burner Removal procedure and

refer to the following additional guidelines:

• When the assembly has been pushed

back into the ironing cylinder, use the 1" x

4' (25 mm x 1220 mm) pipe to help guide

the tail pipe into place. With two people

at the left end frame pushing down

slightly on the burner assembly, a third

person needs to reach into the ironing

cylinder from the right end frame to pull

the end of the pipe over the tail pipe.

• Once the tail pipe is seated in the

1" x 4' (25 mm x 1220 mm) pipe, lift up

the burner assembly at the left end frame

and slide it the rest of the way into

position. Remove the pipe and finish

installing the burner assembly.

• After the burner is installed, start the unit

to verify proper operation.

NOTE: If the gas pressure

needs to be adjusted, go back to

the INSTALLATION chapter, Gas

Connection Checkout section.

Required Tools

chain wrench, steel insert with

a diameter of 1.490" ± 0.005"

(37.85 mm ± 0.13 mm)

Figure 7-41: Prevent burner tip distortion with a

steel insert.

Loading...

Loading...