– 4.9 –

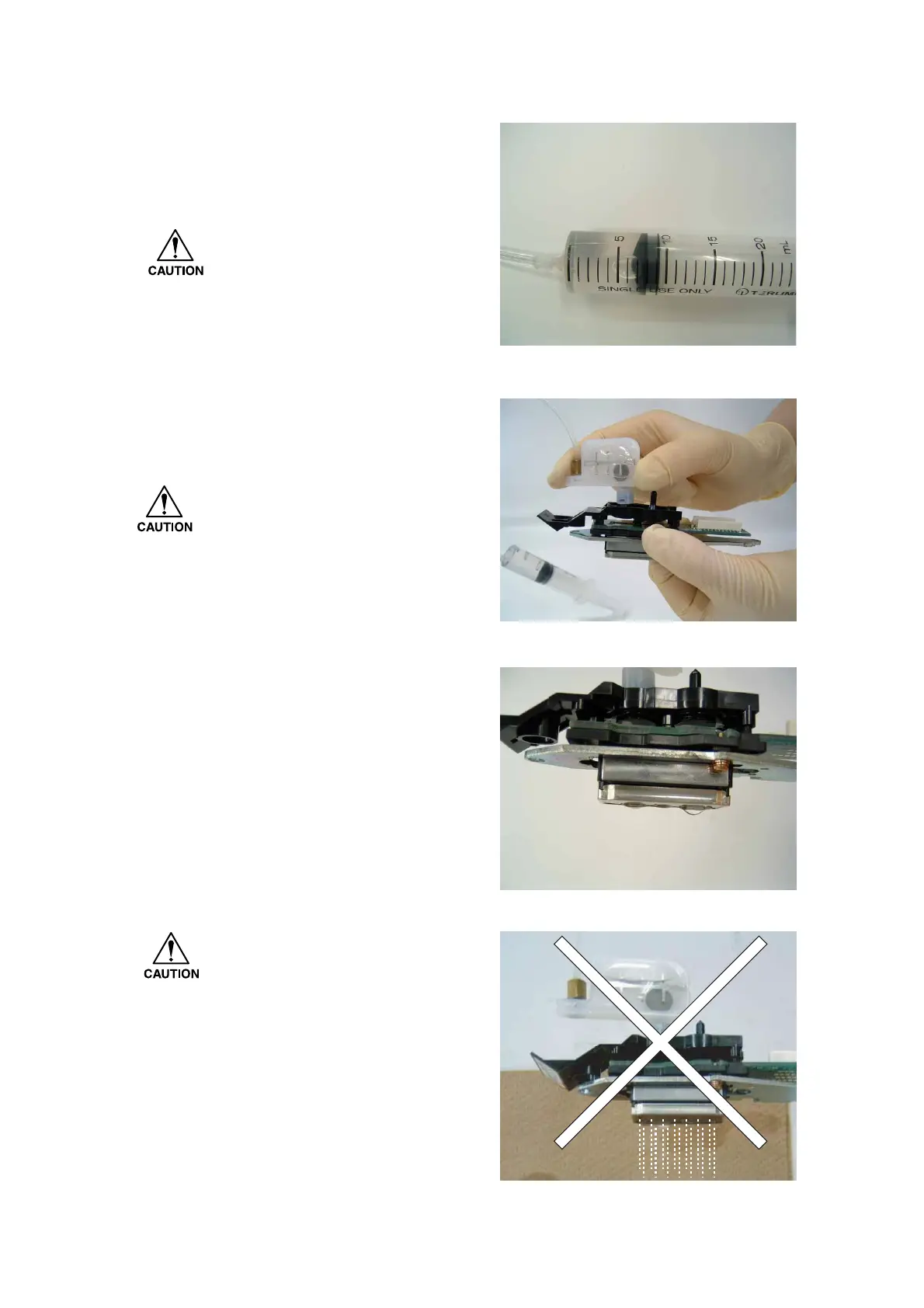

2) Pour the cleaning liquid for exchanging

(MS cleaning liquid ) for both nozzles

(6-8cc) into a syringe.

• Rubber in syringe is not solvent

resistance, and must be replaced

regularly.

Deterioration of the rubber seal

may cause the fluid to leak on to

the head, causing damage to the

plotter components.

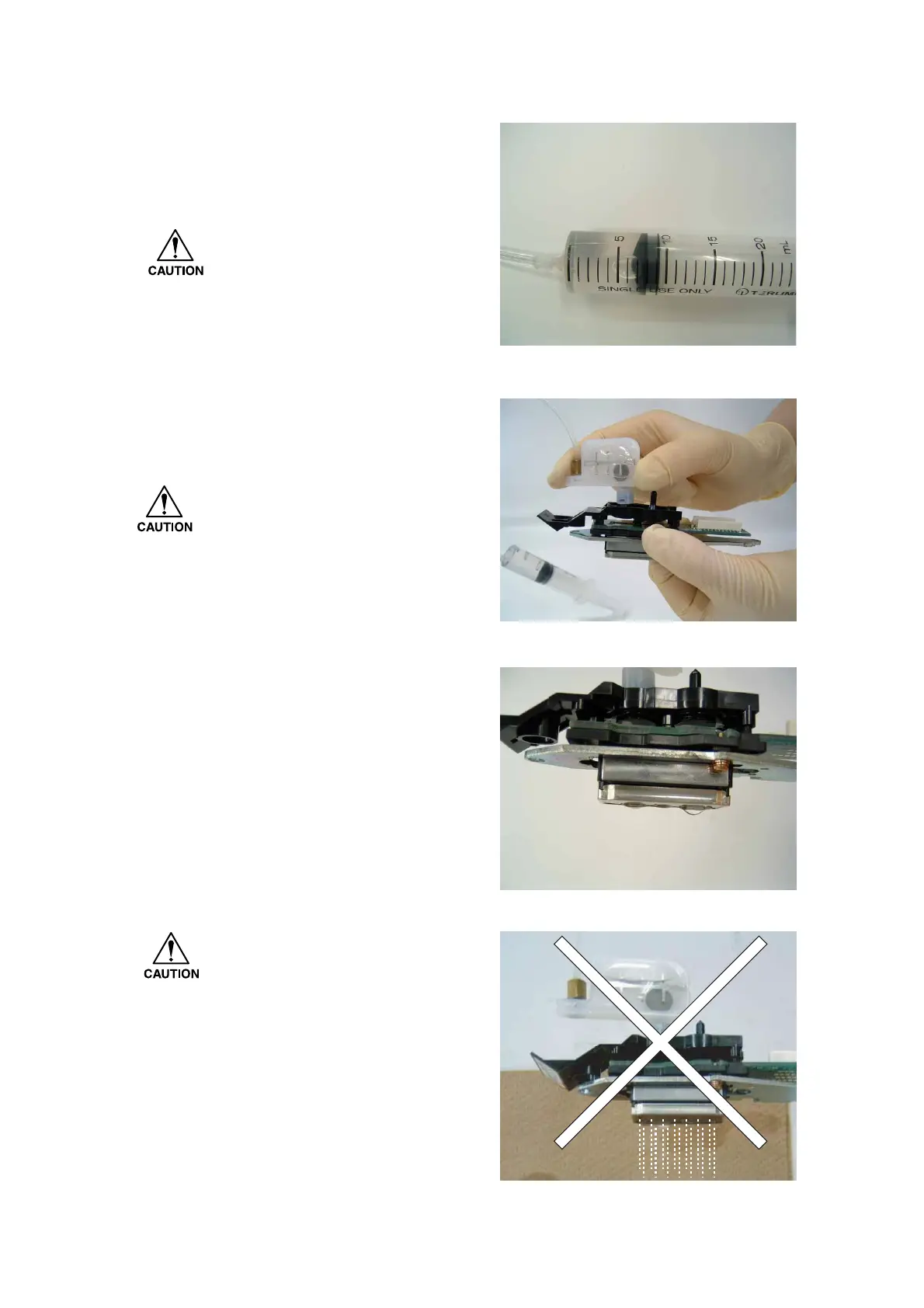

3) Insert it firmly into a slot of a damper.

• Be careful not to leek the cleaning

liquid to head from a damper.

4) Pour 3-4cc cleaning liquid for one nozzle

taking approx. 30 seconds.(Do not push

a syringe strongly, or the damper may

be damaged.)

• Do not push and clean up the

syringe strongly, or the head may

be damaged.

Loading...

Loading...