GL16 Installation

2-15

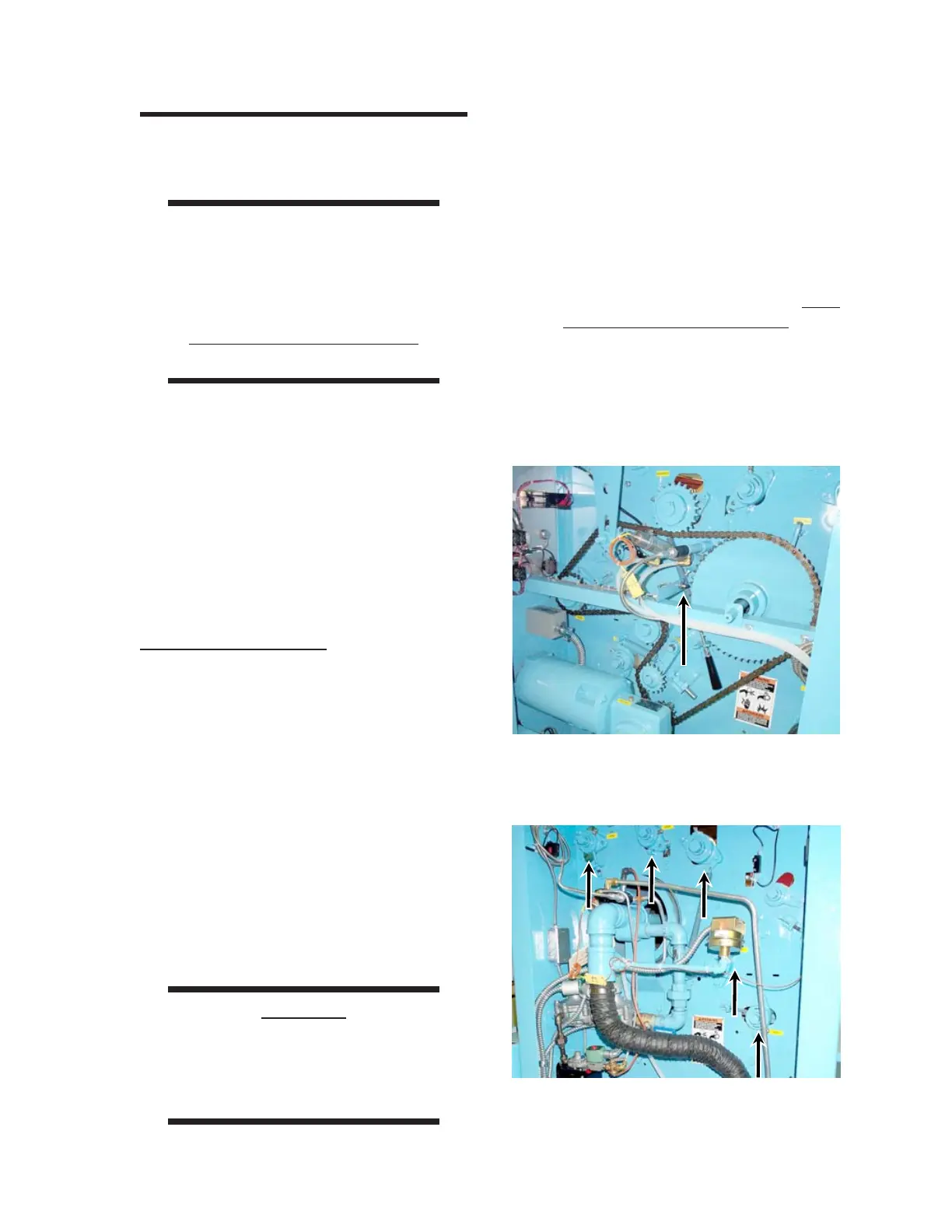

Figure 2-21: The machine speed sensor must be

correctly positioned near the teeth of

the ironing cylinder sprocket.

2.3 Pre-Operational

Checkout

WARNING

Understand the OPERATING

GUIDELINES chapter,

Operating Controls section

before starting any of the

Pre-Operational Checkout

procedures.

Before the unit can be placed into full operation,

perform the following procedures:

• Security of Hardware

• Electrical Connection Checkout

• Control Function Checkout

• Gas Connection Checkout

• Checkout Completion

Security of Hardware

1. Open the doors on both end frames.

2. The machine speed sensor is located in

the right end frame (Figure 2-21). It is

mounted on a bracket very close to the

teeth of the ironing cylinder sprocket. The

unit starts but will shut down after 5 sec-

onds if this sensor has moved from the

correct position. Check that the sensor is

0.06" (1.5 mm) from the teeth of the

sprocket. For information within this

manual on adjusting the position of the

sensor, proceed to the REPAIR chapter,

Machine Speed Sensor Adjustment

section.

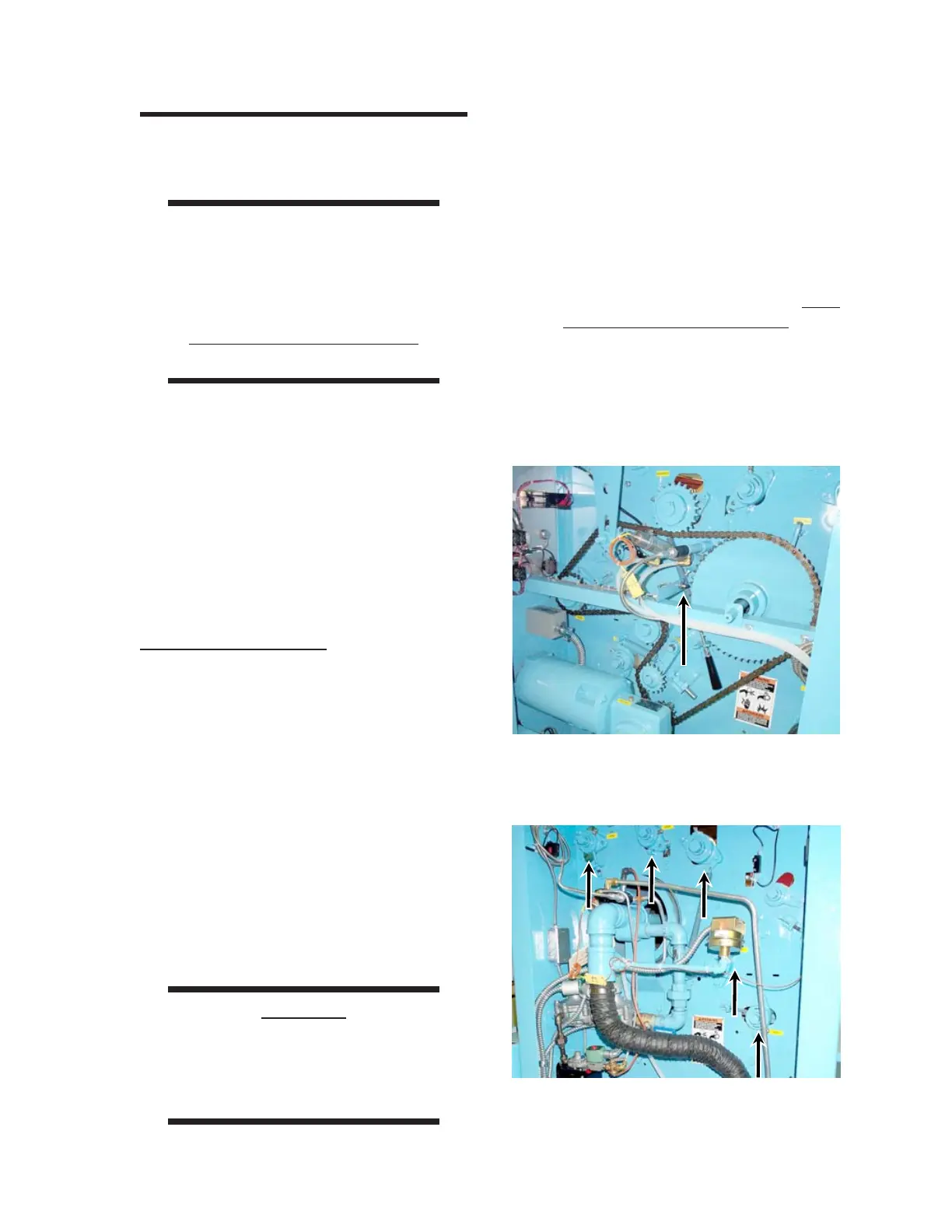

CAUTION

Do NOT put setscrews into

the left end frame bearings—

this allows for heat

expansion (Figure 2-22).

3. Check all hardware connections and

tighten as necessary. Check that all set-

screws are sufficiently tightened to hold

their respective components in position.

4. Make sure all protective wrappers and

wooden wedges holding the ironing cylin-

der are removed. For more information

within this chapter, go back to the

Installation Procedures section,

Final

Protective Wrapper Removal proce-

dure.

5. Close and secure both end frames.

Figure 2-22: Do NOT put setscrews into left end

frame bearings.

Loading...

Loading...