GROVE 6-63

TMS9000-2 OPERATOR MANUAL SET-UP AND INSTALLATION

Published 02-21-2019, Control # 611-05

Mechanical Luffing Boom Extension

(Adjustable Boom Extension)

Extension Angle Adjusting Mechanism

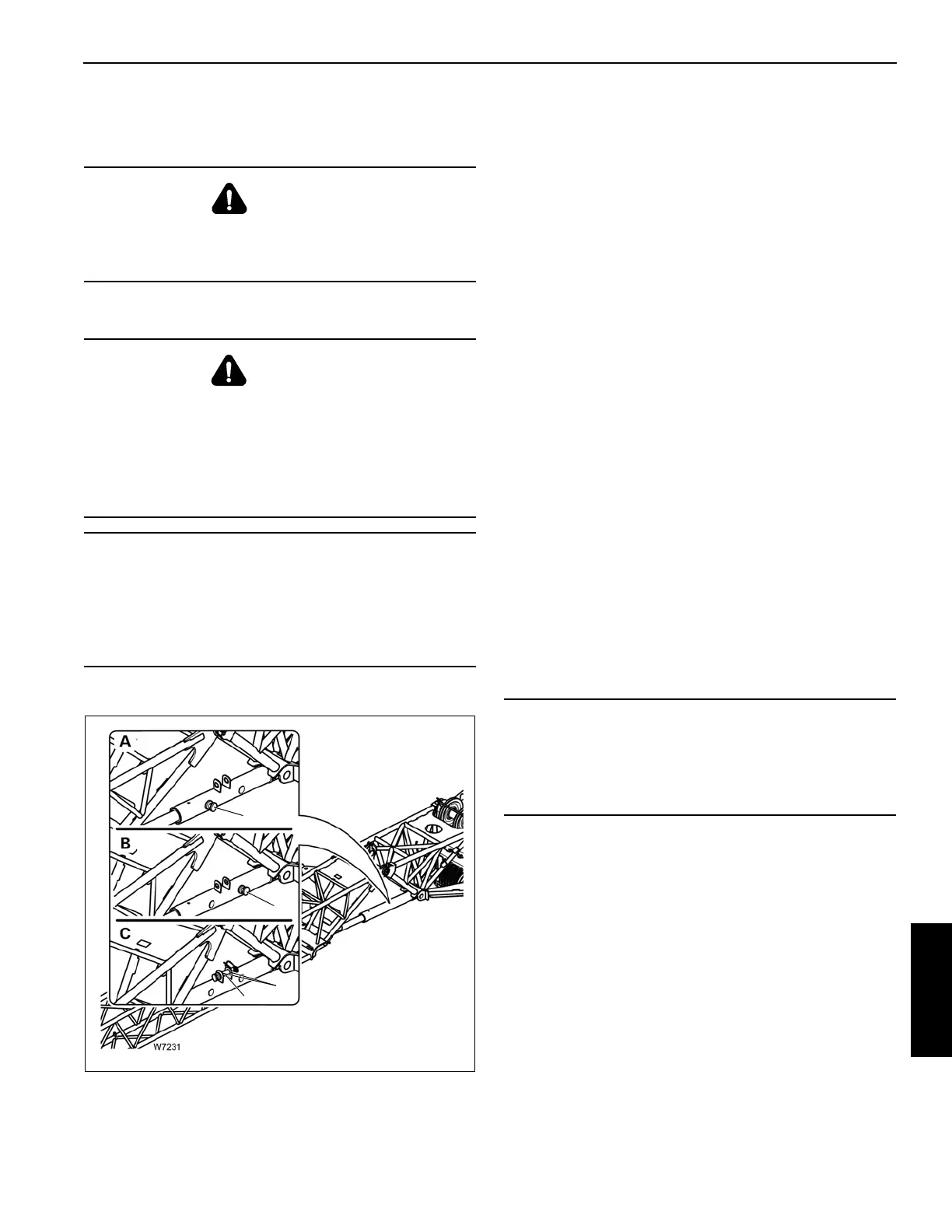

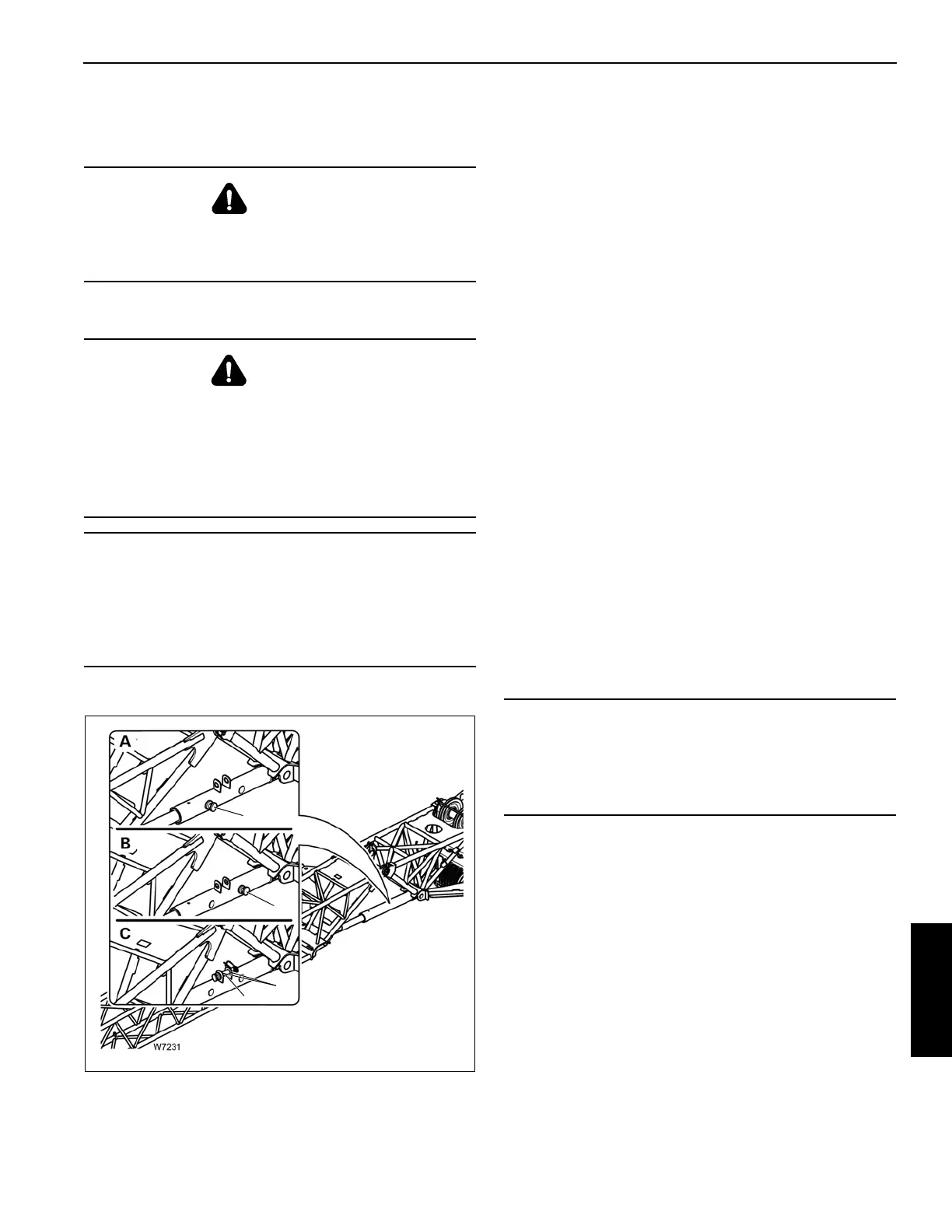

Refer to Figure 6-124.

The boom extension angle is determined by the position of

the adjusting pin. There are three positions:

•0° angle: (A) – For a 0° angle, the pin (1) is installed in

the front location and is secured with the retaining clip.

• 20° angle: (B) – For a 20° angle, the pin (1) is installed in

the rear location and is secured with the retaining clip.

• 45° angle: (C) – For a 45° angle, the pin (1) is removed

and stored in the holder (2) and secured with the

retaining clip.

Setting the Offset Angle with an Auxiliary Crane

NOTE: The information in this section only applies to the

mechanical luffing boom extension.

1. Lift the extension with the auxiliary crane until the pin (1)

(Figure 6-124) is relieved of load.

2. Lift or lower the extension with the auxiliary crane until

the adjusting pin can be installed into the position for the

required angle, refer to Extension Angle Adjusting

Mechanism, page 6-63.

3. Lower the extension with the auxiliary crane and remove

the lifting gear.

If the lattice extension now touches the ground at the

current angle, the angle will set itself when the main

boom is raised.

Setting the Offset Angle without an Auxiliary Crane

If an auxiliary crane is not available, the extension head must

rest on the ground before the angle is changed.

Entering the RCL Code

Enter the RCL rigging code for the boom extension offset

angle in accordance with the current rigging mode of the

crane, refer to the Load Chart, Chapter Remarks.

When adjusting the angle without an auxiliary crane, you

must enter an RCL rigging code. The RCL rigging code

depends on:

• the rigged outrigger span

• the rigged counterweight

• the working position.

The superstructure must be in a working position permitted

by the Load Chart for the RCL rigging code that was entered.

DANGER

Crushing Hazard!

During installation and removal, always use the proper

equipment with sufficient load bearing capacities.

WARNING

Crushing Hazard!

Uncontrolled movement of the boom extension can result

in death or serious injury. The Boom extension must be

supported before removing the adjusting pins.

Support the extension with an assist crane or set the tip of

the extension on the ground before adjusting the angle.

CAUTION

Machine Damage!

The deflection sheave must be stowed before adjusting

the offset angle of the extension. Failure to stow the

deflection sheave may result in damage to the extension

or sheave.

W7231

FIGURE 6-124

1

2

1

1

- 45°

- 0°

- 20°

CAUTION

Rope Damage!

The hoist cable can be damaged if it is reeved while the

extension nose is on the ground. Unreeve the hoist cable

from the extension nose before adjusting the offset angle.

Loading...

Loading...