Operating Principles GL16

5-6

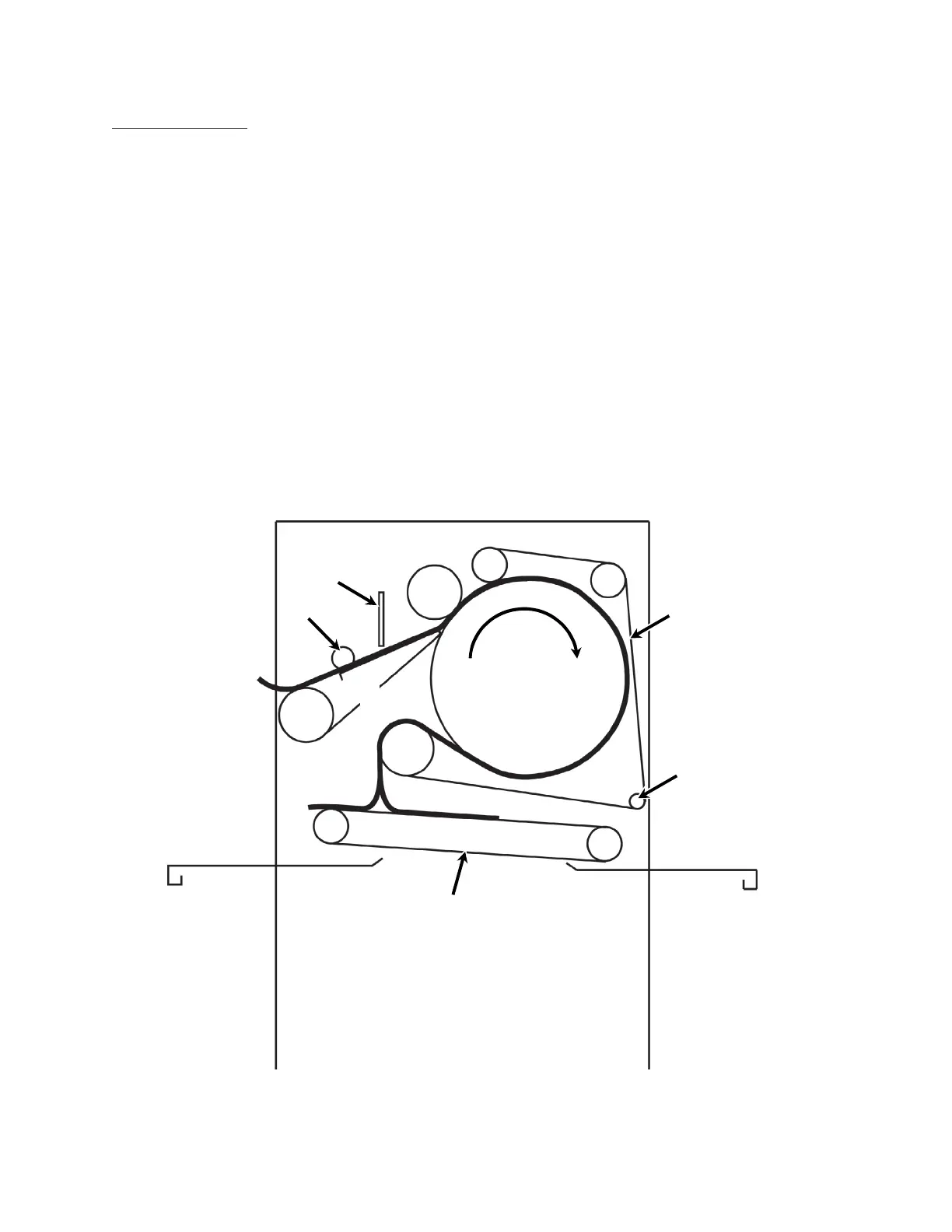

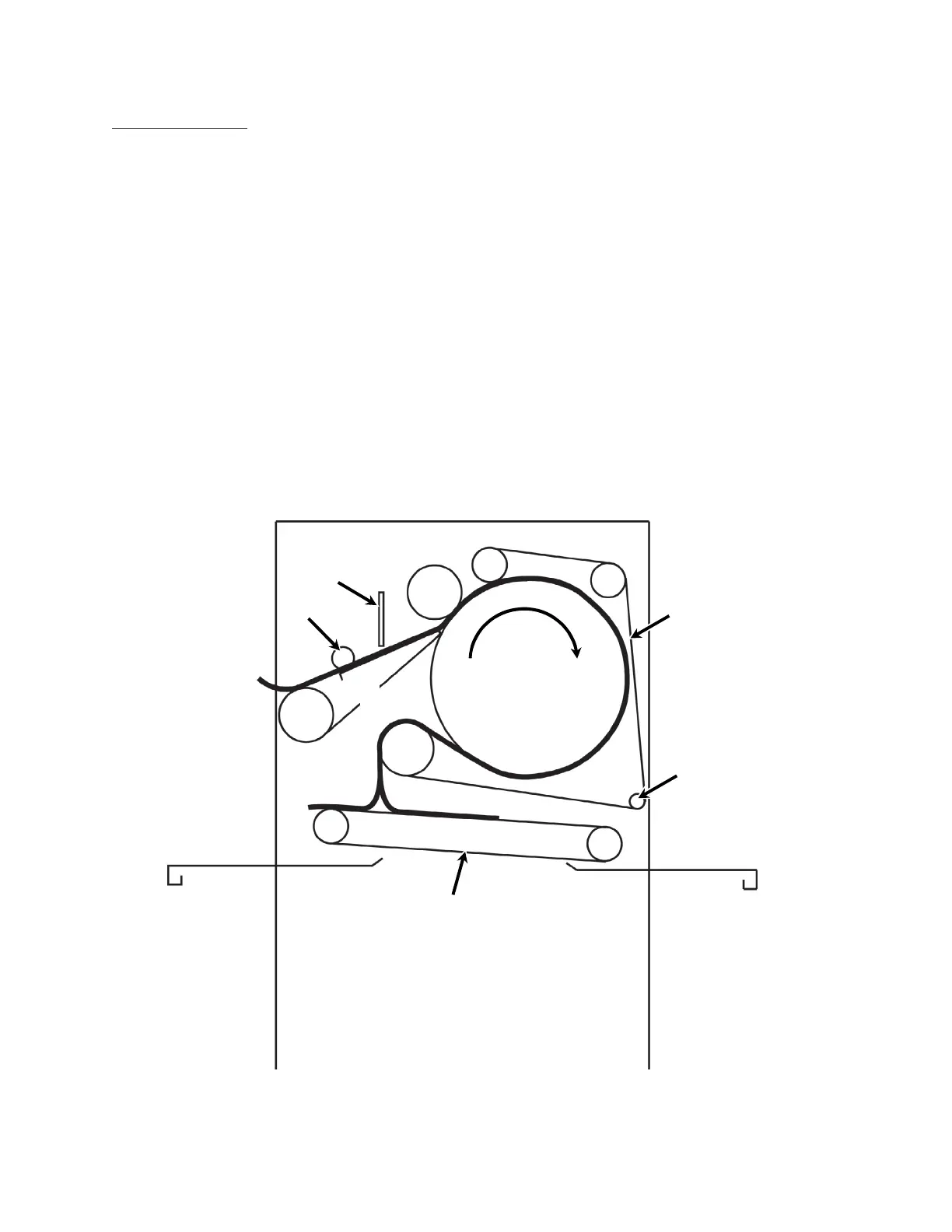

Ironing Section

The other components of the mechanical

system are the rolls and ribbons which move the

flatwork through the unit. Use the cross-section

below (Figure 5-4) to follow the path of the

flatwork. Note the function of each roll and set

of ribbons as the flatwork moves through the unit.

Flatwork Path—Type F and R Units

1. Feed ribbon drive roll (A) rotates the set

of feed ribbons (B).

2. Feed ribbons (B) move the flatwork under

the doffer roll (C) and the safety finger

guard (D) toward the ironing cylinder (F).

3. Flatwork is then carried under the spring-

tensioned compression roll (E), which

smooths and flattens the flatwork.

4. To keep the flatwork tight against the iron-

ing cylinder (F), a set of return ribbons

(G) is rotated by the return ribbon drive

roll (H) and guided by the return ribbon

guide assembly (K) and the idler rolls (J).

Flatwork Delivery Path—Type R Unit

Delivery ribbons (L) are rotated by the delivery

drive roll (M) and idler roll (N).

The delivery drive motor is reversible, and the

delivery ribbons can discharge the flatwork to the

front or rear of the unit.

Figure 5-4: Cross-section of mechanical components. The flatwork path

through the ironing section is indicated by the bold line.

A

L

H

N

M

K

C

D

E

F

Ironing

Cylinder

J

J

G

B

Loading...

Loading...