Preventive Maintenance GL16

4-4

1. Turn the power ON at the main discon-

nect switch.

2. Press the green START button.

3. Check all ribbons for proper placement,

tracking, tension (no visual sagging), and

general condition (smoothness, scorching,

fraying, and tears).

4. For more information on adjusting, repair-

ing and replacing various ribbons within

this manual, proceed to the REPAIR

chapter.

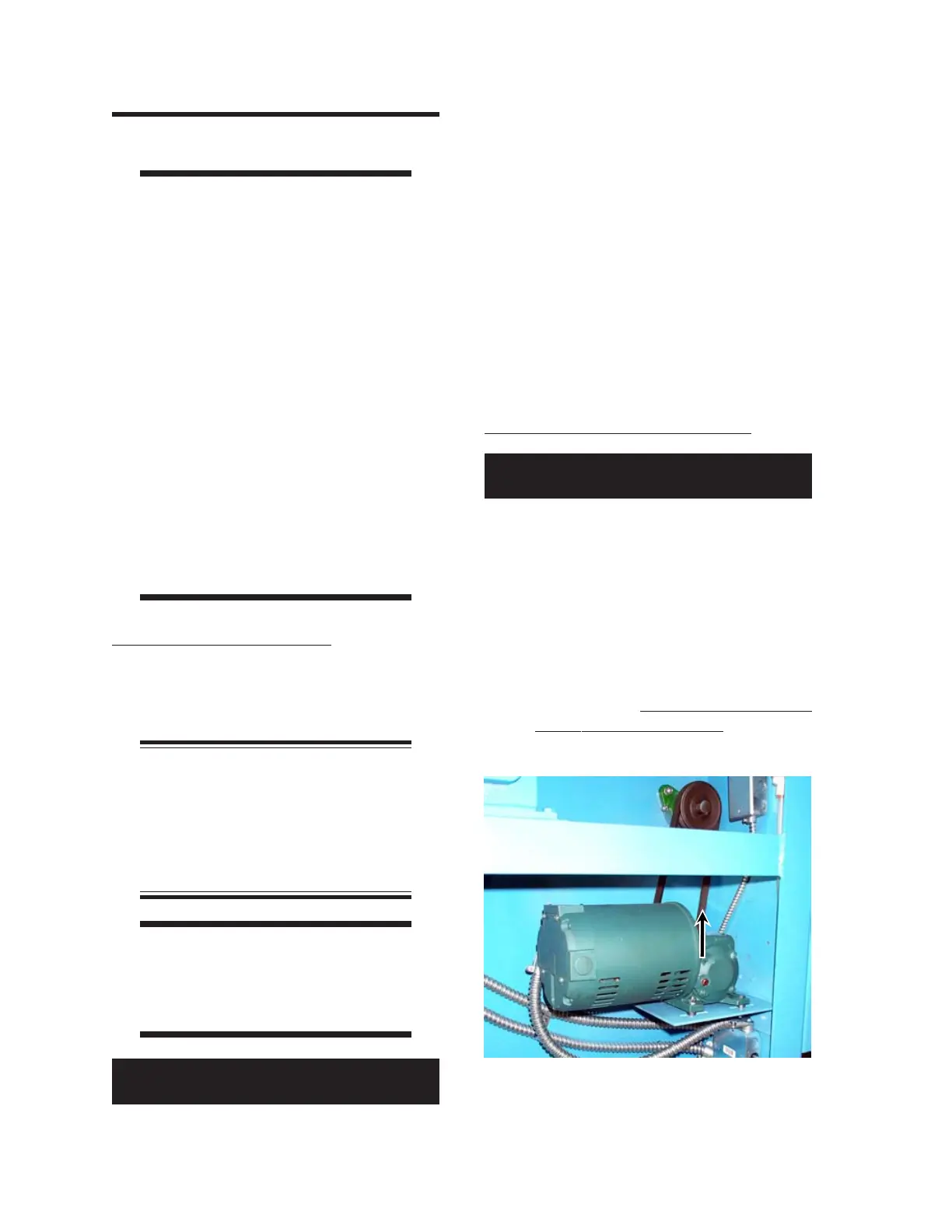

Check Drive Belt (Type R Unit)

1. Open the right end frame.

2. Examine the condition of the delivery drive

belt. Check the belt for general wear, fray-

ing and tension (Figure 4-2).

3. For information within this manual on ad-

justing the belt tension, proceed to the

REPAIR chapter, Delivery Section—

Type R Unit,

Delivery Section Drive

Belt Tension Adjustment procedure.

4.2 Weekly PM

WARNING

Do not repair or correct any

of these conditions without

reading and understanding

the REPAIR chapter

of this manual.

Only QUALIFIED

PERSONNEL should

troubleshoot and

repair this unit.

Make sure that the machine

is completely cooled down

and that power is

disconnected at the

disconnect switch before

servicing the unit.

Check Ribbon Condition

Preshrunk canvas is used for the feed ribbons

and delivery ribbons. High temperature synthetic

material is used for the return ribbons.

NOTE: Ribbons that break

should be replaced immediately.

Return ribbons move and hold the

flatwork in proper contact with the

heated cylinder, ensuring quality

flatwork finish.

WARNING

Never touch any part of the

unit while it is moving.

Serious injury could result.

Perform only when the unit is

RUNNING and COOL.

Perform only when the unit is OFF

(with power disconnected).

Figure 4-2: The delivery drive belt is located in

the right end frame (type R units).

Loading...

Loading...