SET-UP AND INSTALLATION TMS9000-2 OPERATOR MANUAL

6-34

Published 02-21-2019, Control # 611-05

labeled with the same size and rope diameter as the rope

end clamp.

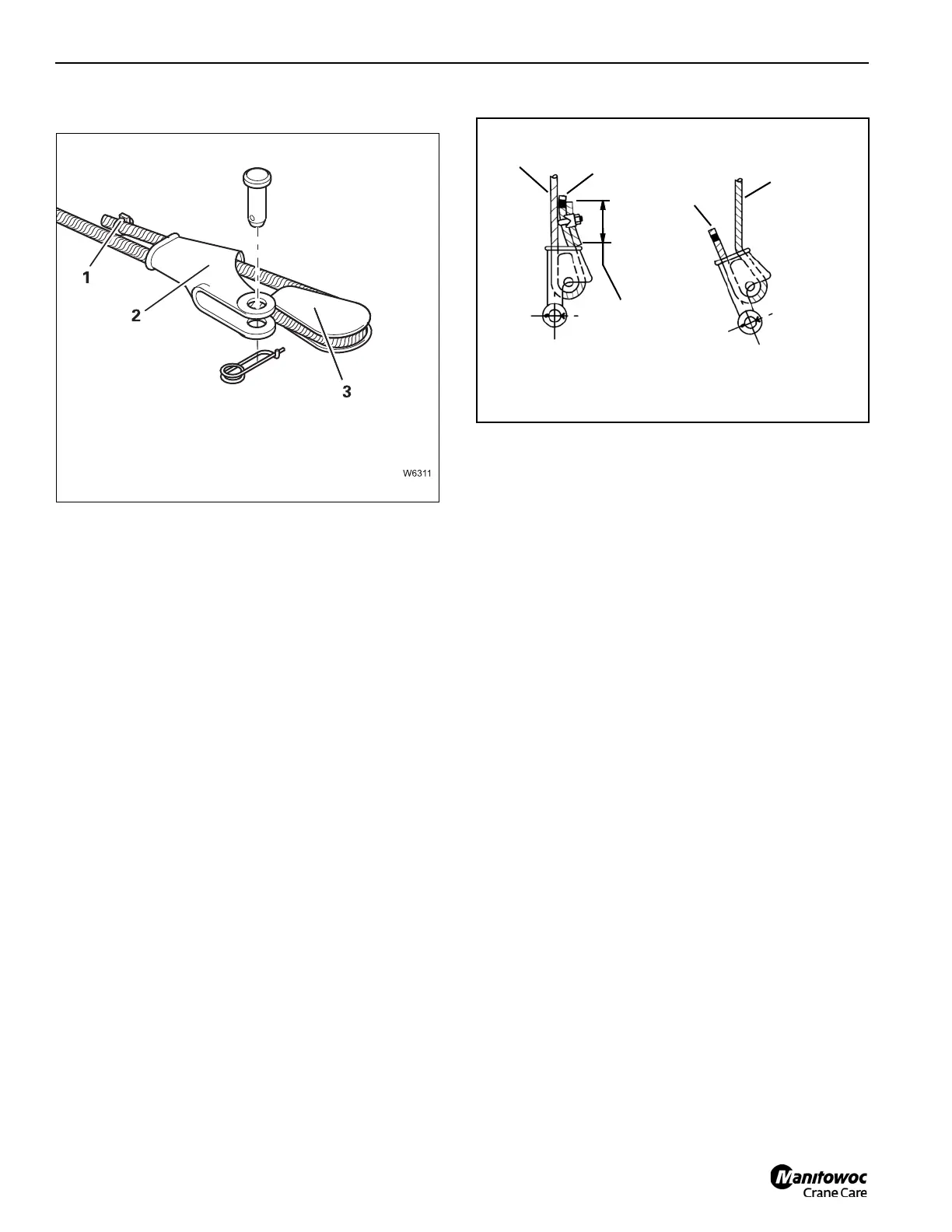

Attaching the rope end clamp

• Insert the hoist rope and rope wedge (3) into the rope

end clamp (2).

• Secure the rope clamp (1) to the loose end of the rope.

The rope clamp provides additional safety and prevents the

hoist rope from slipping out of the rope end clamp.

• Pull the rope end taut until the hoist rope fits snugly in

the rope end clamp.

1. Inspect the wedge and socket. Remove any rough

edges and burrs.

2. The end of the wire rope should be seized using soft, or

annealed wire or strand. If the end of the rope is welded,

the welded end should be cut off. Do not weld on size

6X37 rope. This will allow the distortion of the rope

strands, caused by the bend around the wedge, to

adjust themselves at the end of the line. Refer to

SECTION 1 - INTRODUCTION in the Service Manual

for wire rope procedures.

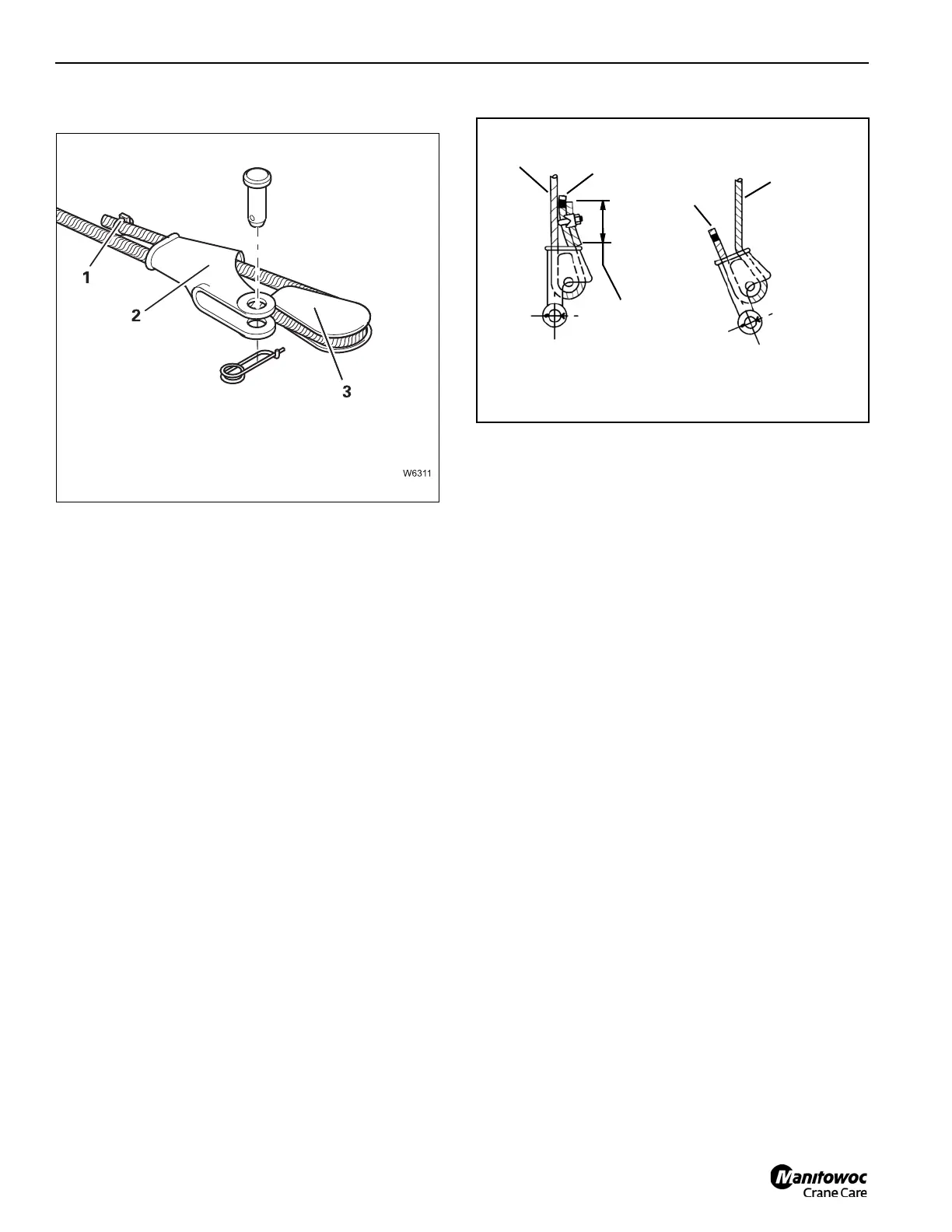

3. Make sure the live-end (Figure 6-51) of the rope is

directly in line with the ears of the socket and the

direction of pull to which the rope will be subjected. If the

rope is loaded into the socket incorrectly, under a load

the rope will bend as it leaves the socket, and the edge

of the socket will wear into the rope causing damage to

the rope and eventual failure.

.

4. Insert the end of the wire rope into the socket, form a

loop in the rope, and route the rope back through the

socket allowing the dead-end (Figure 6-51) to protrude

from the socket. Ensure the dead-end of the rope is of

sufficient length to apply end treatment to the dead-end

after the wedge has been seated.

5. Insert the wedge into the loop and pull the live-end of the

rope until the wedge and rope are snug inside the

socket. It is recommended that the wedge be seated

inside the socket to properly secure the wire rope by

using the crane’s hoist to first apply a light load to the

live-end.

6. After final pin connections are made, increase the loads

gradually until the wedge is properly seated.

7. The wire rope and wedge must be properly secured

inside the socket before placing the crane into lifting

service. It is the wedge that secures the wire rope inside

the socket. The dead-end treatment is used to restrain

the wedge from becoming dislodged from the socket

should the rope suddenly become unloaded due to the

headache ball or hook block striking the ground, etc;

refer to Dead-end Rigging, below.

Dead-end Rigging

Sketches A through F (Figure 6-52) illustrate various ANSI

approved methods for treating the dead-ends of wire ropes

which exit a wedge socket assembly. While use of the loop-

back method is acceptable, care must be exercised to avoid

the loop becoming entangled with tree branches and other

components during crane transport and with the anti-two

block system and other components during use of the crane.

Of the methods shown below, Grove prefers that method A

or F be used, i.e., clipping a short piece of wire rope to the

dead-end or using a commercially available specialty wedge.

Typically, it is recommended that the tail length of the dead-

end should be a minimum of 6 rope diameters but not less

Dead

End

Dead

End

Live End is

Entering

Wrong Side

Live

End

20 x Cable Dia

Minimum

RIGHT

WRONG

FIGURE 6-51

Wedge Socket

Loading...

Loading...