GL16 Preventive Maintenance

4-3

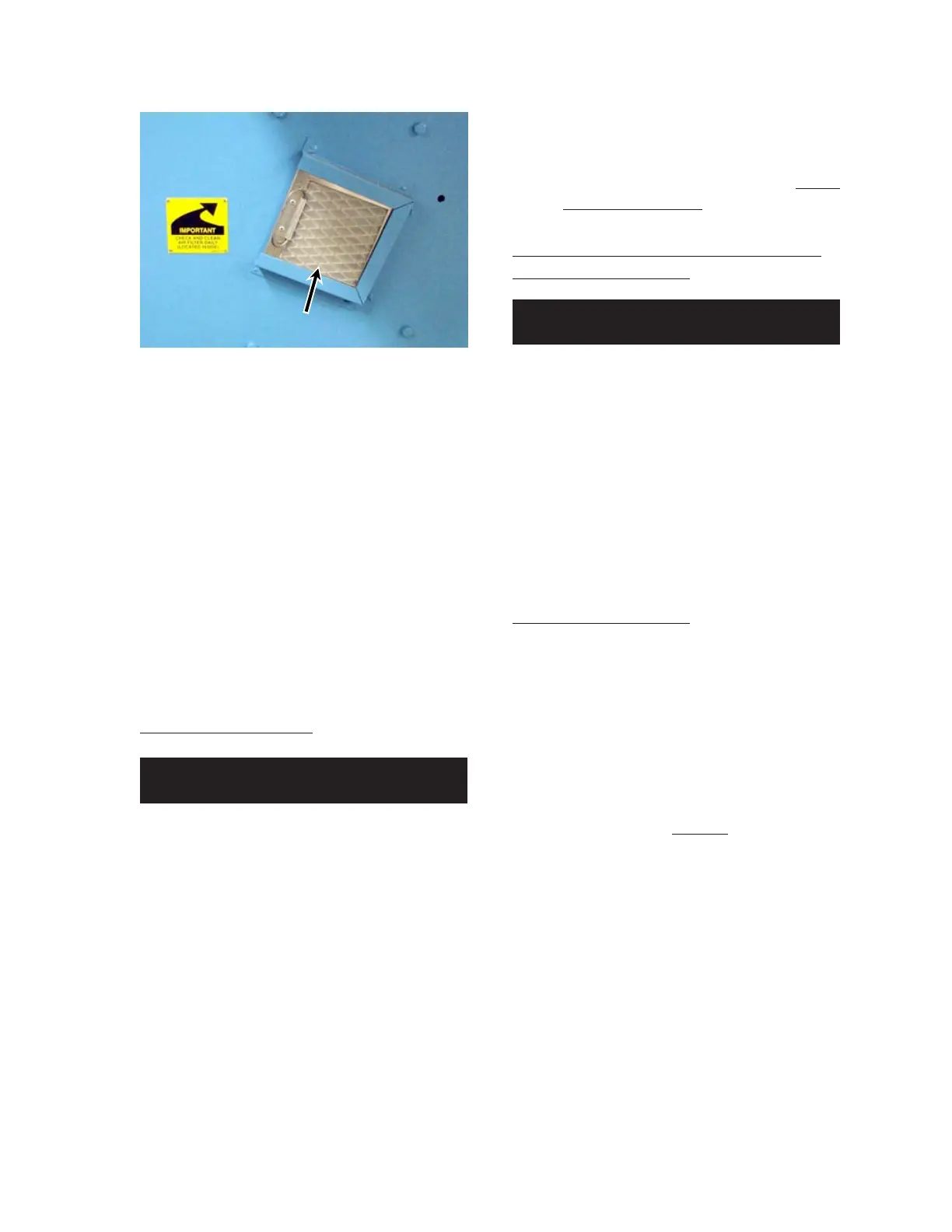

3. Remove the combustion blower air filter

(Figure 4-1).

4. Blow out the filter with compressed air,

against the direction of the air flow ar-

row, or soak the filters in a mild detergent

and water solution.

5. Install the combustion air filter. Make sure

the filter is installed with the handle to-

wards the outside of the filter housing.

6. Close and secure the left end frame door.

Check Guide Tapes

Guide tapes are used to prevent flatwork from

sticking to the compression roll which can result

in jams.

1. Turn the power OFF at the main discon-

nect switch.

2. Inspect for broken or missing guide tapes

and for wear or fraying of the edges.

3. Make sure the ends of the guide tapes

are properly stapled together.

4. Replace any guide tapes that are dam-

aged, broken, or missing. For more infor-

mation within this manual, proceed to the

REPAIR chapter, Feed Section,

Guide

Tape Replacement procedure.

Check Red STOP Buttons and Red

Safety Finger Guard

The unit should never be operated without all

safety guards in place. Check that all four red

STOP buttons, and the red safety finger guard,

bring the entire unit operation to a halt.

Repair any faulty safety devices before

operating the unit.

For more information on safety features refer

back to the OPERATING GUIDELINES

chapter, Safety Features section.

Wax Ironing Section

Daily waxing of the ironing section is necessary

to produce a finer flatwork finish, to prolong return

ribbon life, and to prevent the flatwork from

sticking to the ironing cylinder.

For more information on detailed waxing

instructions, go back to the OPERATING

GUIDELINES chapter, Daily Operating

Procedures section,

Waxing procedure.

Figure 4-1: The air filter for the combustion

blower motor is located on the left

end frame.

Perform only when the unit is OFF

(with power disconnected) and COOL.

Perform only when the unit is

RUNNING and COOL.

Loading...

Loading...