4-11

TMS9000-2 OPERATOR MANUAL OPERATING PROCEDURES

Published 02-21-2019, Control # 611-05

Set the air distribution and ventilation nozzles.

Operation

Adjust the temperature and air flow as preferred by the

operator.

If the truck crane has been exposed to strong sunlight for a

long period of time, for example, the air conditioning system

should initially be operated at the highest blower level with

the engine running.

The door or at least the windows should be left open for a

short while to air thoroughly. The cooling-down procedure

can be accelerated by increasing the engine speed.

If the air-conditioning system is operated continuously, close

the windows and the door to ensure sufficient cooling.

Set the fan to a lower level once the inside temperature has

reached the desired temperature.

Drying the air

You can dry the air in the superstructure Cab.

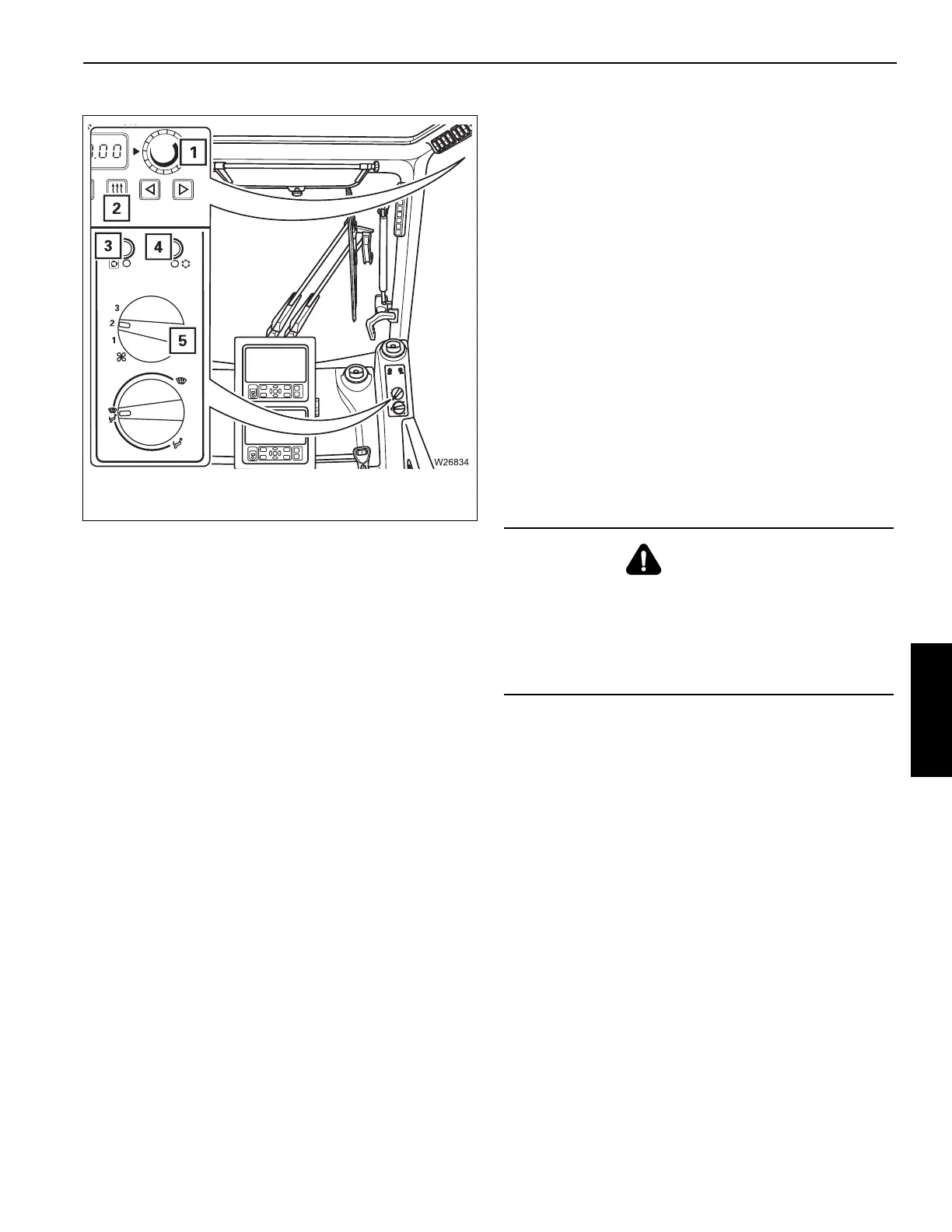

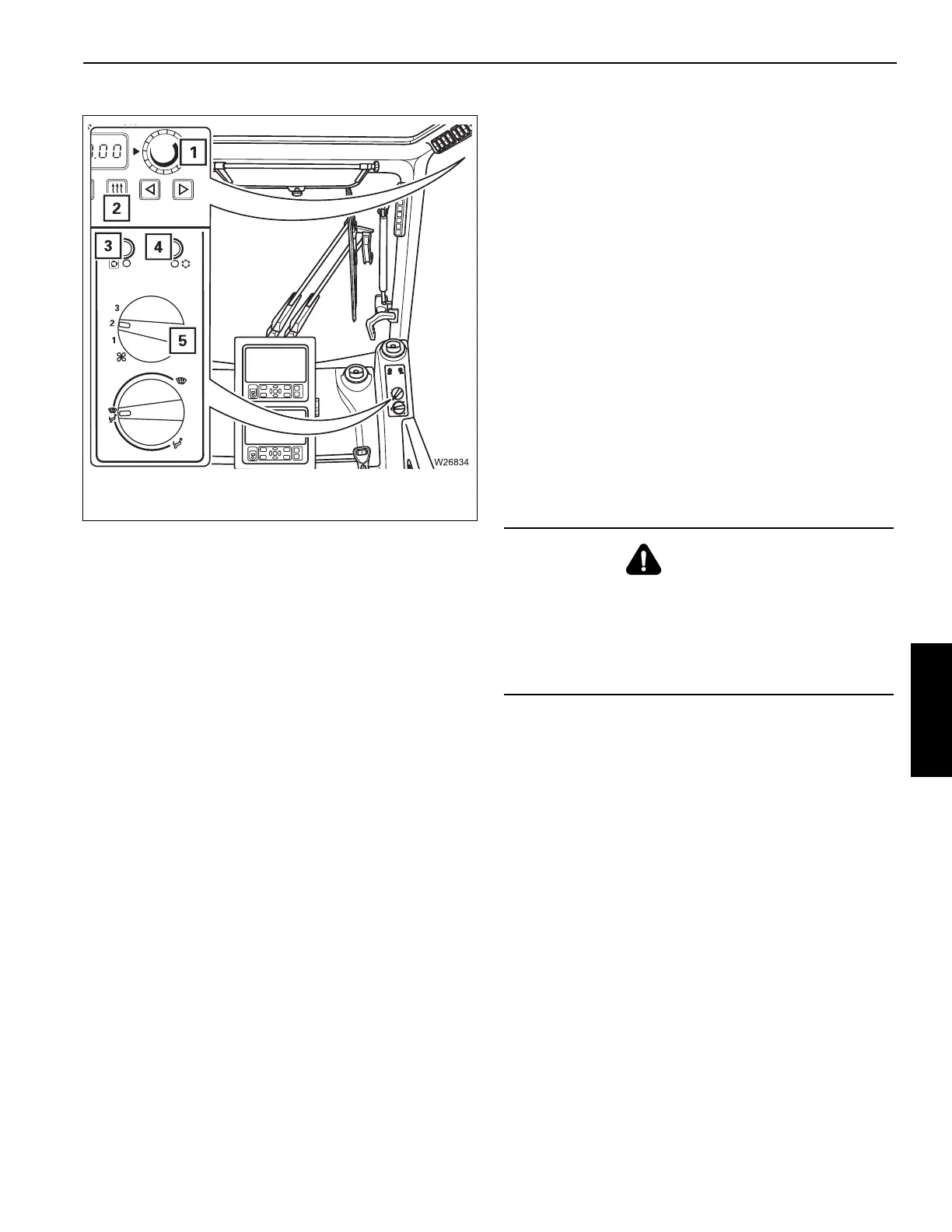

Switch the air conditioning on – press button (4, Figure 4-13)

– the button will illuminate.

At the heater control panel:

• Press button (2) once, heating on,

• Switch (1) as far as it will go to warm.

• Turn the switch (5) to the required level.

• Button (3) on the Recirculated air symbol – lamp on.

When drying, the air conditioning system and the heating

system work against each other. After drying, switch off the

device that you do not require.

Switching off

Switch the air-conditioning system off:

Press the button (4, Figure 4-13) – button lamp goes out,

If you do not wish air to be circulated, turn the switch (5) to

the off position.

ANTI-LOCK BRAKE SYSTEM (ABS)

The crane has a standard brake system, equipped with an

electronic speed monitoring and control system, Anti-Lock

Brake System (ABS). ABS monitors wheel speed

continuously but is not involved in controlling the wheel

speed unless there is a reduction in traction. In normal

braking applications, the standard air brake system is in

effect.

NOTE: For more information on the ABS/ATC systems

refer to the Service Manual.

There is a sensor installed in each wheel. Due to system

constraints, only axles 2, 3 and 4 are monitored. The first

steer axle has sensors installed but they are not connected.

The sensors transmit information to the EC-60™ Premium

electronic control unit (ECU). The ECU interprets the signals

and calculates wheel speed, wheel retardation and a crane

reference speed. If the calculations indicate a wheel lock-up

situation, a signal is sent from the ECU to the appropriate

ABS modulator valve to reduce braking pressure. During

emergency braking, the modulator valve alternately reduces,

increases or maintains air pressure in the brake chamber to

prevent wheel lock-up.

During emergency or reduced-traction stops, fully depress

the foot brake pedal until the crane comes to a safe stop. DO

NOT PUMP the brake pedal. With the brake pedal fully

depressed, the ABS will control all wheels to provide steering

control and a reduced braking distance.

Although the ABS improves crane control during emergency

braking situations, the operator still has the responsibility to

change driving styles depending on the existing traffic, road

and/or weather conditions. For example, the ABS cannot

WARNING

For proper ABS operation, do not change tire sizes. The

size of the tires installed during production are

programmed into the electronic control unit. Installing

different size tires could result in a reduced brake force,

leading to longer stopping distances, which may cause

serious injury or death.

Loading...

Loading...