4-17

TMS9000-2 OPERATOR MANUAL OPERATING PROCEDURES

Published 02-21-2019, Control # 611-05

Traveling - General

Do not move the crane until the superstructure has been

secured as outlined below.

• Ensure the axles and/or suspension are not overloaded.

Refer to Axle Weight Distribution Table, page 4-23.

• Ensure all boom sections are fully retracted or set to

whatever extension is necessary for a balanced load on

the axles.

• Ensure the boom is fully lowered into the boom rest.

• If equipped, engage the optional 360° swing lock, except

for trailing boom mode.

• Ensure the swingaway, if so equipped, is properly

stowed and secured.

• Remove the hook block or headache ball from the hoist

cable(s) and stow securely before traveling or ensure

headache ball is properly secured to the tie down

provided for that purpose.

• Ensure the outrigger jacks and outrigger beams are fully

retracted and the floats are removed. Install outrigger

beams locking stirrups for retracted position.

• Ensure the jack floats are properly stowed in their

holding racks.

• Ensure the center front jack is fully retracted.

• Ensure the cover doors on the outrigger control panels,

battery box, and sling box are closed.

• Close and/or install all superstructure cab windows and

door.

Jobsite Travel Configurations

When traveling on jobsites with moderate slope the crane

shall be configured as shown in Table 1.

NOTE: The axle loadings are not evenly distributed for all

configurations. These unbalanced axle load

configurations should only be used occasionally

and are not intended for extended travel distances.

• Crane Operator must ensure proper tire inflation and

condition.

• For all the conditions, it is mandatory that the user verify

that the slewing system is set for crane operation and

not for trailing boom or boom dolly operation.

• Swing park brakes must be engaged and the swing

brake hydraulic bypass valve must be closed.

• If the crane is equipped with an optional 360 swing lock it

is recommended that this be engaged.

• Main Boom shall be fully retracted.

• When traveling with the boom over the front it is

recommended to keep the boom in the boom rest.

• When required, the 3-sheave hook block or headache

ball should be hanging 3 ft. below the sheaves and

secured to prevent swinging. No loads shall be lifted.

• When traveling with the boom over the rear it is

recommended that the boom elevation angle shall be

between 0 degree and 10 degrees maximum.

• The travel surface should be firm with no holes or bumps

exceeding a 4-inch variation over 3 ft. of travel (100 mm

over 1 m).

• Maximum travel speed is restricted to 2.5 MPH (4 km/h).

• Take care that turning maneuvers are performed using

the largest turning circle possible. Do not make any

sudden movements.

• Travel with 26.2 ft. (8 m) lattice insert erected is not

permitted.

CAUTION

Check cold tire pressure daily. Refer to tire inflation decal

on crane.

Job site travel with deflated suspension must be limited to

8 km/h (5 mph). Attempting to travel at higher speeds

may cause drive train component failure.

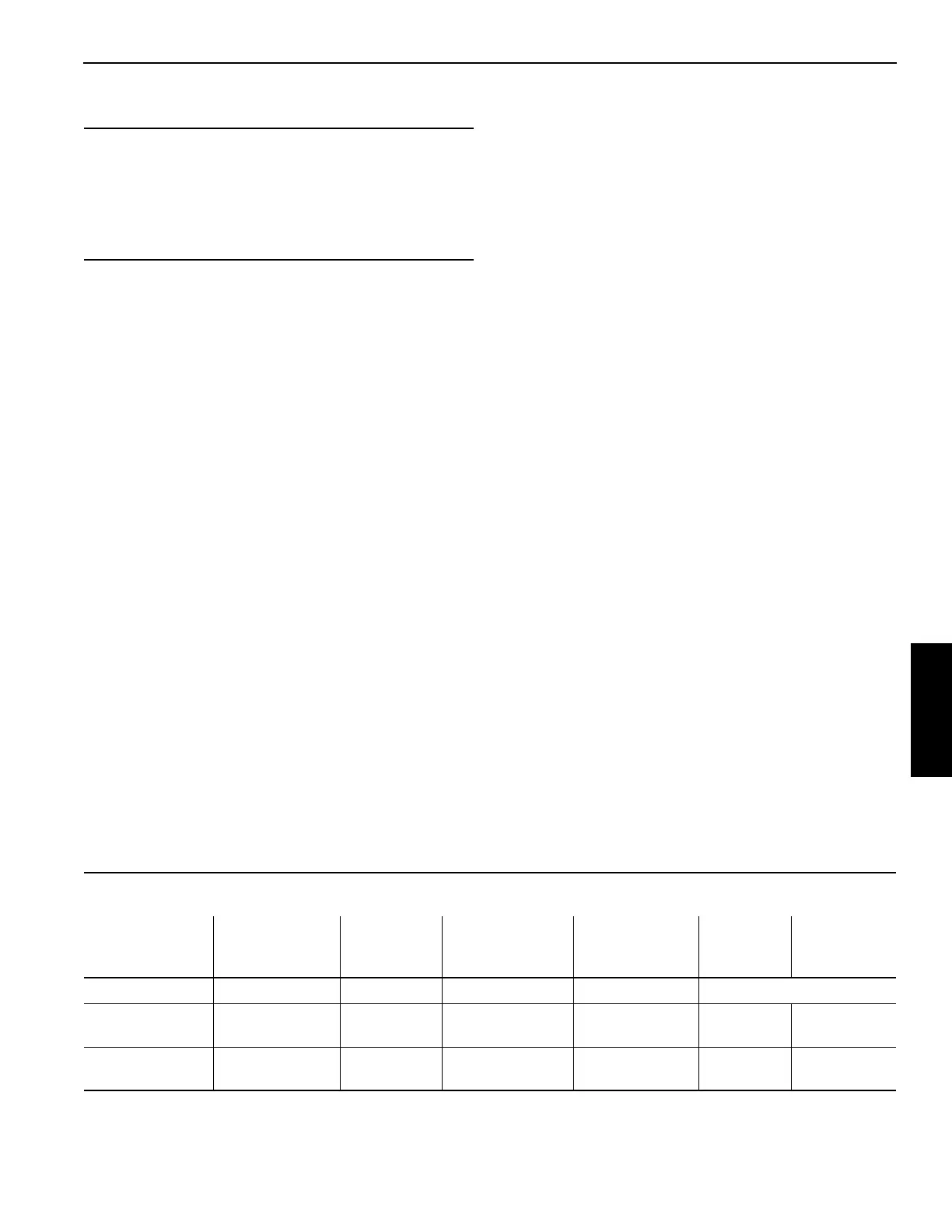

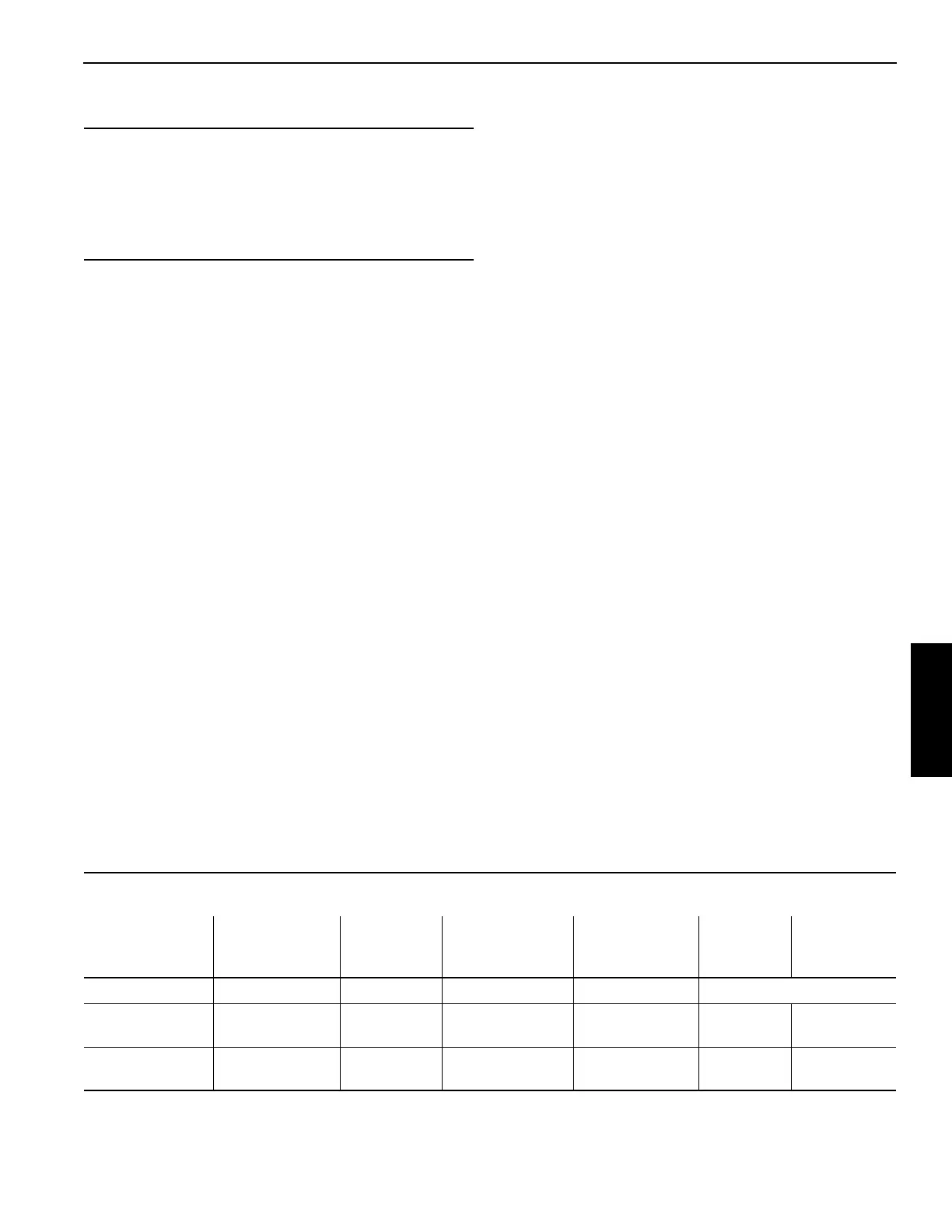

Table 1

Driving Rigged Crane with Boom at 0° Angle – 3-Sheave Hook Block Reeved Stowed Boom Extension or with

Boom Extension Removed

Counterweight

(LBS.)

Superstructure

Position

Main Boom

Angle (°)

Maximum Side

Slope (%)

Maximum Side

Slope (°)

Front Axle

Loads

(LBS.)

Rear Axle

Loads

(LBS.)

< 16,000 Over Front 0 10.0 5.8 See Weight Sheets

16,000 Over Front 0 10.0 5.8

20,050

31,300

18,000* Over Front 0 10.0 5.8

19,600

32,700

Loading...

Loading...