TIMING CASE AND DRIVE ASSEMBLY 15

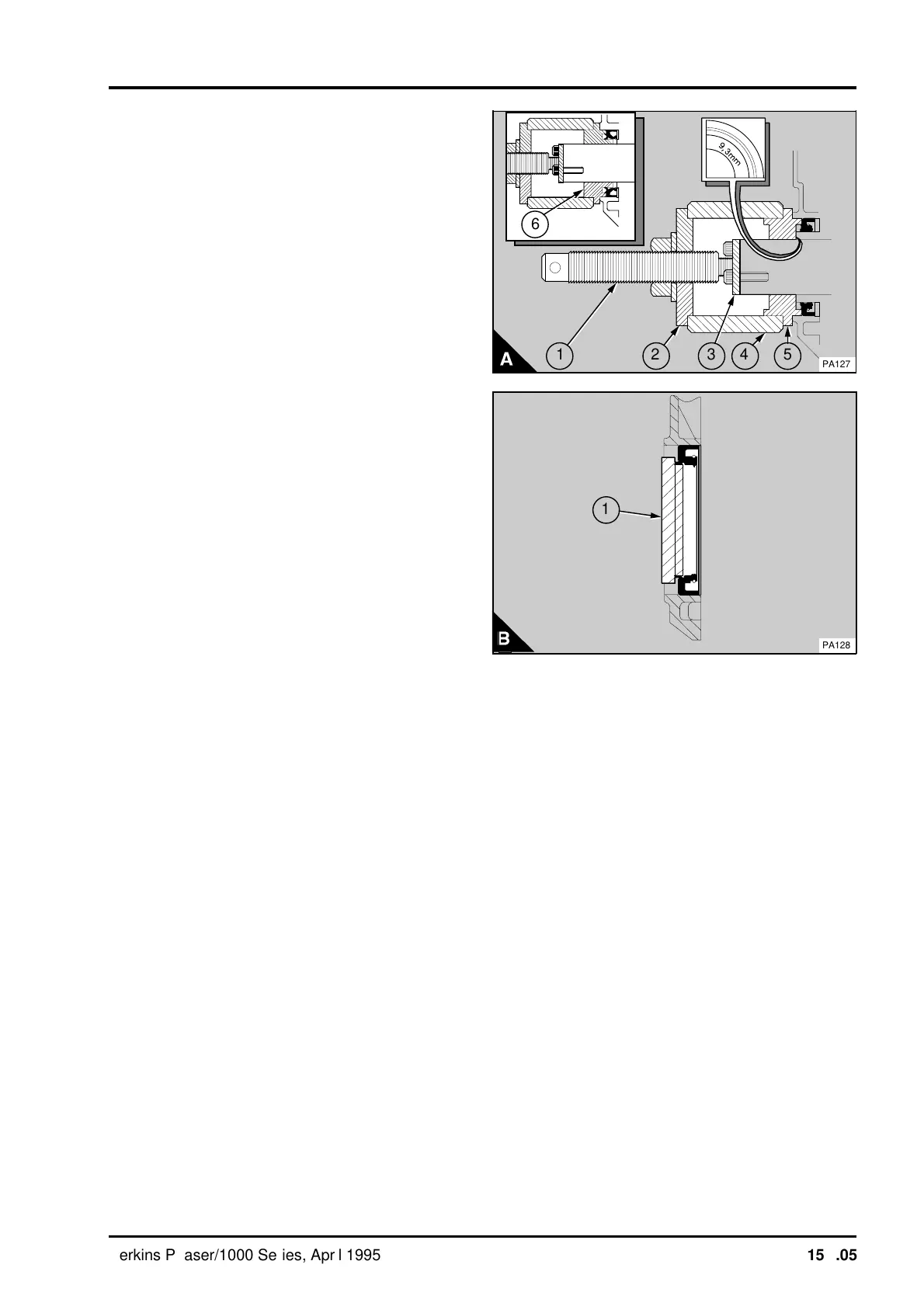

1 Clean the oil seal housing. Inspect the new seal

for damage. If a scratch can be seen across the lip

of the seal, do not fit the seal.

2 Lubricate the outer circumference of the oil seal

with clean engine lubricating oil and enter the seal

into the housing. Ensure that the spring loaded lip

of the oil seal is towards the inside of the timing

case cover and that the oil seal is square to the

bore of the seal housing. When a water immersion

seal is to be fitted, keep the plastic mandrel (B1) in

position until it is time to fit the adaptor PD.170-8.

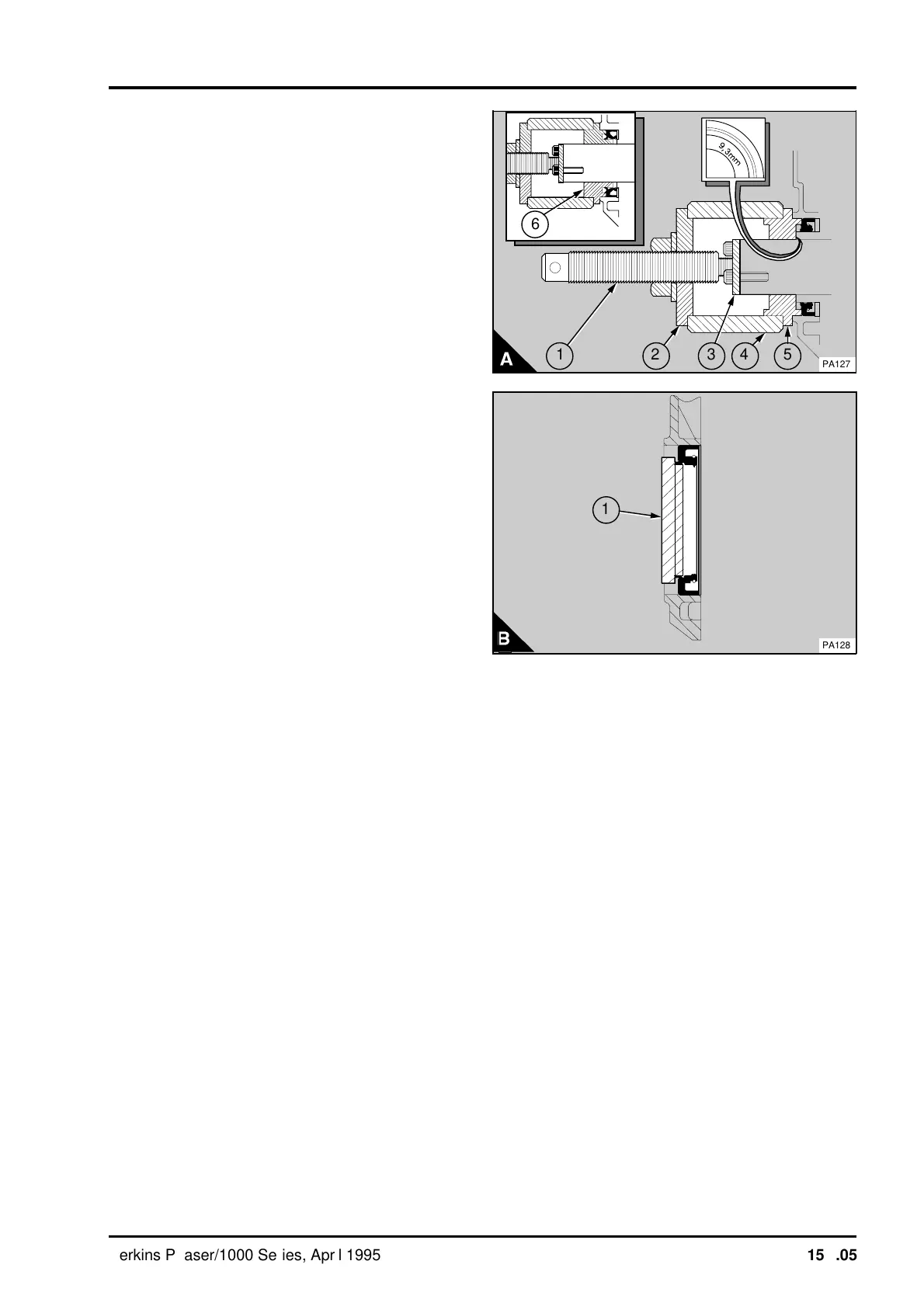

3 Assemble the oil seal replacer tool (A). Fit the

fastener plate, PD.170-3, (A3) to the front of the

crankshaft. For the standard seal, put the adaptor,

PD.170-4, (A5) on the nose of the crankshaft and

against the seal. Ensure that the adaptor has the

side stamped 9,3 mm towards the seal. When a

water immersion seal is to be fitted, remove the

plastic mandrel from the seal and fit the adaptor

PD.170-8, (A6). When the adaptor is fitted, ensure

that the front lip of the seal is fully onto the taper of

the adaptor.

Note : The other side of adaptor PD.170-8 can also

be used to fit the standard seal.

Assemble the pressure plate, PD.170-1, (A2)

together with the sleeve, PD.170-2, (A4) onto the

threaded bar, PD.170, (A1). Put the tool assembly

in position on the adaptor, PD.170-4 or PD.170-8,

and tighten the threaded bar onto the stud of

PD.170-3 (A3).

Fit a rod through the hole in the end of the threaded

bar to prevent movement of the bar when the nut is

tightened. Tighten the nut to push the seal into the

housing to the correct depth. If the standard seal is

to be pushed in to the service position, turn the nut

until the face of PD.170-4 is against the face of the

seal housing. If a water immersion seal is to be

fitted, the adaptor, PD.170-8, should also be

pushed fully onto the face of the seal housing.

4 Remove the replacer tool and lightly lubricate the

seal location area of the crankshaft pulley with

clean engine lubricating oil. Fit the crankshaft

pulley, operation 14A-01. If a water immersion seal

has been fitted, either leave the adaptor in position

or fit the plastic mandrel until the crankshaft pulley

can be fitted.

5Fit the drive belts, operation 23A-03 and adjust

the belt tension, operation 23A-02.

6Fit the fan, operation 21A-04.

5

4

a

a

3

2

1

6

PA127

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

1

PA128

Perkins Phaser/1000 Series, April 1995 15A.05

Loading...

Loading...