NOTE: The wrapping arms low speed needs to be set correctly in order to ensure the correct orientation to the

film cutters. The wrapping arm speed may increase when the oil is warm. Therefore, closely monitor the wrap-

ping arm slow speed and readjust if needed. The position of sensor S5 may also need to be readjusted.

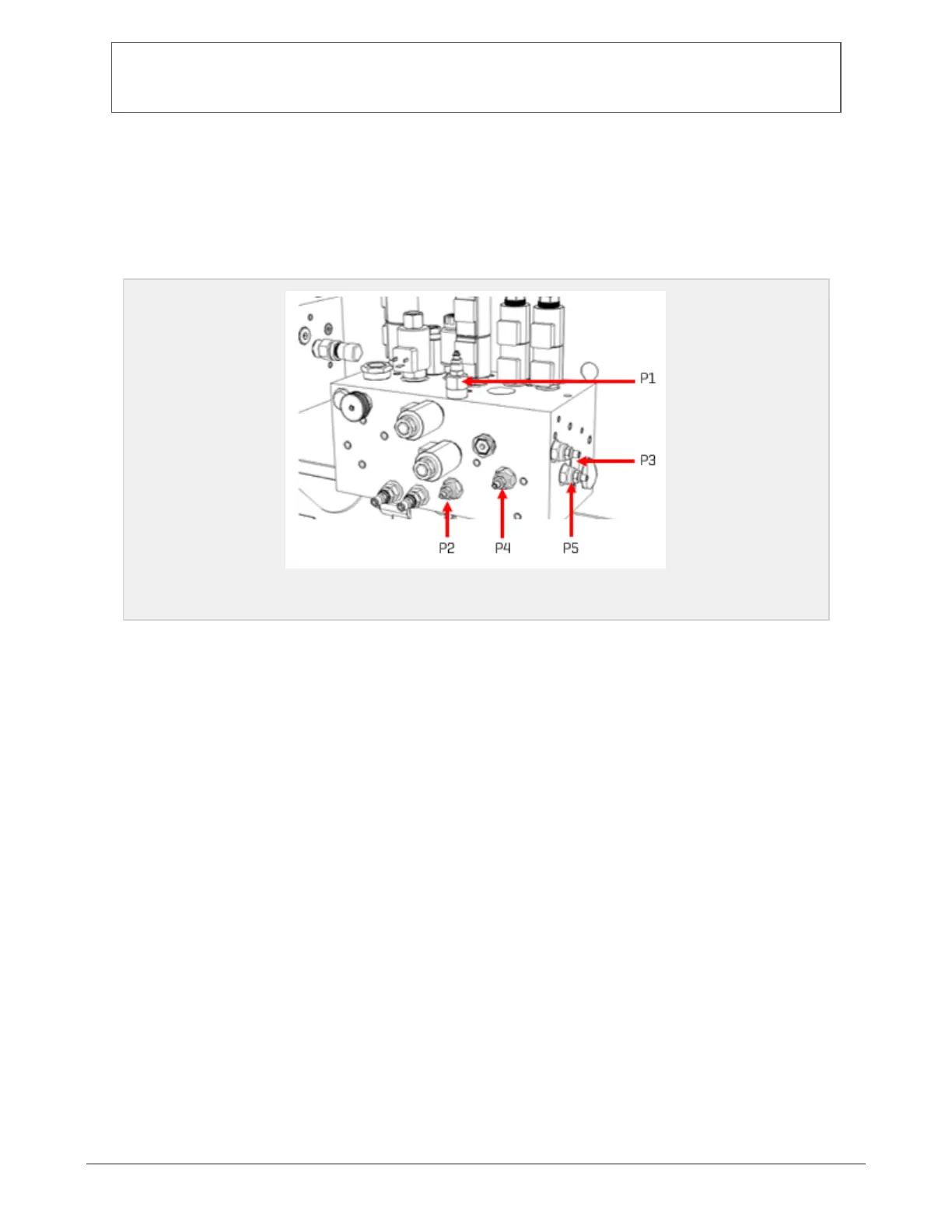

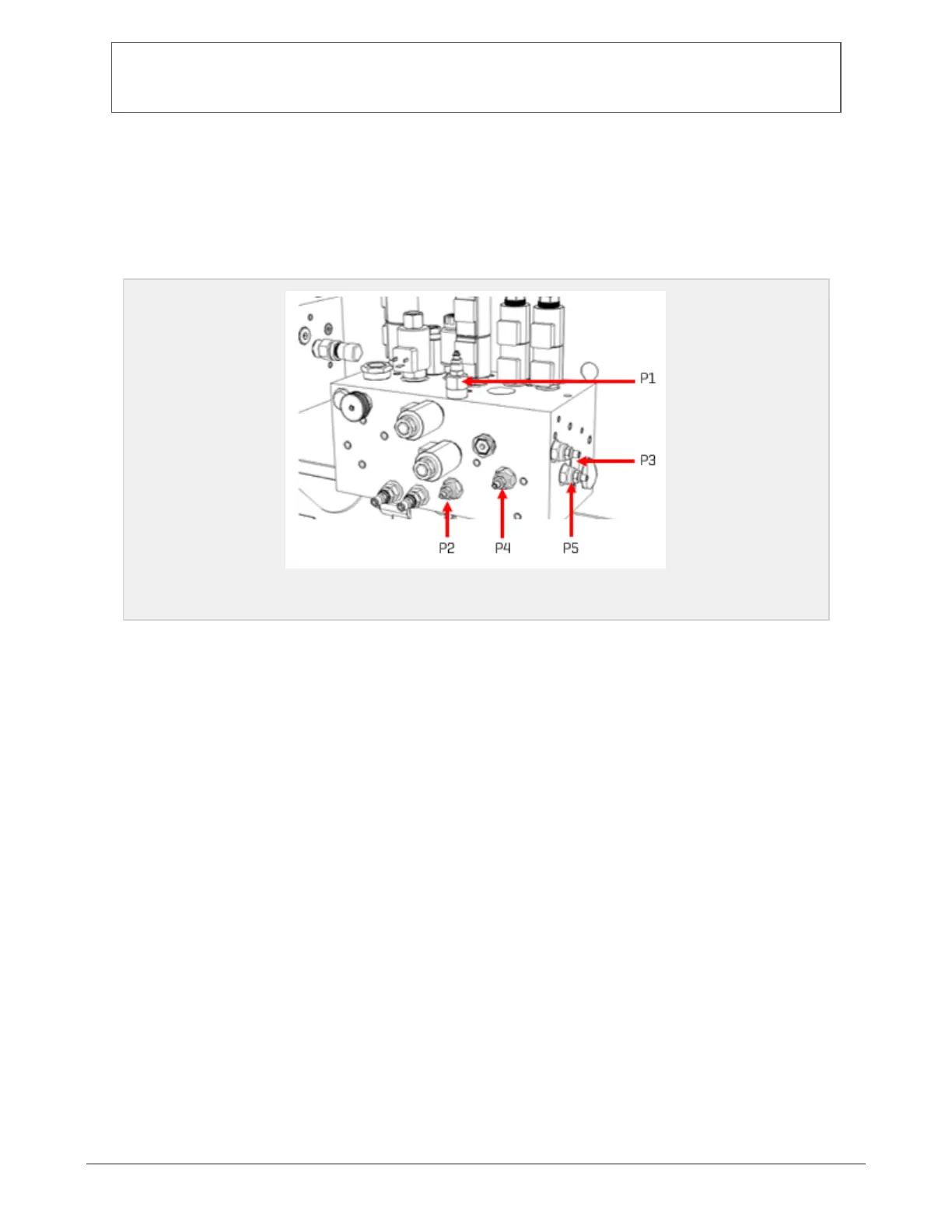

3.7.2 Film cutter settings

The opening and closing speed of the film cutters must be set correctly. If their speed is too high, the wrap-

ping film might be damaged instead of neatly cut when the wrapping arms stop. The film cutters speed,

left (valve P4) and right (valve P5), may be reduced by turning the valve clockwise. Both cutters should be

equally set. The cutters should move softly.

Default setting: Close the valve and then open 1/2 turn.

Figure 3.6 :

Film cutter valves

Setting the speed: Turning the valve clockwise decreases the speed. Turning the valve counterclockwise

increases the speed. Adjusting the height of the cutters is normally not necessary. The film should lay on

the middle of the cutter when cut.

Film cutter rollers: Film cutter, upper position: Both rollers must roll freely. Film cutter, lower position: The

outer roller should be kept locked. This is in order to hold the film so that it is cut, not ripped. Make sure

that the knife is centred between the two rollers. Straighten the knife, if necessary. See Figure 3.7

3 SETTINGS AND HYDRAULIC ADJUSTMENTS 29

Loading...

Loading...