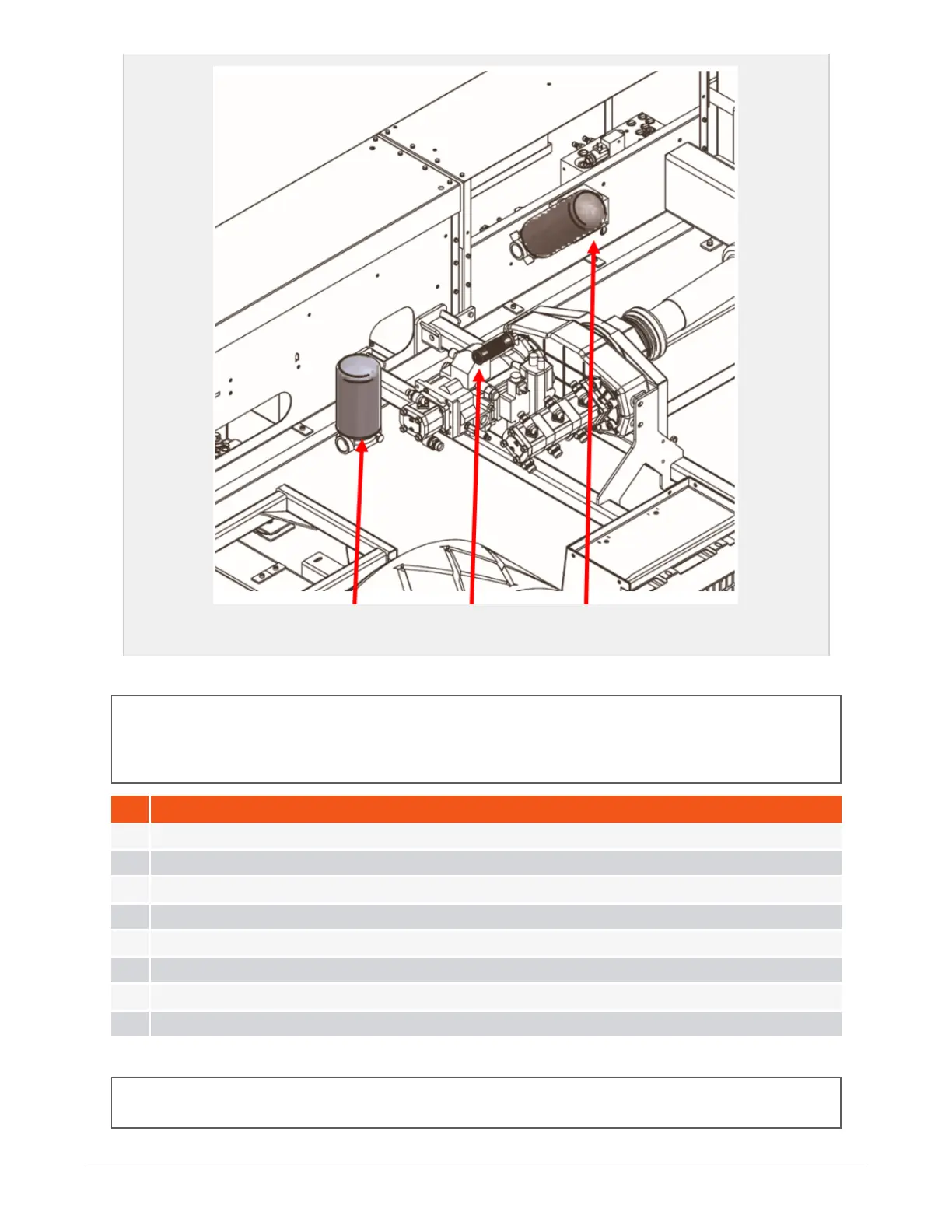

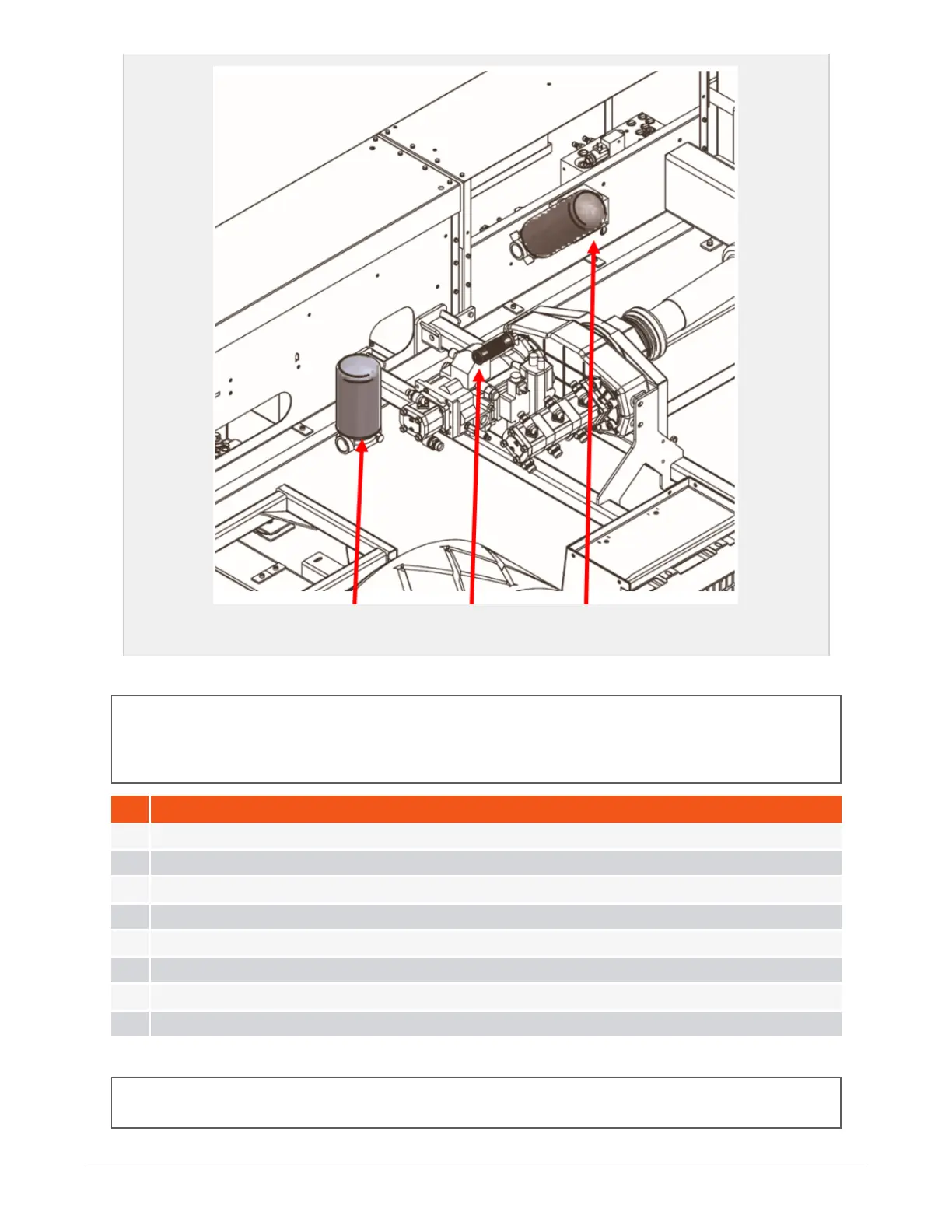

Figure 4.2 :

Filters

IMPORTANT:

Orkel recommends that the operator regularly performs visual controls of the compactor as well as act-

ive listening for abnormal noises. Perform adjustments as soon as there is a need. A problem that is not

immediately rectified may cause further problems, and in worst case lead to mechanical breakdown.

No Checkpoints during and after break-in period

1 Grease collar. Check that all bearings have grease collar.

2 Perform visual control of the compactor – before, during and after use.

3 Grease pump. Check pressure relief valve, no visible grease shall be present.

4 Elevator chain. Check tension after 1-3 hours of operation

5 Check and adjust elevator and sensor.

6 Replace filters after the first 50 hours of operation.

7 Change hydraulic oil after 50 hours of operation.

8 Listen for abnormal noises.

4.5 AUTOMATIC OPERATION

IMPORTANT: If the tank valves are closed when the PTO is started, there is a high risk of damaging the

hydraulic system. Before starting, please make sure that all tank valves are open. See section 11.2 "Valve

4 OPERATION 40

Loading...

Loading...