Repair GL16

7-16

5. Pull the return ribbons around their tracks

until all the lacing clips are accessible and

aligned at the front of the unit. Remove

all the connecting pins from the return rib-

bons. Position the return ribbons away

from the drive roll.

6. Place a tarp, plastic drop cloth, heavy

paper, or another temporary protective

covering over the delivery ribbons and re-

ceiving shelf.

7. Remove the screws and clamps at each

end of the drive roll (Figure 7-15) that hold

the friction material in place. Set the

clamps aside for later use.

8. Pull or cut off the old return ribbon drive

roll friction material.

9. Remove old cement from the drive roll

with a scraper, coarse sandpaper, or a steel

brush. Wipe away remaining residue with

a clean cloth.

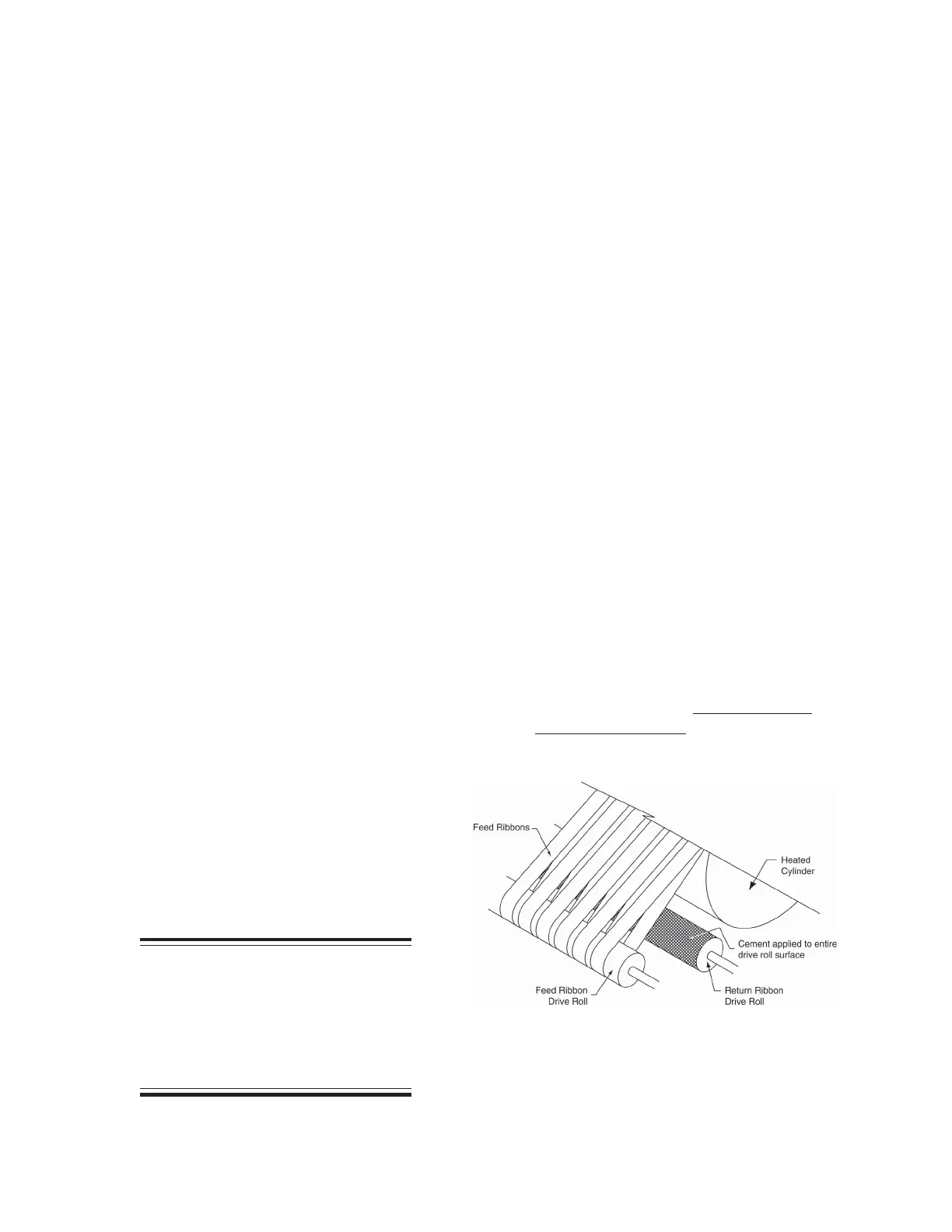

10. Apply new cement evenly along the full

length of the drive roll and smooth with a

putty knife over the entire surface of the

drive roll (Figure 7-16).

11. Secure the friction material at one end of

the roll with masking tape so it does not

unwind during installation.

12. Carefully spiral-wind the friction material

around the length of the drive roll. This

procedure is easier with two people. One

person turns the drive roll by hand while a

second person holds the roll of material

and guides the material onto the drive roll,

pressing it firmly into place.

NOTE: The drive roll friction

material should be spiral-wound at

about a 45° angle. A more vertical

angle will use more cover material.

A more horizontal angle will use

less cover material.

13. Trim the ends of the friction material so it

is even with the end of the drive roll. Use

a nail to make a hole in the material where

the screws go through for the clamps. In-

stall the end clamps and screws.

14. Remove the temporary protective cover-

ing and clean up the area.

15. Refasten the return ribbons. Stagger the

positions of the lacing clips to give the flat-

work a smooth flow.

16. Remove the wooden wedges at the guide

assembly ends, or untie from above to put

tension back on the return ribbons.

17. Place the main drive chain on the sprock-

ets and, using a chain puller, bring the ends

close enough together to attach the clips.

If necessary, adjust the tension of the

chain. For more information within this

chapter, proceed to the Drive Chain sec-

tion.

18. Allow the cement to harden for 5 to 6

hours before operating the unit.

19. After the cement hardens, adjust the rib-

bons. For more information within this sec-

tion, go back to the

Return Ribbon

Tension Adjustment procedure.

Figure 7-16: Cement secures the friction material

to the return ribbon drive roll.

Loading...

Loading...