13 PISTON AND CONNECTING ROD ASSEMBLIES

General description

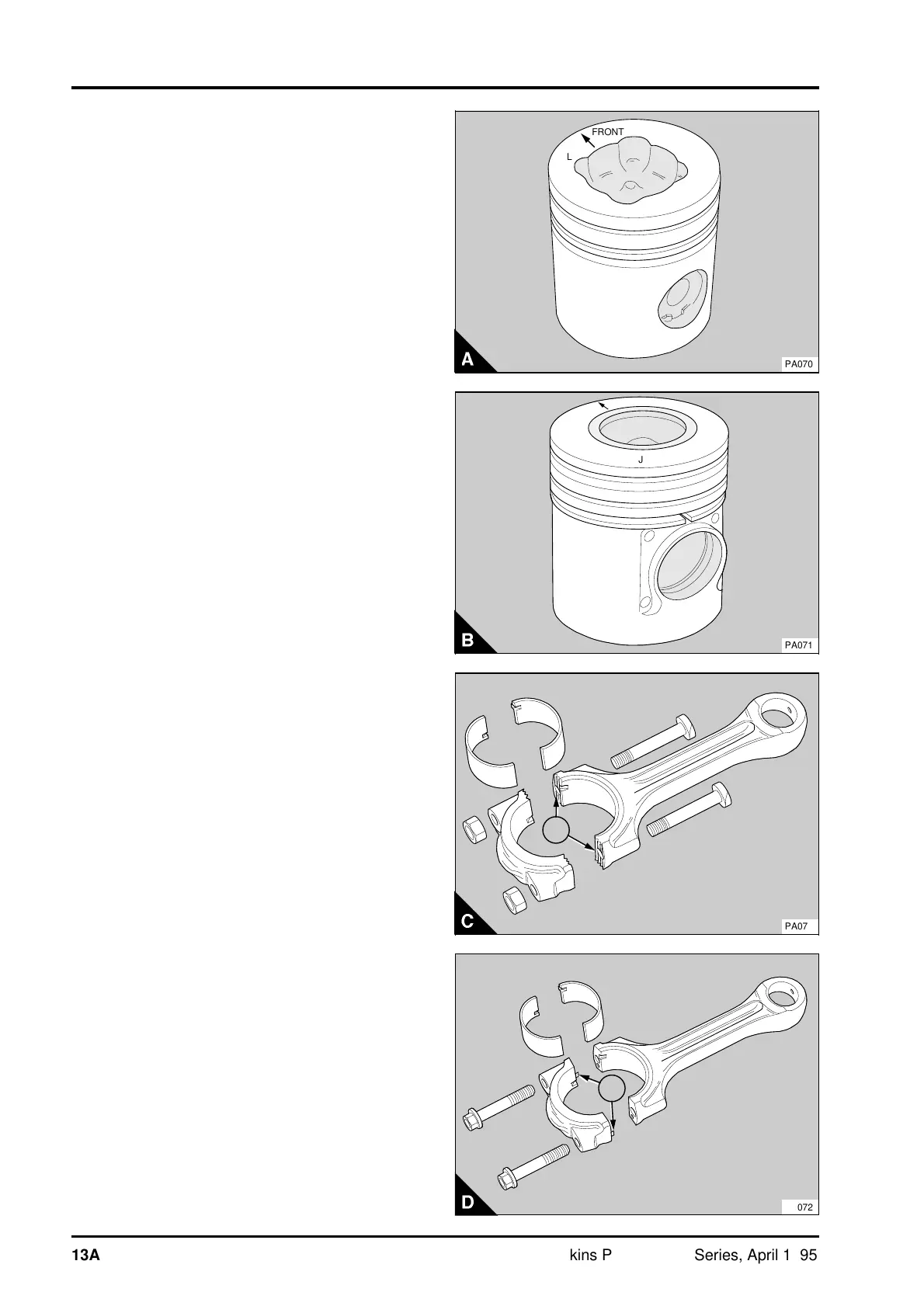

The pistons used in Phaser and 1000 Series

engines have either a "Quadram" (A) or a

"Fastram" (B) combustion chamber in the top of

the piston. These combustion chambers are

designed to give an efficient mix of fuel and air.

The latest engines have pistons, with a "Fastram"

combustion chamber and are available with different

height grades.

The pistons have two compression rings and an oil

control ring. The groove for the top ring has a hard

metal insert to reduce wear of the groove. Axial

location of the fully floating gudgeon pin is by

circlips.

Expansion controlled pistons have a steel insert in

the piston skirt.

Turbocharged engines which are rated higher than

2300 rev/min have an anodised area on the top

face of the piston.

Turbocharged engines have cooling jets fitted in the

cylinder block to spray lubricating oil onto the inner

surface of the pistons.

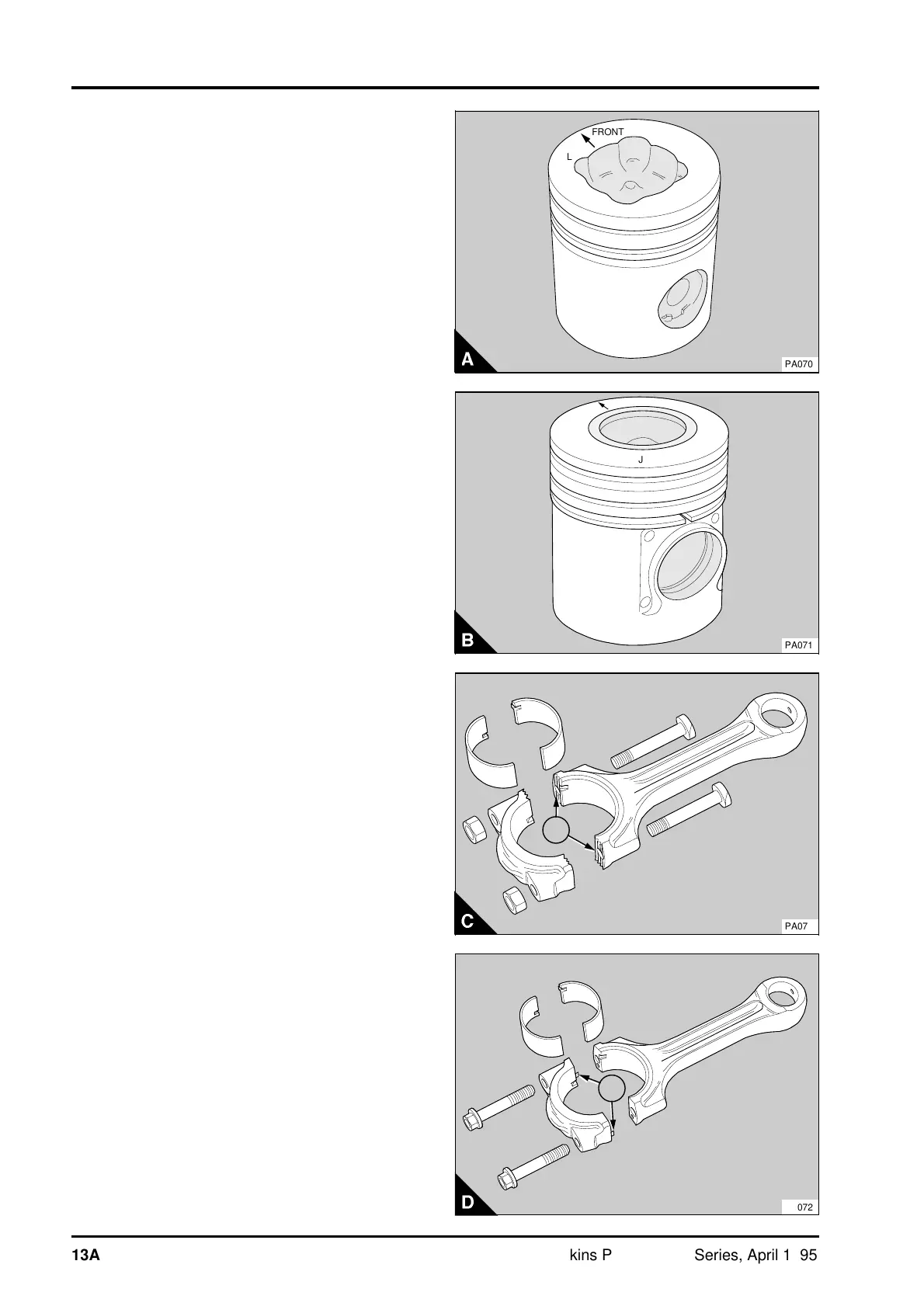

The connecting rods are machined from "H"

section forgings of molybdenum steel. The

connecting rods of turbocharged engines have

wedge shaped small ends. Generally, the location

of the bearing caps to the connecting rods is made

by serrations (C1) and the cap is retained by two

nuts and bolts (C).

On some turbocharged engines, used in vehicle

applications, the location of the bearing cap to the

connecting rod is made by dowels (D1) fitted in the

bearing cap (D). The faces of these connecting

rods and caps are flat and the caps are retained by

two setscrews.

Note: Always use the engine identification number

to order new parts.

a

a

a

a

a

FRONT

L

PA070

J

PA071

PA073

a

a

a

1

a

a

13A.02 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...