– 4.27 –

[The case that needs adjustment]

• In the case where the Y-motor total assy is removed.

[Tools to be used]

• Phillips screwdriver (No.2 for M3 to M5)

• Tension gauge (Max. 300 gf or more)

• Scale (L=150)

[Adjusting procedure]

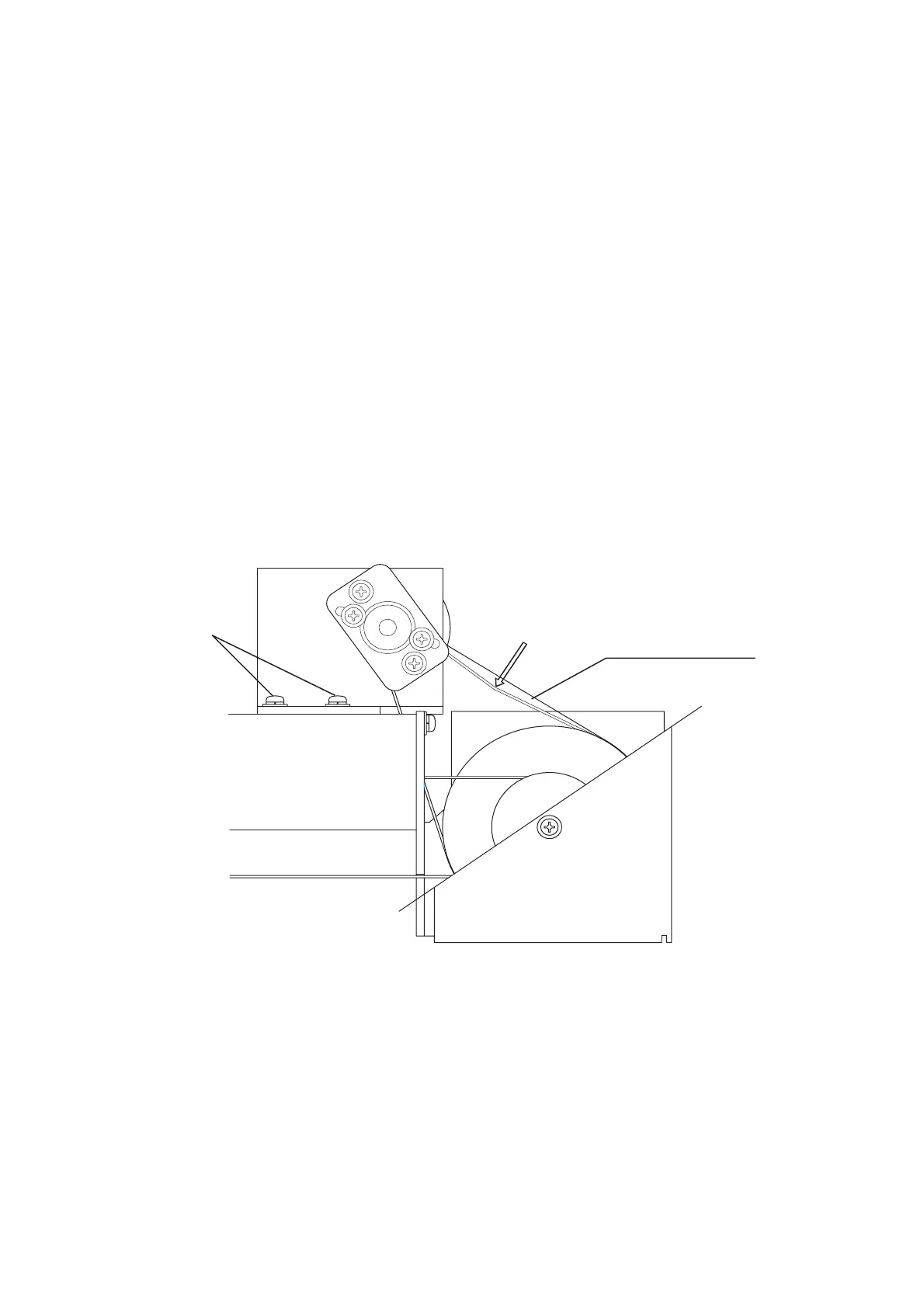

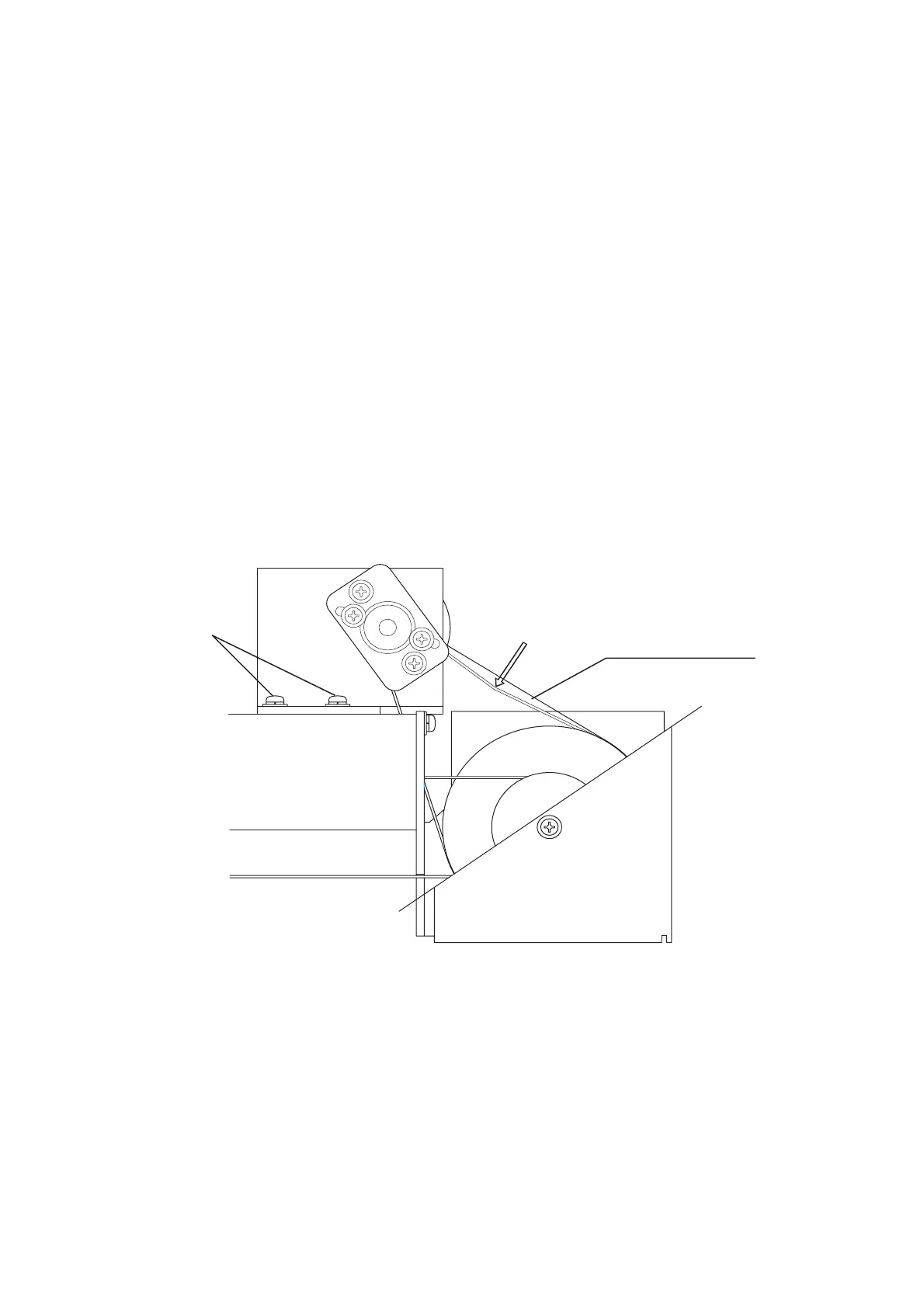

1) Loosen the screw in the Y-motor total assy.

2) Adjust the Y motor total assy position so that when the middle of the timing belt is pressed

down with 250 gf, it bends between 1.6 mm and 2.0 mm, then fix in the place.

Y motor total assy

mounting screw

250 gf

Bending amount 1.6 mm to 2.0 mm

Loading...

Loading...