Installation GL16

2-12

Required Tools

wrench, pipe joint compound

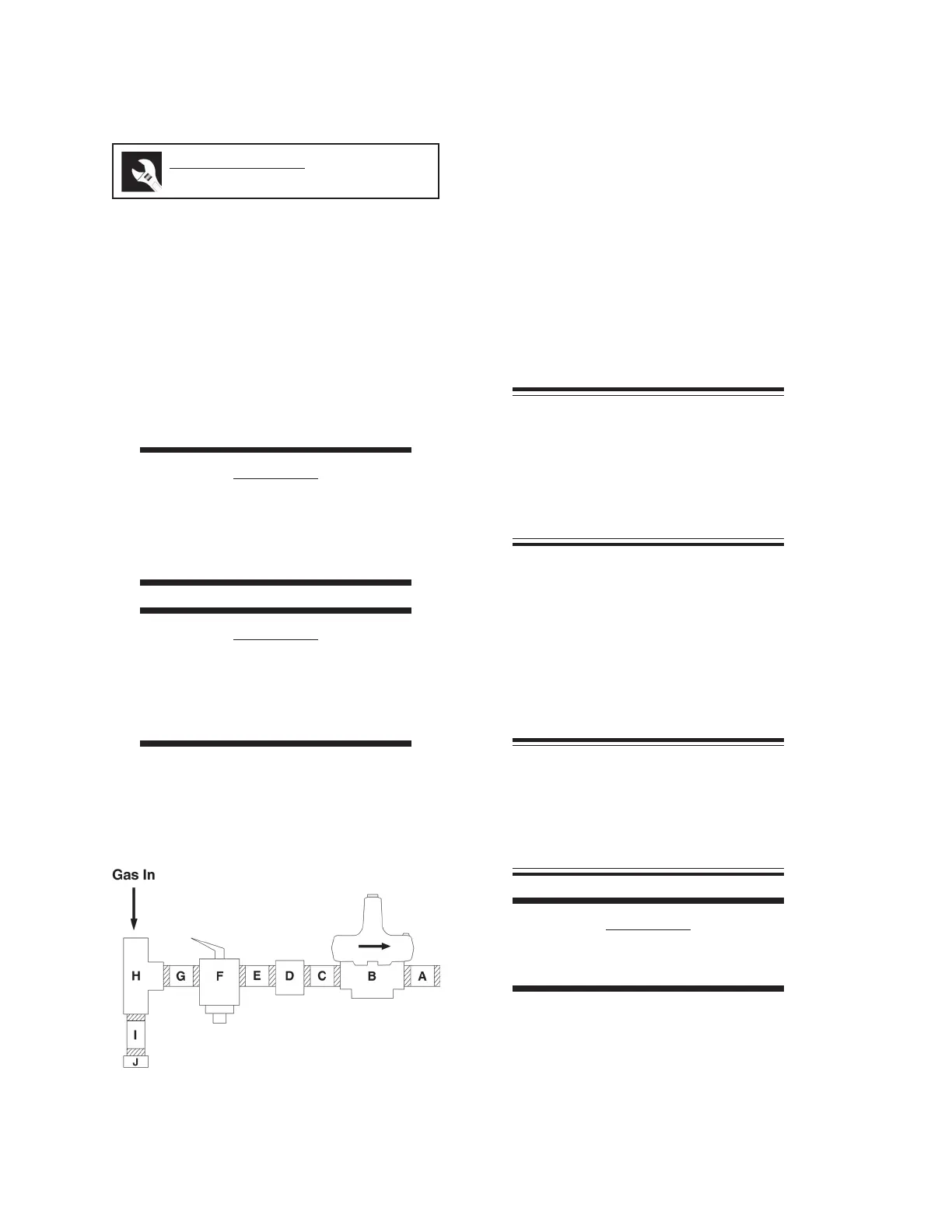

Figure 2-18: Install the hardware for the gas

connection as shown.

Regulator and Valve Installation

The gas line to the unit should be routed so it

does not interfere with any service panel or block

access to the back of the unit.

1. Check all internal gas connections in the

unit. Tighten any unions that became loose

during shipment.

2. Connect the short nipple (Figure 2-18, A)

to the coupling at the back of the left end

frame.

CAUTION

The regulator must be

installed so the gas flow is in

the direction of the arrow on

the regulator.

CAUTION

The regulator must not be

installed upside down.

The regulator must be

installed horizontally.

3. Carefully note the direction of the arrow

on the regulator (B). At the point of the

arrow, connect the discharge side of the

regulator to the short nipple (A).

4. Connect a short nipple (C) to the inlet of

the regulator (B). Connect the female half

of union (D) to the short nipple (C).

5. Connect short nipples (E and G) on either

side of gas valve (F). Connect the male

half of union (D) to one of the nipples

(E or G), and connect the branch of tee

(H) to the other nipple. Install the tee ver-

tically.

6. Attach a dirt leg nipple (I) with a cap (J)

to the lower run of the tee (H).

NOTE: A dirt leg in the gas line

upstream of the gas pressure

regulator helps prevent

malfunctions resulting from rust,

grit, dirt, and other solid particles

in the gas supply.

7. Connect the two halves of union (D).

8. Make sure the manual gas valve (F) is

closed, by rotating the handle to a 90° angle

from the length of the gas pipe.

9. Extend the gas supply line to the top of

the tee (H).

NOTE: If possible, extend the

gas supply line directly from the

gas meter to the unit without any

other equipment connected to this

line.

CAUTION

Do not open any gas valves

at this time.

Loading...

Loading...