LUBRICATION TMS9000-2 OPERATOR MANUAL

5-24

Published 02-21-2019, Control # 611-05

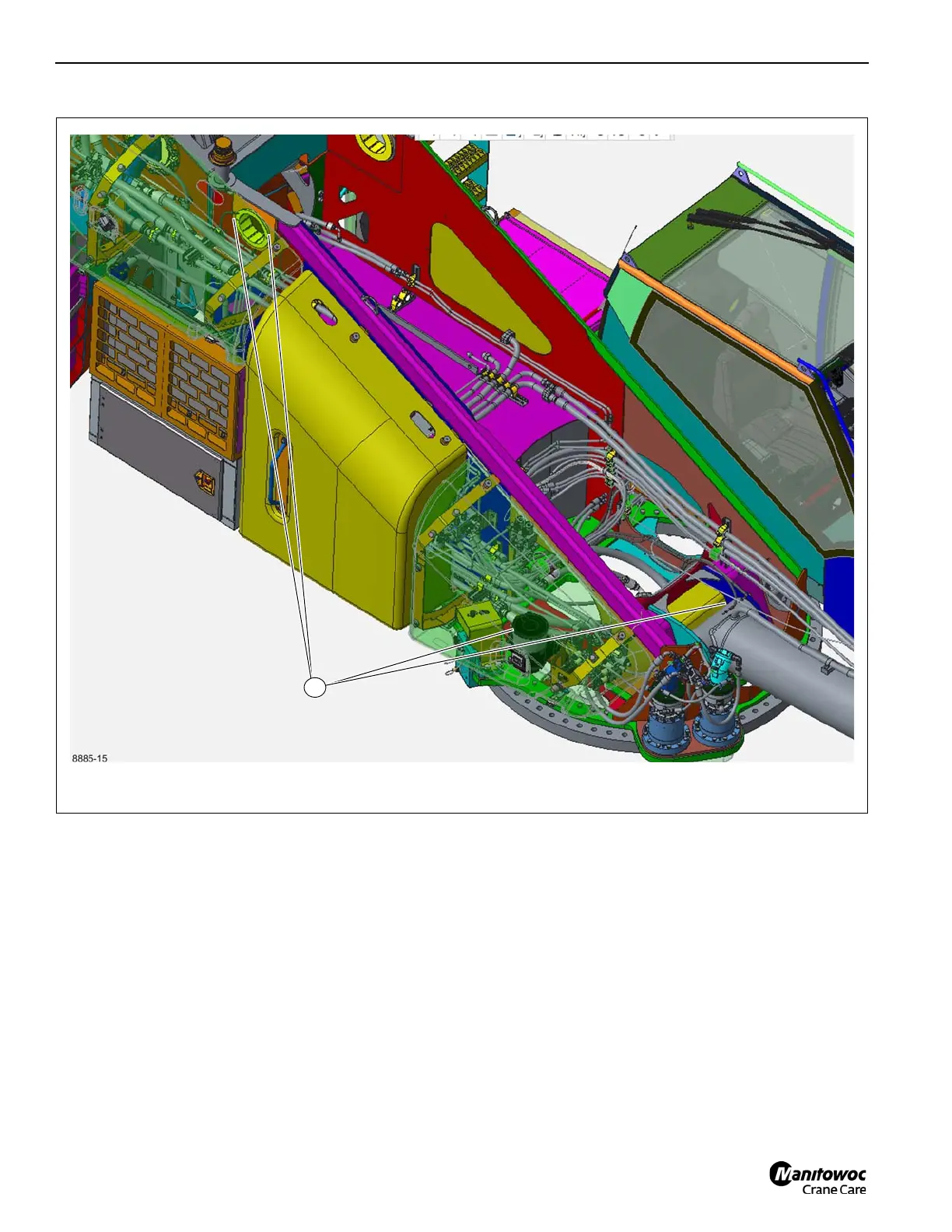

Boom Lubrication

Crane Setup

• Machine to be set up on firm level surface with fully

extended outriggers and a minimum of 22,000 lbs

counterweight installed. Make sure that the crane is

level.

• Boom must be directly over the front and the house lock

engaged.

• Set boom angle at zero degrees.

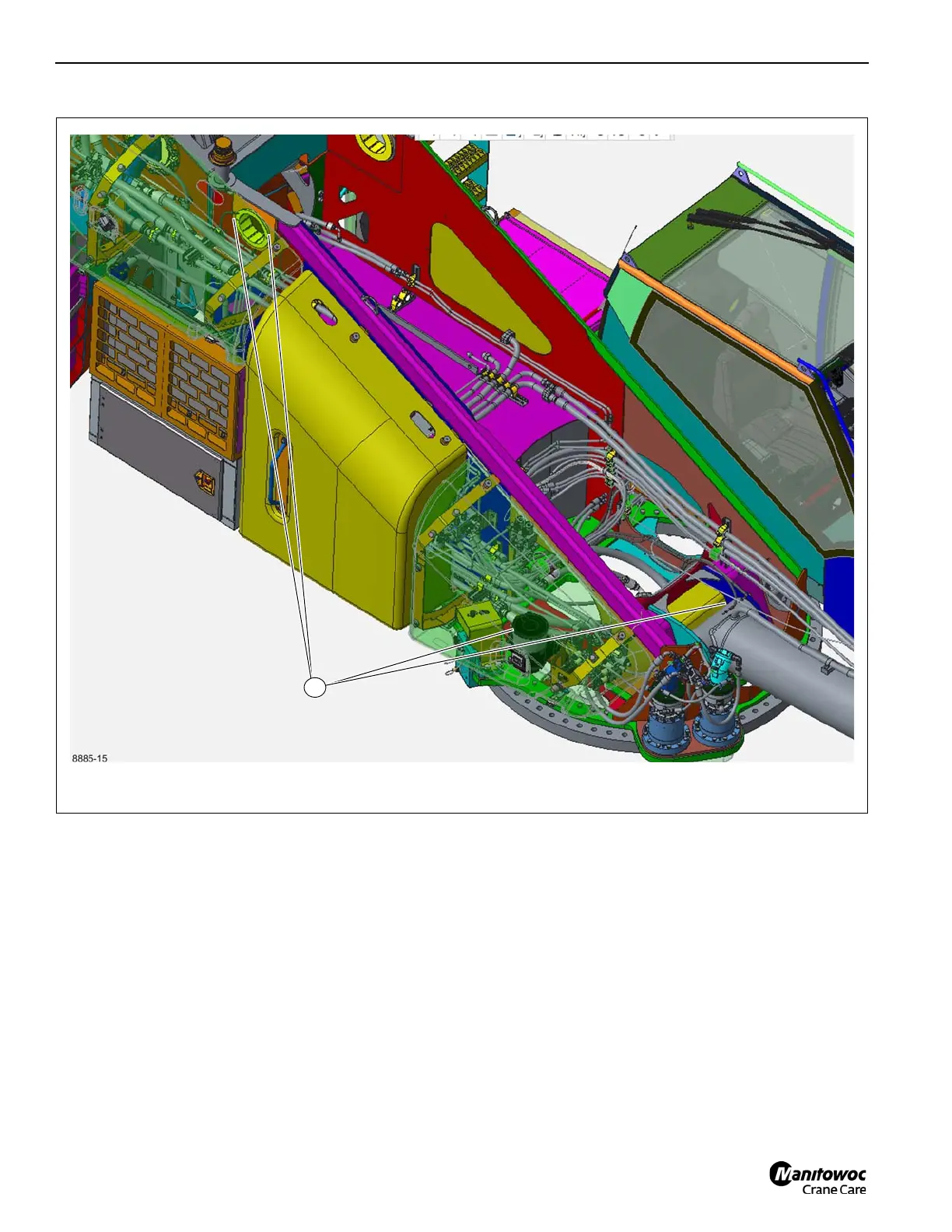

Greaseless Boom

The operator should make sure that each of the telescoping

boom sections are clean during operation. Any dirt that is on

the painted boom sections can get stuck in the wear pads,

and this will lead to scoring of the paint. Eventually, the

telescoping of a section with damaged paint will become

more difficult to complete as the paint damage becomes

more severe. Each of the telescoping boom sections should

be cleaned and wiped down with a non-solvent cleaning

agent at least once a month or as required.

The operator has the option to grease the boom if they so

choose. All of the grease fittings still exist in the boom.

However, from that point forward, the boom will always need

to be greased on a typical interval.

Loading...

Loading...