NORDAC FLEX (SK 200E ... SK 235E) – Users Manual for Frequency Inverters

266 BU 0200 en-3118

Pos: 73 7 /Anlei tung en/El ektr onik/FU und Star ter/8 . Zus atzinfor mati one n/Ener giee ffizie nz_01 (Ü bers chrift) [SK 1 x0E, SK 2 xxE, SK 5 xxE, SK 2x xE-FDS ] @ 19\mod_1511882003738_388.docx @ 2374149 @ 2 @ 1

8.7 Energy Efficiency

Pos: 73 8 /Anlei tung en/El ektr onik/FU und Star ter/1 . Allg emei nes/Sic herh eits- und Ins tall ations hinwei se un d Warn- Gefahrenhinweise/neu/Warn- und Gefahrenhinweise/WARNUNG - Unerwartete Bewegung durch Überlast @ 19\mod_1511882404385_388.docx @ 2374221 @ @ 1

WARNING

Unexpected movement due to overload

In case of overload of the drive there is a risk that the motor will "break down" (= sudden loss of torque). An

overload may be caused e.g. by underdimensioning of the drive unit or by the occurrence of sudden peak loads.

Sudden peak loads may be of a mechanical origin (e.g. blockage) or may be due to extremely steep acceleration

ramps (Parameter P102, P103, P426).

Depending on the type of application, "breakdown" of the motor may cause unexpected movement (e.g. dropping

of loads by lifting gear).

To prevent any risk, the following must be observed:

• For lifting gear applications or applications with frequent, large load changes, the parameter (P219) must

remain in the factory (100 %).

• Do not underdimension the drive unit, provide adequate overload reserves.

• If necessary, provide fall protection (e.g. for lifting gear) or equivalent protective measures.

Pos: 73 9 /Anlei tung en/El ektr onik/FU und Star ter/8 . Zus atzinfor mati one n/Ener giee ffizie nz_02 [S K 1x0E, SK 2xx E, SK 5xxE , SK 2xx E-FDS] @ 1 9\mod_1511882035669_388.docx @ 2374185 @ @ 1

NORD frequency inverters have a low power consumption and are therefore highly efficient. In

addition, with the aid of "Automatic flux optimisation" (Parameter (P219)) the inverter provides a

possibility for increasing the overall efficiency of the drive in certain applications (in particular

applications with partial load).

According to the torque required, the magnetisation current through the frequency inverter or the

motor torque is reduced to the level which is required for the momentary drive power. The resulting

considerable reduction in power consumption, as well as the optimisation of the cos φ factor of the

motor rating in the partial load range contributes to creating optimum conditions both with regard to

energy consumption and mains characteristics.

A parameterisation which is different from the factory setting (Factory setting = 100%) is only

permissible for applications which do not require rapid torque changes. (For details, see Parameter

(P219))

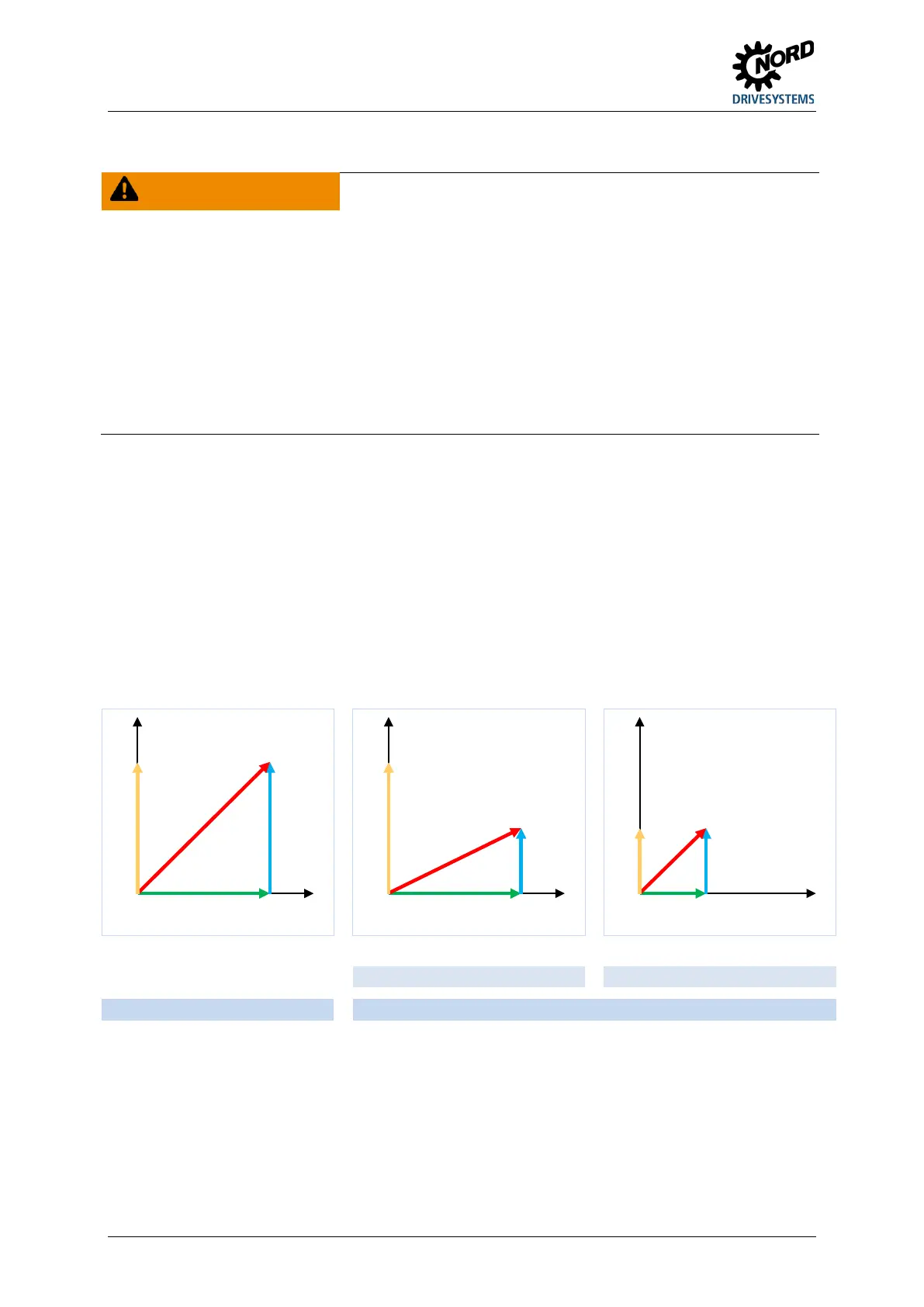

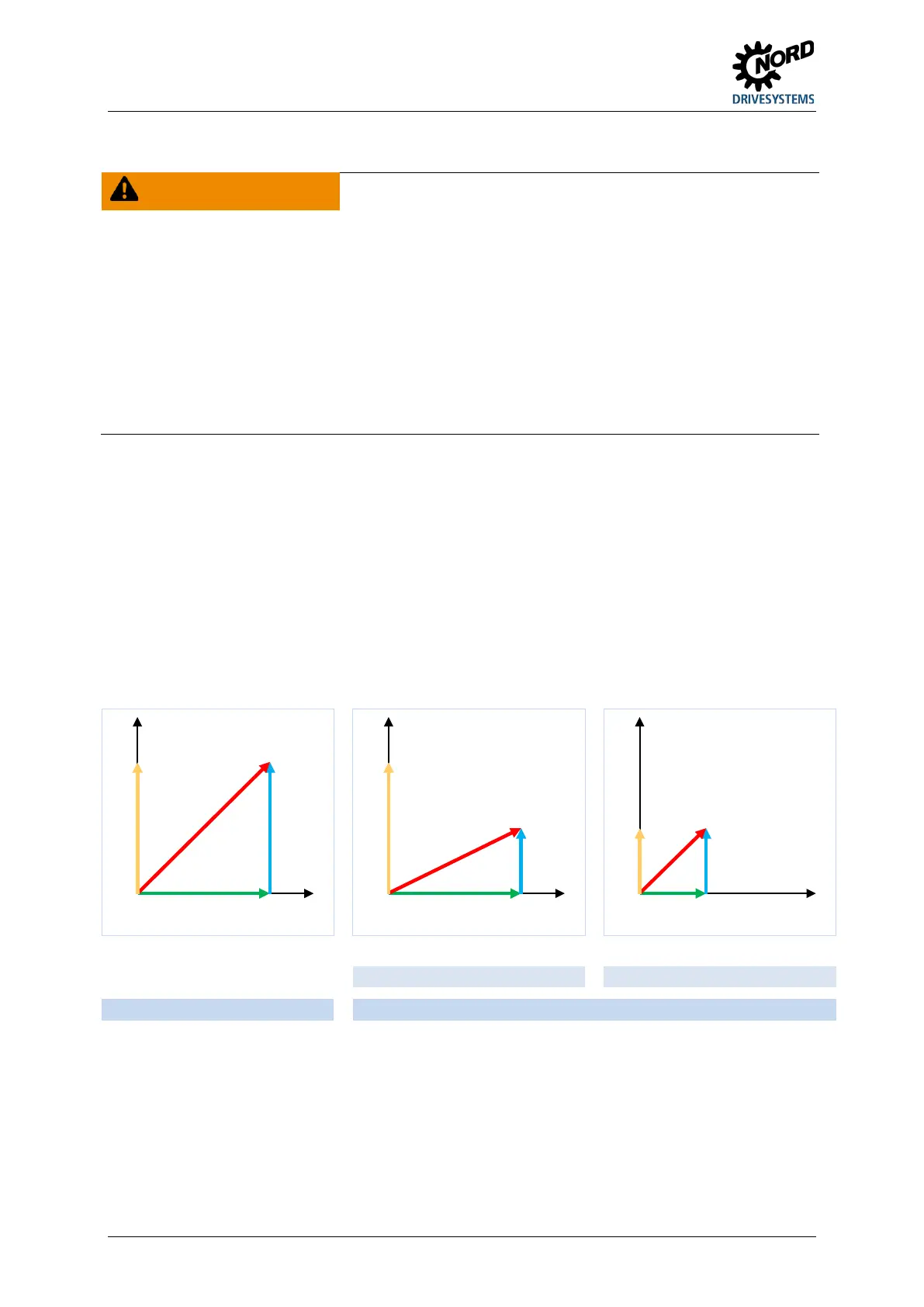

I

S

= Motor current vector (line current)

SD

Magnetisation current vector (magnetisation current)

SQ

Load current vector (load current)

Figure 37: Energy efficiency due to automatic flux optimisation

Pos: 74 0 /Allg emein/ Allg emeing ültig e Module/---------Seitenu mbruc h komp akt --------- @ 13\mod_1476369695906_0.docx @ 2265495 @ @ 1

I

SD

I

SQ

I

S

U

I

SD

I

SQ

I

S

U

I

SD

I

SQ

I

S

U

Loading...

Loading...