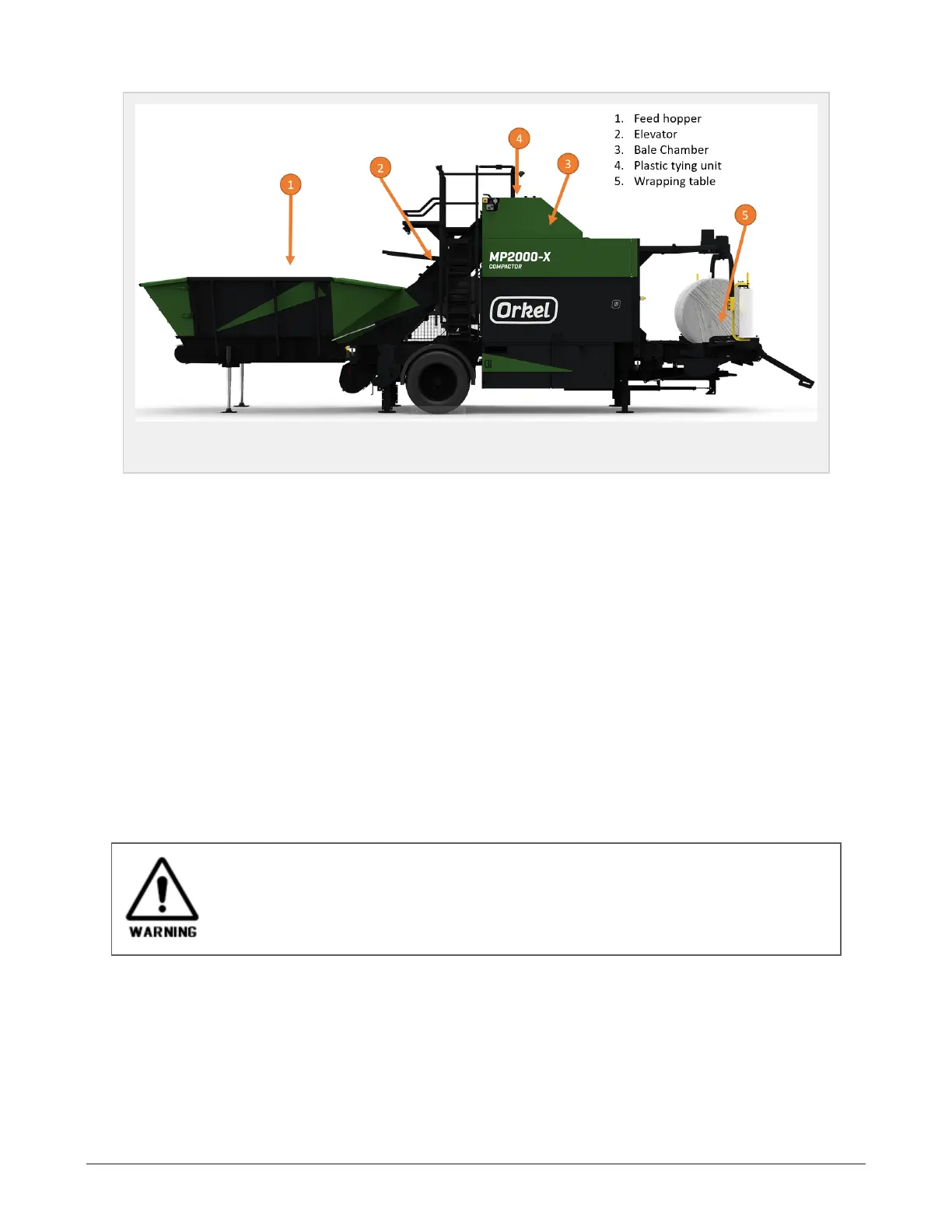

3.1 MAIN PARTS

Figure 3.1 :

The compactor main parts

3.1.1 Principle of operation

The material is loaded into the feed hopper using a wheel loader, or directly by a conveyor belt. The mater-

ial is then transported by the elevator into the chamber. The amount and speed is controlled by an ultra-

sonic sensor as well as settings in the display unit. All functions and settings may be adjusted depending

on the characteristics of the material being baled.

When the material has been shaped to a compact bale, several layers of net or film is laid on the bale by

the net/film system. The net/film ensures that the bale maintains its shape during the transport to the

wrapper. The chamber door is opened automatically and the bale is transported to the wrapper by the sub

conveyor. The chamber door closes and the baling immediately resumes. If there is any spillage, this will be

recycled back to the elevator by the sub conveyor.

The wrapping starts as soon as the bale is detected on the wrapping table. Parameters such as chamber

pressure and the number of layers of film may be set on the display unit. During normal operation, the

machine runs on the automatic sequence. The operator(s) main task is to ensure that there is a sufficient

amount of material in the hopper and that the finished bales are moved away from the bale drop zone. The

operator shall also check for leaks and listen for unusual sounds while performing tasks as refilling the

plastic magazine.

3.2 HYDRAULICS

The compactors hydraulic system operates with high pressure. Check all hoses and con-

nections for damage. Replace damaged parts immediately. When adjusting the machines

hydraulic valves, being within the wrappers area of movement is not allowed. Take cautions

when adjusting the valves, as the wrapper arms speed may change rapidly. Make yourself famil-

iar with all the functions of the machine.

The default setting of the machine is done during the test run at the factory. Before performing any

changes or testing on the machine, the hydraulic oil must have reached normal work temperature. This is

because certain functions are affected by the oils viscosity and may respond differently if the oil is cold.

For recommended oil types to be used, see section 8.6.1 "Hydraulics" . In the description of how to adjust

the machines hydraulic valves, the valves are referred to by valve numbers. See overview in section 11.2

"Valve overview".

3 SETTINGS AND HYDRAULIC ADJUSTMENTS 23

Loading...

Loading...